AST, AST-L, and AST-PLUS Models 7 Anthony Lifgtates, Inc.

800-482-0003 www.anthonyliftgates.com

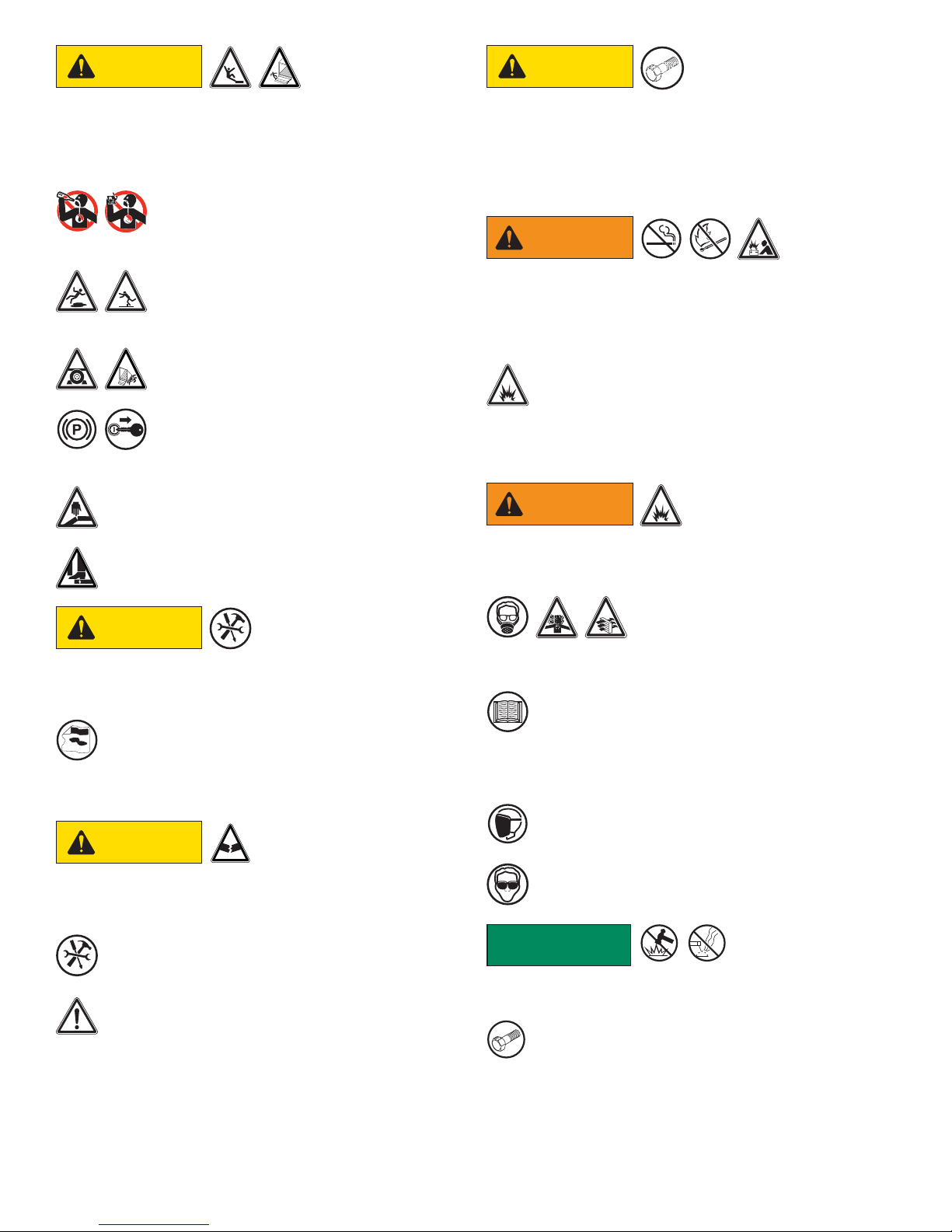

CAUTION Anthony Liftgates

recommends not

riding the liftgate;

however, if the operation requires it, make sure your

footing is stable before raising or lowering the

platform. Always stand away from the edge. When on

the ground, always stand clear of the liftgate when it

is operating.

Do not attempt to maintain the liftgate

under the influence of drugs or alcohol.

Consult your doctor before using the

liftgate while taking prescription medications.

To prevent personal injury, clean up any

spilled fluids immediately. To avoid

tripping, do not leave tools or

components laying around in the work area.

Failure to prevent the truck from moving

during the maintenance of the liftgate

could result in a serious crushing injury.

Always use/set the truck’s parking brake

and remove the ignition key before

servicing the liftgate. Failure to follow

this recommendation can result in injury.

Do not place hands or feet in pinch points.

Do not place your feet under the liftgate or

between the platform and floor extension.

CAUTION To prevent injury, the

liftgate and its related

components should only

be maintained by a qualified installer having knowledge

and skill in using a lifting device, a cutting torch, and

welding equipment.

N

I

NG

AR To prevent possible injuries due to improper

operation, make sure all decals are attached to

the liftgate and/or truck and are legible at all

times.

2.3.2 Equipment / Tools / Parts

CAUTION Do not operate this unit if

it is damaged. If you

believe the unit has a

defect, which could cause it to work improperly,

you should immediately stop and remedy the

problem before continuing.

Make sure the liftgate or truck will not be

damaged or made unsafe by the maintenance

or use of the liftgate.

Never secure the power cable to anything

which allows it to contact sharp edges, other

wiring, fuel tank, fuel lines, brake lines, air

lines, exhaust system, or any other object that could

cause the power cable to wear or be damaged. A cut

battery cable can cause sparks and/or component

damage resulting in loss of vehicle control, serious

injury, or even death.

CAUTION OEM

If replacement parts are

necessary, genuine

factory OEM replacement

parts must be used to restore the liftgate to the

original specifications. Anthony Liftgates will not

accept responsibility for damages as a result of using

unapproved parts. If non-OEM replacement parts are

used, the warranty will be voided.

2.3.3 Battery / Fuel Tank Safety

WARNING To prevent

serious

bodily injury,

keep sparks, lighted matches, and open flames away

from the top of the battery, because battery gas can

explode. Always follow all the manufacturers’ safety

recommendations when working around the truck’s

battery.

Take precautions to avoid sparks coming into

contact with the truck’s fuel tank, brake lines,

or other flammable components. Sparks can

cause an explosion of combustible materials, resulting

in serious injury or death.

2.3.4 Cutting Torch / Welding Safety

WARNING Take precautions to avoid

sparks from contacting

the truck’s fuel tank, brake

lines, or other flammable components. Sparks can

ignite combustible materials, resulting in serious

injury or death.

Always weld or use a cutting

torch in a well ventilated area and,

if in an enclosed area, vent the

fumes to the outside. Breathing welding smoke and

paint fumes can cause serious injury.

Always follow all State and Federal health and

safety laws and/or local regulations when using

an arc welder, mig welder, or cutting torch. Also,

follow all manufacturers’ safety guidelines. If other

people are present during the installation of the liftgate,

make sure the assembly area is shielded from their view.

To avoid eye injury during welding, always

wear a welding helmet with the proper lens to

protect your eyes.

To avoid eye injury while using a cutting torch,

always use eye protection with the proper lens

to protect your eyes.

SAFETY

INSTRUCTIONS

Do not modify safety

devices. Do not

weld on the liftgate

assembly, except the adapter frame tube. Unauthorized

modifications may impair its function and safety.

Make sure all parts are in good working

condition and properly installed. Replace any

damaged parts immediately.