1007AIRCORONA 3 di 4

NOTA

CHAPTER 3: ADMITTED & NON ADMITTED USE.

THE OPERATOR SAME WILL BE ONLY PERSON RESPONSIBLE OF THE RESPECT OF THE

PRESENT NORM

MACHINE FOR PROFESSIONAL USE DO NOT ALLOW CHILDREN TO OPERATE THE MACHINE

The machine is projected to close bottles of glass type it crowns, with corks crown in metal,

Any other use is forbidden.

DON'T USE TO COVER CONTAINING BOTTLES LIQUID DANGEROUS FOR CONTACT or INALATION

CHAPTER 4: HANDLING & UNPACKAGING OPERATIONS

The AIR CORKER in the standard version is delivered, ready to the use protected from cardboard and

extensible film in plastics.

PLEASE CHECK AT THE MOMENT OF THE HANDLING , THE INTEGRETY OF THE PACK. IF THIS

RESULTS DAMAGED IT WILL BE UNDERLINE THE COURIER AND ANNOTATED ON THE SHIPPING

DOCUMENTS .

THE FIRM BUILDER DOESN'T ANSWER OF DAMAGES DUE TO THE TRANSPORT

The not extortionate weight of 16 Kgs of the machine allows by hand easy moves up to the Area for

the usage. Open the box, remove the block protections to make slowly flow the machine outside of

the box. Remove the protection in plastics.

FOLLOW THE INDICATIONS "TOP-ALTO" "FRAGILE" AND DO NOT TURN UPSIDE-DOWN

THE MATERIAL OF DISCARD OF THE PACK WILL BE QUICKLY SELECTED IN BASE OF THE CE NORMS

CHAPTER 5: PLACE OF WORK-BOTTLES-CLOTHING

AIRCORONA in standard version is a table machine, therefore it is necessary to sufficiently

individualize a plan of laying or a strong table and in plain to be able to fix the same machine. The

corker must have supported away from the edge of the table so that to avoid harmful accidental falls.

We suggest to fix with screw the machine to the table.

5.1 the environment will be well illuminated and dry on the before and on the sides of the machien

must be left completely free.

5.2 CLOTHING The clothing of the operator will include gloves, long hard smock and shoes with anti-

slip soles, to prevent him from fallings or breakings of bottles.

CHAPTER 6: SETTING UP: GENERAL RULES

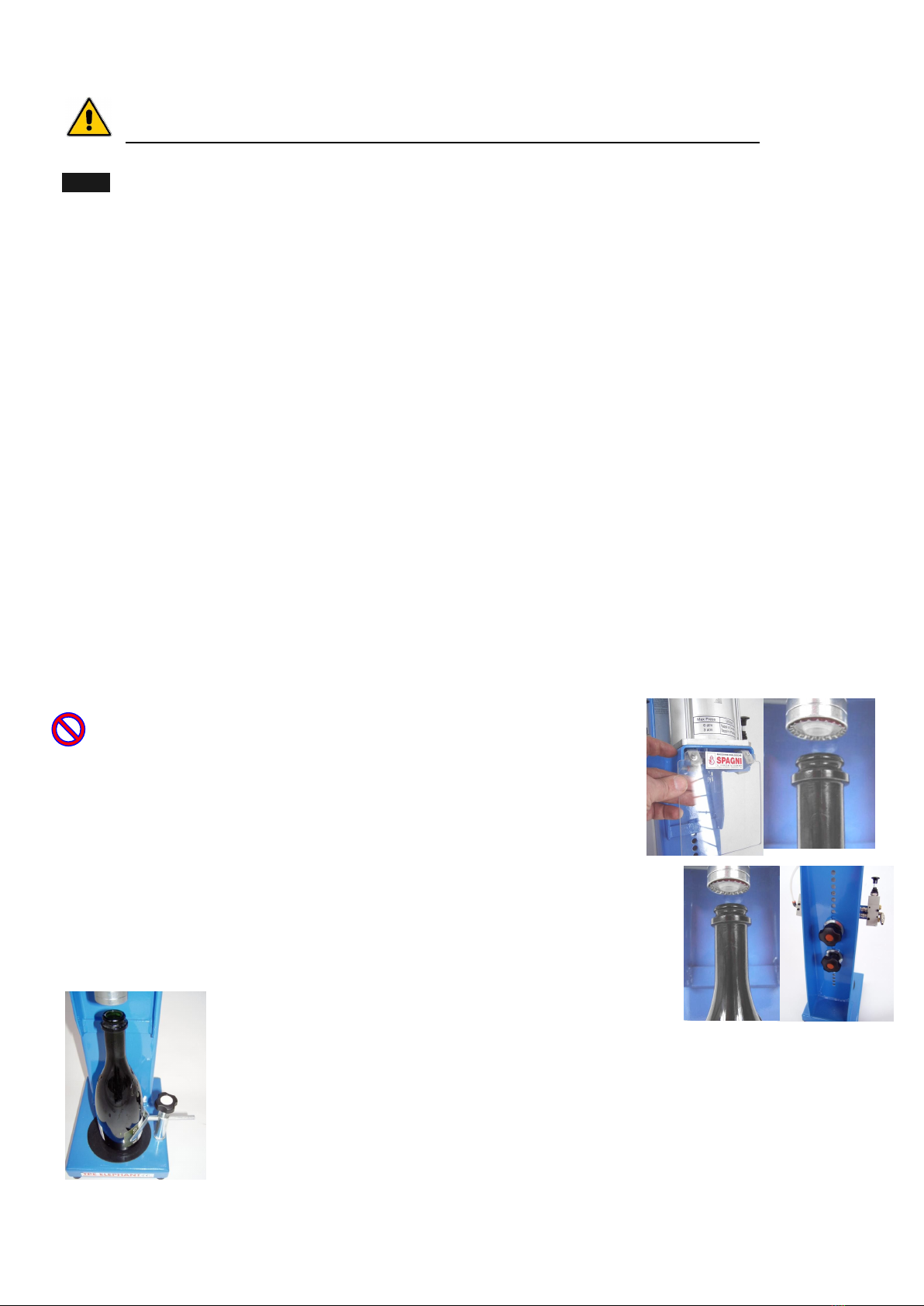

6.1 make sure him that the screws that withhold the protection in

plastics is well fix (fig 3), remove the plastic tape.

6.2 check that the diameter of the cork crowns that intend to use it

corresponds to the climbed on buckle ( boccola ) , in contrary case it is

necessary to set up on the second buckle ( boccola) in endowment fig2.

6.2 feeding Compressed Air to connect the machine to a presser air

that satisfies the minimum requirements: pressure of exercise 8 bar.

We advise to use a presser with 150 liters air inhaled per minute and

compressed air tank than at least 50 liters ability. Consumptiom air for

every cycle to 4,5 bar 7,3n1 (valid pressure for corks up to 24 mms) to 6,5

BAR 10,14 n1 (necessary pressure for corks agglomerations or synthetic).

6.3 SETTING Height Bottle, fig5 ( take place every time that it changes

height of the bottle)

6.3a STAND STILL Machine : detach the attack air. Lay one of the bottles

that intend to cover on the piattello Check that the measure (a) fig5a is

inclusive between 15 and 25mm. If the height doesn't

reenter in the aforesaid measures it is necessary to ask

for the help of a second person for:

6.3b Move up or down the whole pushing group fig5B. Unscrew the handles black

, unthread from the holes the support with attached piston, individualize the new

position of block to insert in the new holes. Tighten well the black handles.

6.4 Registration of Centering Bottle Along the axle X see fig6

6.4a Support one of the bottles that they intends to cover on the base.

6.4.b Loosen the two screws of block center tool , check that the axle X passes to

the center of the bottle. Tighten the screw of block center tool.