AOM AUSTRALIA

22/54 BEACH ST KOGARAH NSW 2217 Tel 1300 903 788 Fax 1300 904 088

www.a maus.c m.au Email inf @a maus.c m.au

Page 2 of 13

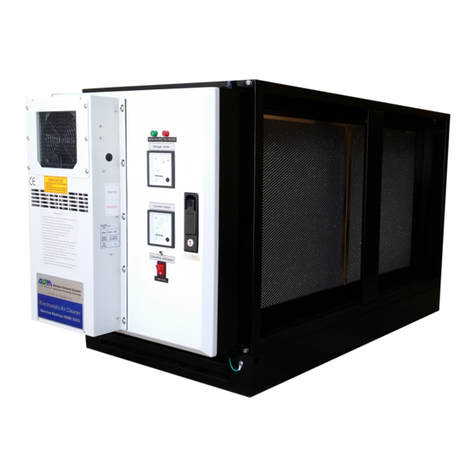

ELECTROSTATIC FILTERS- EAN- 200/300/400/600/600T/800T/1200T

SPECIFICATIONS AND DIMENSIONS

MOD L 600T 2 x 300s ON TOP OF ACH OTH R 2830 L/s

MOD L 800T 2 x 400s ON TOP OF ACH OTH R 3780 L/s

MOD L 1200T 2 x 600s ON TOP OF ACH OTH R 5660 L/s

1. PR -FILT R: it stops large particles of grease and fumes

entering the ionization section stainless steel mesh. asy to

clean.

2. HIGH VOLTAG IONIZATION S CTION:13 KV Tungsten ionizer

wires are spring-mounted within an aluminium frame. In this

section, the grease/fumes particles receive an electrical

charge.

3. COLL CTION PLAT S: this section is made of a series of equally

spaced parallel plates attracting the charged particles. Then

they slide down the plates and drop into a removable tray.

4. SPRING: they connect the power from the power supply to the

unit.

5. POW R SUPPLY: it supplies the high voltage to the two stages

of the electrostatic precipitation unit.

6. GR AS COLL CTION TRAY: the tray is removable for easy

cleaning.

7. LOCK: unlock it to access the electrostatic precipitation unit.

8. LIGHTS & ON/OFF SWITCH: when the green light is on, this

means that the unit is working properly. When the red light is

on, it indicates that the unit needs to be cleaned or serviced.

9. AMP R M T R: it shows the unit consumption in milliamps.

10. CABIN T: 16 gauge steel housing with powder coated paint.

11. VOLTM T R

12. H AT XCHANG R: keep the electronics at the right

temperature.

NOTES:

FOR CHARCOAL & CHAR-GRILL COOKING, CONSULT OUR NGIN RS FOR CORR CT SIZING

WH N ORD RING A UNIT FOR OUTDOOR INSTALLATION, PL AS ADVIS AT TIM OF PURCHAS AND CONN CT TH POW R CORD TO A

W ATH R-PROOF SWITCH

FOR AIR-VOLUM HIGH R THAN 5660 L/S CONSULT OUR NGIN RS