P/N 1011504 Rev B 11/18

10

Monthly Cleaning

This unit utilizes an open steam

generator. When introduced, water

immediately vaporizes creating a burst

of steam, leaving behind any minerals

that had previously been dissolved.

Though a small amount of minerals are

necessary for proper operation, exces-

sive amounts will cause poor steaming

and may damage the generator.

1. Press the Power button to turn the

unit o. The unit enters a cool-

down mode and will shut down

automatically.

NOTICE:You do not need to wait until

the cool down mode completes.

However, the unit will be hot so

wear heat resistant gloves dur-

ing cleaning.

2. Put on heat resistant gloves and

remove the items in Figure 4.

3. Wash, rinse, and sanitize the items

removed at the sink. Allow to air

dry.

4. Wipe the exterior of the unit and

the inner part of the basket cavity

with a clean, sanitized towel. Clean

up any spills completely. Allow to

air dry.

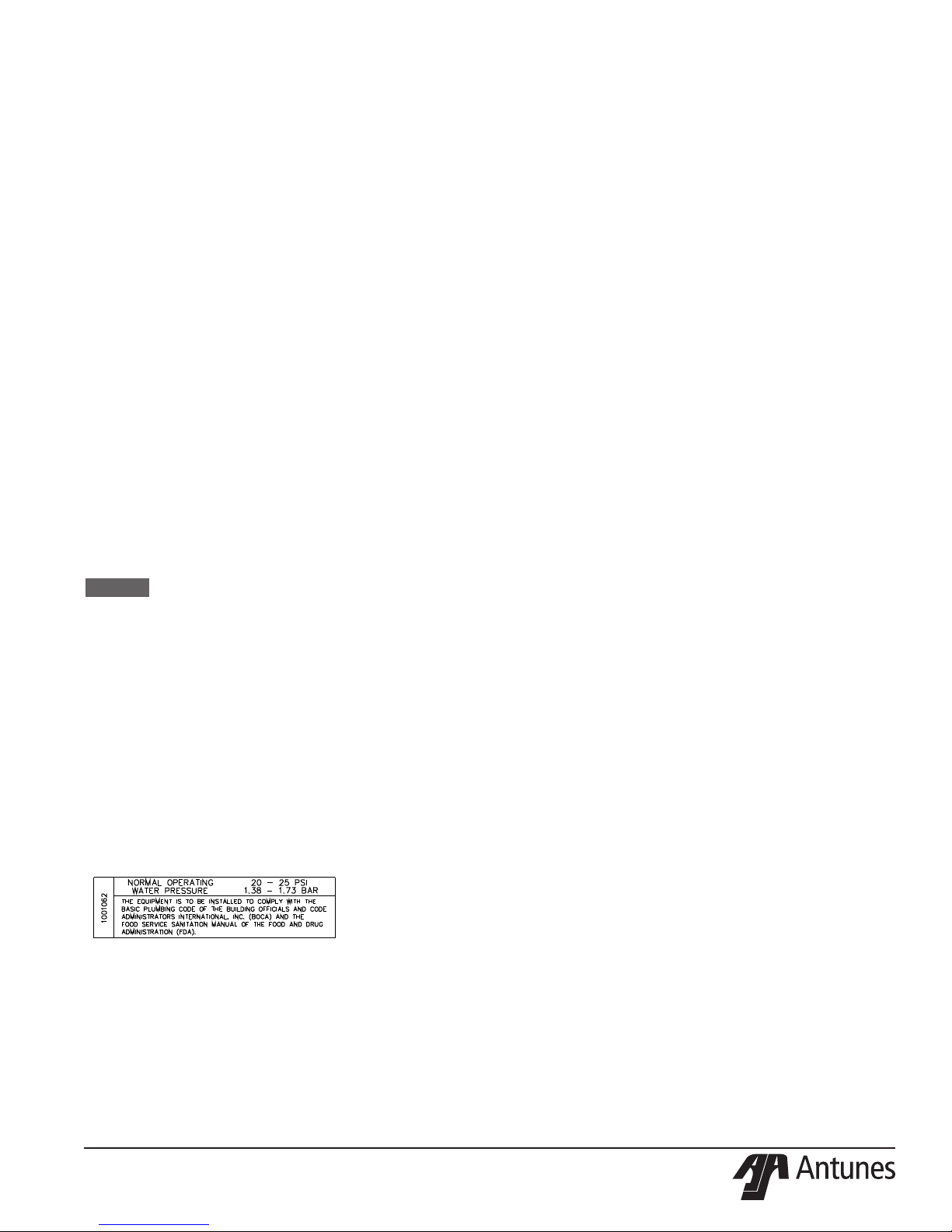

5. Remove wing nut and generator

cover assembly, generator gasket,

and diusers (Figure 5).

6. Examine all steam generator

orices (holes). If mineral deposits

have formed, place a at blade

screwdriver into openings. Use a

twisting motion to scrape openings

clean.

NOTICE: Mineral deposits come o in

“akes” or in layers if the build-

up is excessive.

7. Use an abrasive cleaning brush

and small scraper to remove de-

posits from the generator surface.

8. Pour delimer solution (not sup-

plied) onto the generator surface

and allow to soak for one hour.

NOTICE:Be sure to Follow the usage

instructions on the delimer

packet.

9. Remove the delimer solution from

the generator and rinse with clear

water to remove traces of delimer.

NOTICE:To ensure proper steaming

characteristics some mineral

deposits must be present on

generator casting.

If during cleaning, the gen-

erator does become free of

mineral deposits, add ordinary

tap water (non reverse osmosis

or ionic lter system) to casting

and allow to boil o.

NOTICE:In soft water areas, it may

be necessary to add a small

amount of lime to generator

to “season” it. This will ensure

proper steaming characteristics

by producing a thin coating of

mineral deposits on the casting.

Seasoning mixture consists of

75 ml. (2-1/4 oz.) baking soda,

75 ml. (2-1/4 oz.) lime, and 1

gallon water. Pour 1/4” deep

of seasoning mixture into a

cold generator. Turn the unit

on. After mixture is converted

to steam, the remaining loose

powder is removed and genera-

tor cleaned.

10. Wipe the exterior of the unit and

the inner part of the basket cavity

with a clean, sanitized towel. Allow

to air dry.

11. Re-install the diusers, generator

cover, generator cover bracket and

secure with the wing nut.

12. Re-install all items removed in

Step 2.

Figure 5. Steam Generator

Support Channel

Generator Cover

Assembly

Wing Nut

Diffusers

Steam Generator

Checking and Cleaning Water

Strainer

To ensure proper and consistent

steaming results, inspect the water ow

regulator and strainer cup regularly.

If the water pressure on the gauge

has dropped, visually check the clear

plastic strainer cup and clean out the

accumulated debris as follows:

1. Shut o the water supply valve to

the unit. Unscrew the clear plastic

strainer cup and carefully remove

the mesh strainer screen.

2. At the sink, gently ush all of

the accumulated debris from the

strainer cup and mesh strainer

screen. Be especially careful not to

damage the mesh strainer screen.

3. Carefully place the mesh strainer

screen into its seat at the bottom

of the clear plastic cup and conrm

that the O-ring is properly seated

in its place before screwing the

strainer cup and top back together.

4. Purge the air out of the strainer

tubing by disconnecting the male

quick disconnect tting from the

equipment and, over a bucket,

pushing its valve core in until there

is a good water ow.