4

Congratulations on your purchase of an ANNEALING MADE PERFECT annealing

system. We are confident you will have as many hours of satisfaction using this

machine as we have had creating it. ANNEALING MADE PERFECT has been

designed from the ground up as a system which eliminates human error and the

need for re-calibration between cartridges, giving you the confidence of accurate,

repeatable results every time.

The Annealing Made Perfect annealer is ready to use right out of the box with

no assembly required. NOTE: When installing the four feet, do not over-tighten.

finger-tight is sucient.

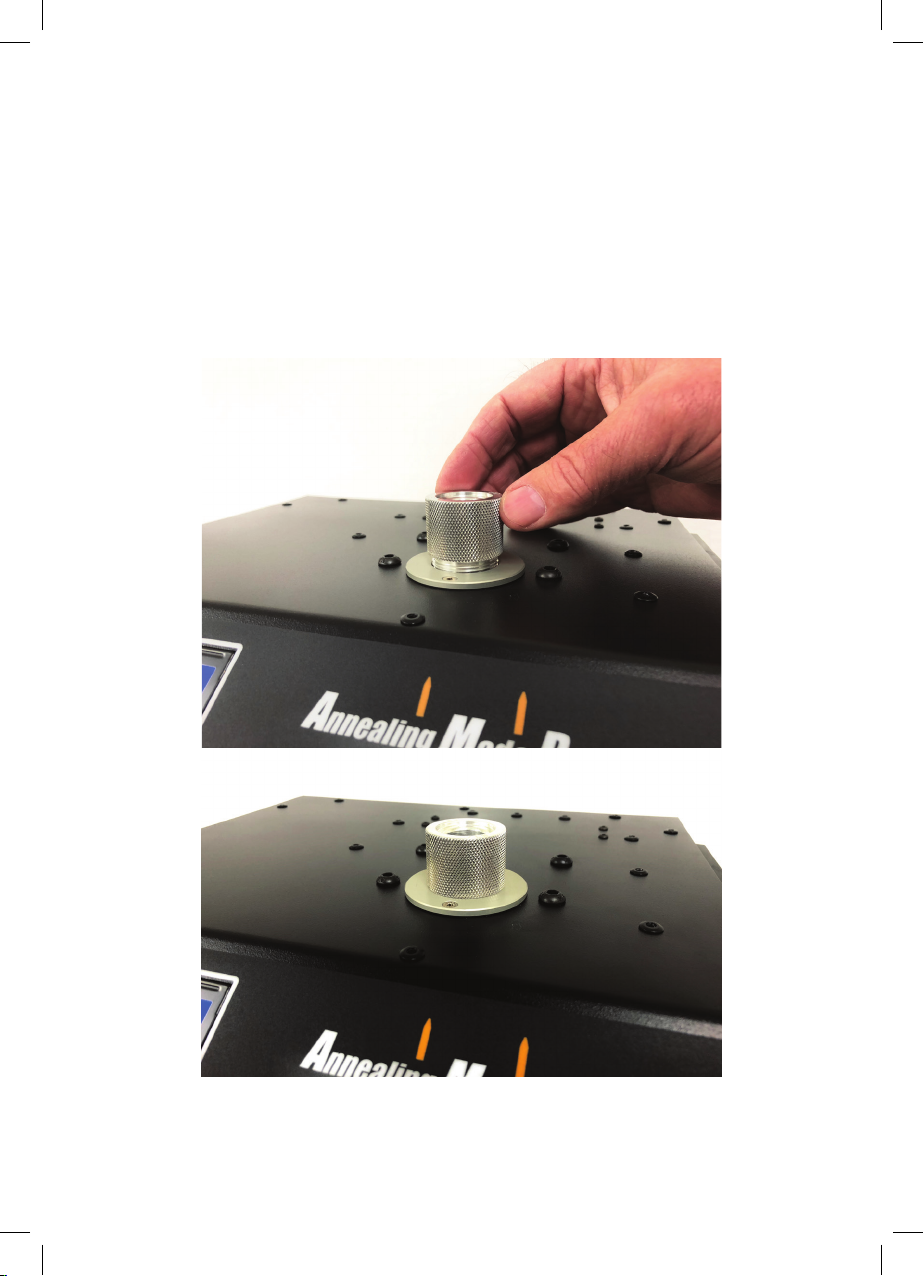

No tools are necessary for operation except for cartridge specific shell holders

(not provided) to insert the cartridges into the machine. When using the annealer

ensure it is on a level surface free from dust or debris, preferably in a cool, dry

and well ventilated room. Do not use in direct hot sunlight.

Use only the power cable supplied with the unit. Plug it into the power socket on

the rear of the annealer and turn on using the red switch on power cable socket.

Also supplied is a USB cable. When future software updates are available, this

can be plugged into the port on the left hand side of the annealer to connect with

a computer.

The annealer has preloaded programs for each cartridge and care must be taken

to ensure the correct program is used to prevent damage to cartridges and or

property. The annealer is designed for BRASS CARTRIDGES ONLY.

Nickel plated brass cases are fine.

All program/pilot combinations can be found on our website:

www.ampannealing.com/settings

WELCOME