Operating Manual – Digital Frequency Converter Page 6 of 14

09/99 R0048GB.doc

Antriebstechnik GmbH

123

20

40

60

0

0

Pv[W]

Ia[A]

3. Specification FU 3 AE - 03

for application compliant with UL (UL 508) and CSA regulations

Input voltage: UNetz 3x 400 VAC -10% ... 480 VAC +6%; 50/60 Hz

Rated input current: IN3x 3 AAC

Peak input current: 3x 5 AAC

Connection power: 2,1 kVA

Fuse external: 3x 10 A Z-Characteristic, e.g.. ABB S283-Z10

24 VDC supply external: 24 VDC ±20% current consumption ca. 0,4 A

fuse 1 A intern

Nominal output voltage: Ua0 ... Ue

Nominal output current Ia3x 3 AAC

Peak output current: 3x 5 AAC

Output frequency: fout 0 ... 160 Hz

Frequency resolution: 200 Steps relevant to output frequency

Nominal output power: S 2,1 kVA

min. output inductivity:: L 2 mH

Control range pulse generator 1:100

(Graduations > 100)

Efficiency at nominal load: ca. 95%

Power loss at no-load: ca. 20 W

Power loss nominal load: ca. 60 W

Clock frequency of output

transformer:: ca. 3,9 kHz

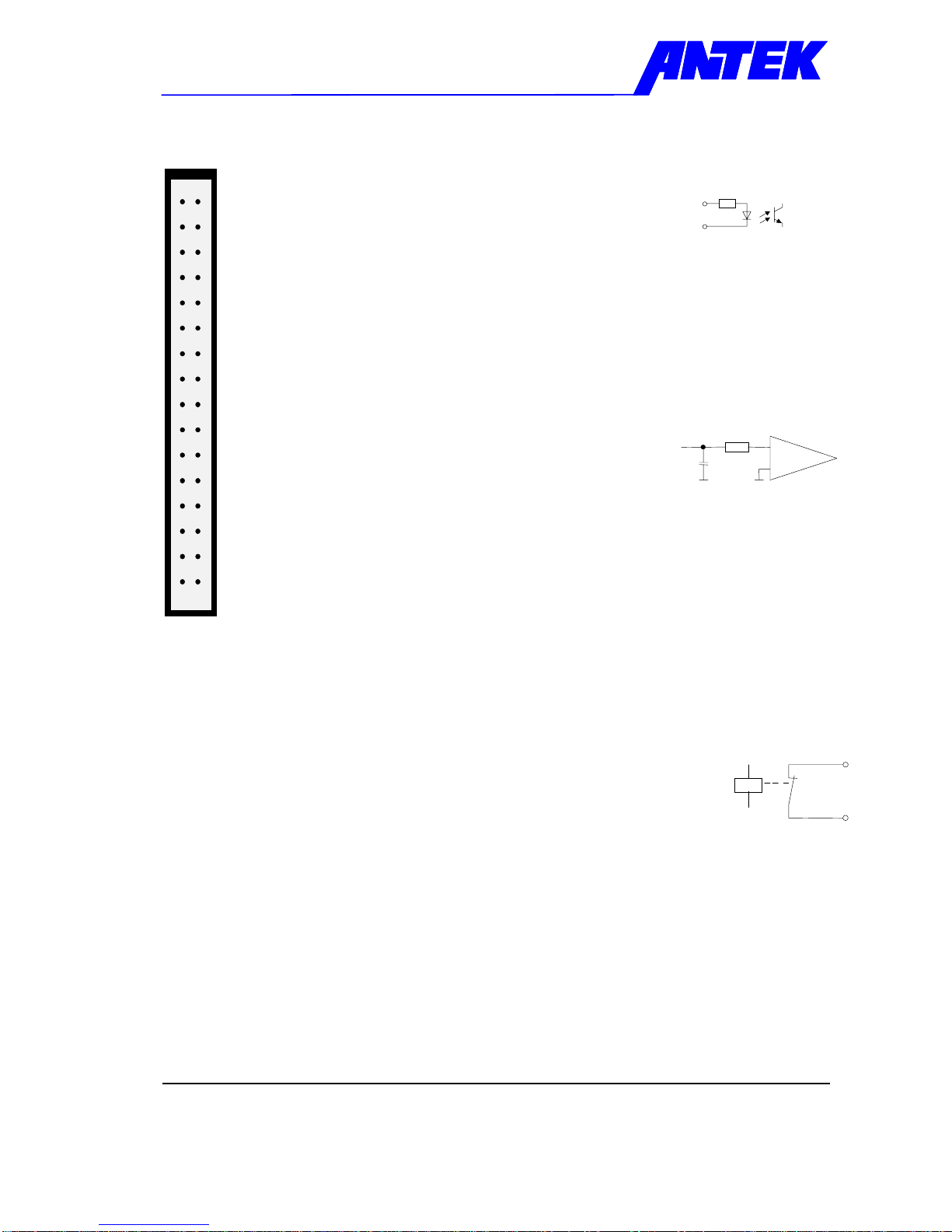

Digital Control inputs: Reglerfreigabe, Reset-Fault

Outputs: Potential-free signal output for

actual / nominal monitoring, ready

Max. load: 35 VDC; 0,2 A

Set point input: 0 ... 10VDC

Actual r.p.m. feedback: Pulse generator 24VDC

Installation: card rack, cooling plate vertical

Ambient temperature: 5 ... 40 °C

Cooling: Ducted cooling 60 m³/h

Connection: Power plug E-L12 form H11

Card connector GDS-AC32 form C

SUB-D 9 pole (female)

Degree of protection IP 00

Geometry: 19“ plug-in module, 3 HE x 19 TE, depth ca. 190 mm

Standards and instructions: DIN 57110b

EN 60204

EN 55011b only with main filter A395

UL-Approbation File E181898

Note:

There is no fuse in the unit for the main supply. Always fit an automatic circuit-breaker with 3 x 10 A Z

characteristic, otherwise the unit is not protect.

Technical Specifications applicable by 400 VAC mains input voltage