AOMAUSTRALIA

21/54BeachStreetKogarahNSW2217TelSales1300903788Service1300904088

rev1,22/09/2016 1

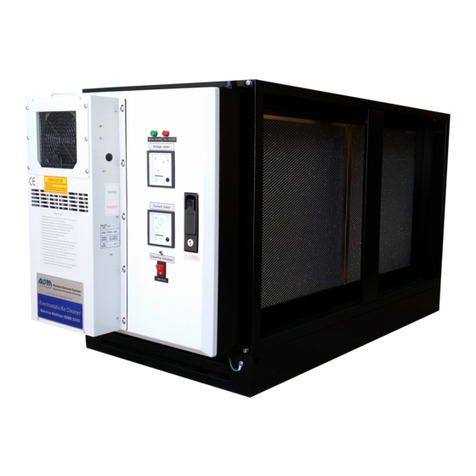

AOMEANELECTROSTATICFILTERS

EQUIPMENTSPECIFICATIONS

Tableofcontents

1DESCRIPTION.......................................................................................................................................................................................2

2GENERALSPECIFICATIONS..................................................................................................................................................................2

3DIMENSIONS........................................................................................................................................................................................4

3.1EAN200.......................................................................................................................................................................................4

3.2EAN300........................................................................................................................................................................................5

3.3EAN400.......................................................................................................................................................................................6

3.4EAN600........................................................................................................................................................................................7

4COMPONENTS.....................................................................................................................................................................................8

5GENERALFUNCTIONOVERVIEW.........................................................................................................................................................9

6CERTIFICATIONANDTESTING............................................................................................................................................................10

7INSTALLATIONGUIDELINES...............................................................................................................................................................11

7.1General.......................................................................................................................................................................................11

7.2Deliveryandhandover................................................................................................................................................................12

7.3Receiving....................................................................................................................................................................................12

7.4Unpacking...................................................................................................................................................................................12

7.5Storage.......................................................................................................................................................................................12

7.6Installationscenarios...................................................................................................................................................................13

7.7Installation..................................................................................................................................................................................13

7.8Accessrequirements...................................................................................................................................................................14

7.9Electricalconnection

...................................................................................................................................................................15

7.10BMSconnection..........................................................................................................................................................................16

7.11PriortoPoweringtheunitON.....................................................................................................................................................16

7.12PoweringtheunitON..................................................................................................................................................................16

8OPERATIONANDMAINTENANCE......................................................................................................................................................17

8.1Priortocookingstart...................................................................................................................................................................17

8.2Cleaning......................................................................................................................................................................................17

8.3Troubleshooting..........................................................................................................................................................................18

9WARRANTYANDCONTACTS..............................................................................................................................................................19

9.1ProductWarranty........................................................................................................................................................................19

9.2Contacts.....................................................................................................................................................................................19

AOMAUSTRALIAASSUMESTHATTHISDOCUMENTHASBEENTRANSFERREDTOTHEPRODUCTOWNERAND

THATTHEOWNERISFULLYAWAREOFITSCONTENT