Introduction

Product Overview......................................................... 1

Features ....................................................................... 1

Fume Hood Interface (FHI) Features ........................... 2

Sidewall Sensor (SWS) Features .................................. 2

Sash Position Sensor (SPS) Features ........................... 2

Presence Sensor (FPS) Features .................................. 2

Installation and Mounting Instructions

Fume Hood Controller (FHC) Installation & Mounting.. 3

Fume Hood Location Considerations ........................... 4

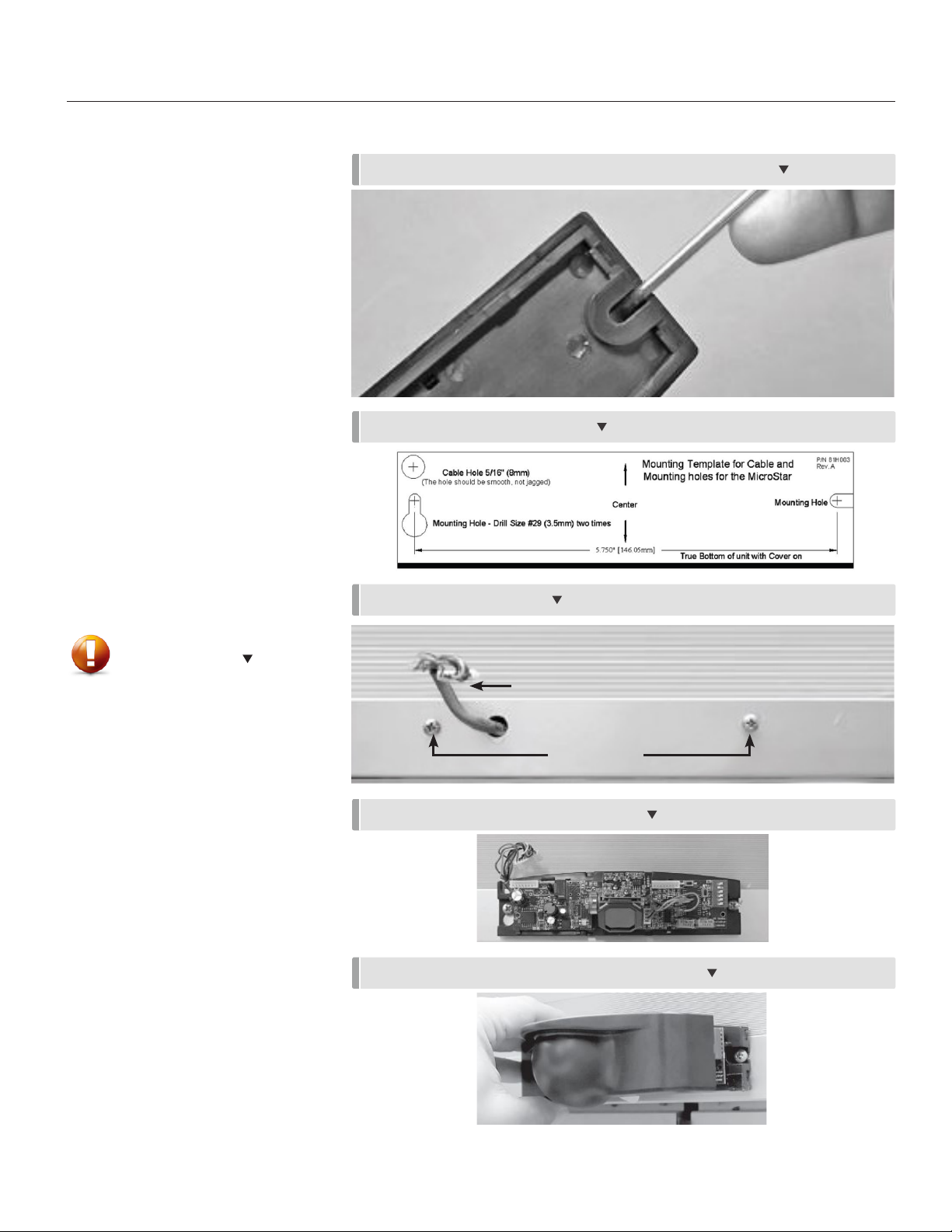

Sash Position Sensor (SPS) Installation & Mounting.... 5

Sidewall Sensor (SWS) Installation & Mounting........... 7

Presence Sensor (FPS) Installation and Mounting ...... 8

Fume Hood Interface Installation ................................ 9

Wiring Diagram .......................................................... 10

Networking and Setup

Fume Hood Network (FHN) ....................................... 11

BACnet MS/TP Network............................................. 12

Sash, Sidewall & Hybrid Configuration

Control Settings.......................................................... 13

VV Application – Interface And Menus

Fume Hood Interface (FHI) ........................................ 14

FHI - Initial Start Up .................................................... 14

Information Menu....................................................... 15

Service Menu............................................................. 15

Control/Monitor .......................................................... 16

Alarm Points ............................................................... 18

Occupancy ................................................................. 18

Input ........................................................................... 19

Output ........................................................................ 20

Network ..................................................................... 22

FHI Setup ................................................................... 22

Diagnostic .................................................................. 23

VV Application – Setup Wizard

Setup Wizard .............................................................. 24

VV Application – Balance And Verification

Balance and Verification.............................................. 26

Balance and Verification - Airflow ............................... 26

VFX Application

Introduction ................................................................ 27

VFX Application – Interface And Menus

Fume Hood Interface (FHI) ......................................... 28

FHI - Initial Start Up .................................................... 28

Information Menu....................................................... 29

Service Menu............................................................. 29

Control/Monitor .......................................................... 30

Alarm Points ............................................................... 32

Occupancy ................................................................. 32

Input ........................................................................... 33

Output ........................................................................ 34

Network ..................................................................... 36

FHI Setup ................................................................... 36

Diagnostic .................................................................. 37

VFX Application – Setup Wizard

Setup Wizard .............................................................. 38

Sash Menu ................................................................. 38

VFX Application – Balance And Verification

Balance and Verification.............................................. 40

Balance and Verification - Airflow ............................... 40

Maintenance

Troubleshooting.......................................................... 41

Replacement Parts ..................................................... 42

Technical Support ....................................................... 42

FUME HOOD CONTROLLER

TABLE OF CONTENTS

IMPORTANT NOTES

CAUTION

This mark indicates an important point for the proper

function of the fume hood and the FHC. Improper

installation or setup may cause unit failure and

contamination of the laboratory space. Pay close attention

to all caution points throughout this manual.

For local area support, please

contact your local Antec Controls

Representative

For more information visit

AntecControls.com