4

Call: 336-547-9338 or visit: anuainternational.com

Reference Manual

3.3 Cle r W ter Pump

The clear water pump (discharge pump) is an integral part of the system. This is

advantageous since the SBR is essentially a primary tank, treatment unit, and pump

tank all-in-one. The pump provides timed dosing for a downstream component

such as a polishing filter or drainfield. The standard kit contains a typical 0.5 HP

effluent pump. A larger pump can be included in the kit where required. The clear

water pump can be used to discharge to the following:

Polishing unit such as the Puraflo peat fiber biofilter with optional pad dispersal

ravity trench or bed

Low Pressure Pipe (LPP) drainfield

Drip irrigation

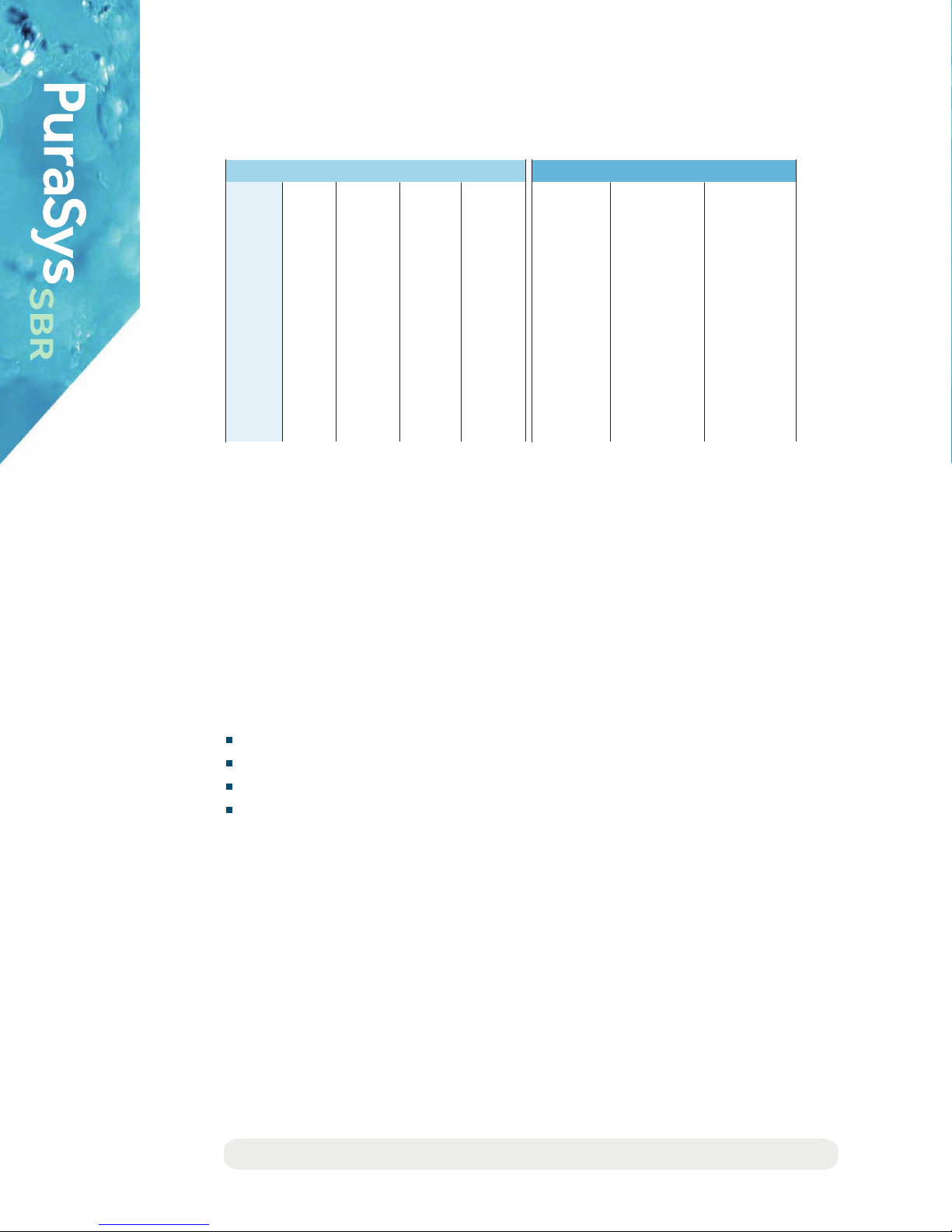

3.2 Pur Sys SBR Re ctor T nk Sizing

N TE: The minimum and maximum volumes in these tables are guidelines for standard kits.

The volumes can vary from the values in the table. Consult with Anua for alternate designs.

_________________________________________________

NSF Reactor Tank Sizing (gallons)

_________________________________________________

_________________________________________________

PS1-4 400 605 545 665

_________________________________________________________________________________________________________________________

PS1-5 500 756 681 832

_________________________________________________________________________________________________________________________

PS1-6 600 908 817 998

_________________________________________________________________________________________________________________________

PS1-7 700 1,059 953 1,165

_________________________________________________________________________________________________________________________

PS1-8 800 1,210 1,089 1,331

_________________________________________________________________________________________________________________________

PS1-9 900 1,361 1,225 1,497

_________________________________________________________________________________________________________________________

PS1-10 1,000 1,513 1,361 1,664

_________________________________________________________________________________________________________________________

PS1-11 1,100 1,664 1,497 1,830

_________________________________________________________________________________________________________________________

PS1-12 1,200 1,815 1,634 1,997

_________________________________________________________________________________________________________________________

PS1-13 1,300 1,966 1,770 2,163

_________________________________________________________________________________________________________________________

PS1-14 1,400 2,188 1,906 2,329

__________________________________________________

Model Minimum Maximum

Flow

(gpd)

Reactor

Tank Size

___________________________________________

Anua Recommended Reactor Tank Sizing (gallons)

___________________________________________

___________________________________________

400 240 320

__________________________________________________________________________________________________________

500 300 400

__________________________________________________________________________________________________________

600 360 480

__________________________________________________________________________________________________________

700 420 560

__________________________________________________________________________________________________________

800 480 640

__________________________________________________________________________________________________________

900 540 720

__________________________________________________________________________________________________________

1,000 600 800

__________________________________________________________________________________________________________

1,100 660 880

__________________________________________________________________________________________________________

1,200 720 960

__________________________________________________________________________________________________________

1,300 780 1,040

__________________________________________________________________________________________________________

1,400 840 1,120

_______________________________________________

Peak Design

Flow (gpd)

Minimum,

Approximate

Maximum,

Approximate

Table 1

Anua_PuraSys_RefManual_063016_Anua_PuraSys_RefManual 6/29/16 4:41 PM Page 5