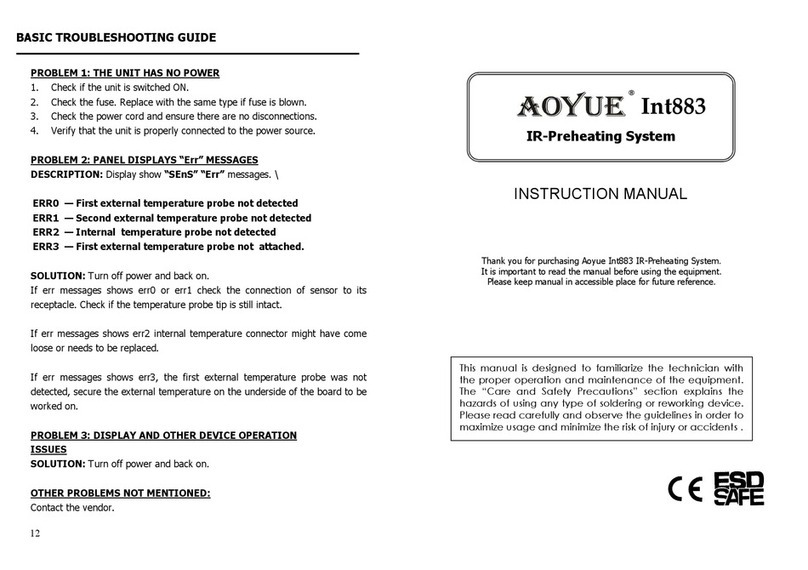

4

!

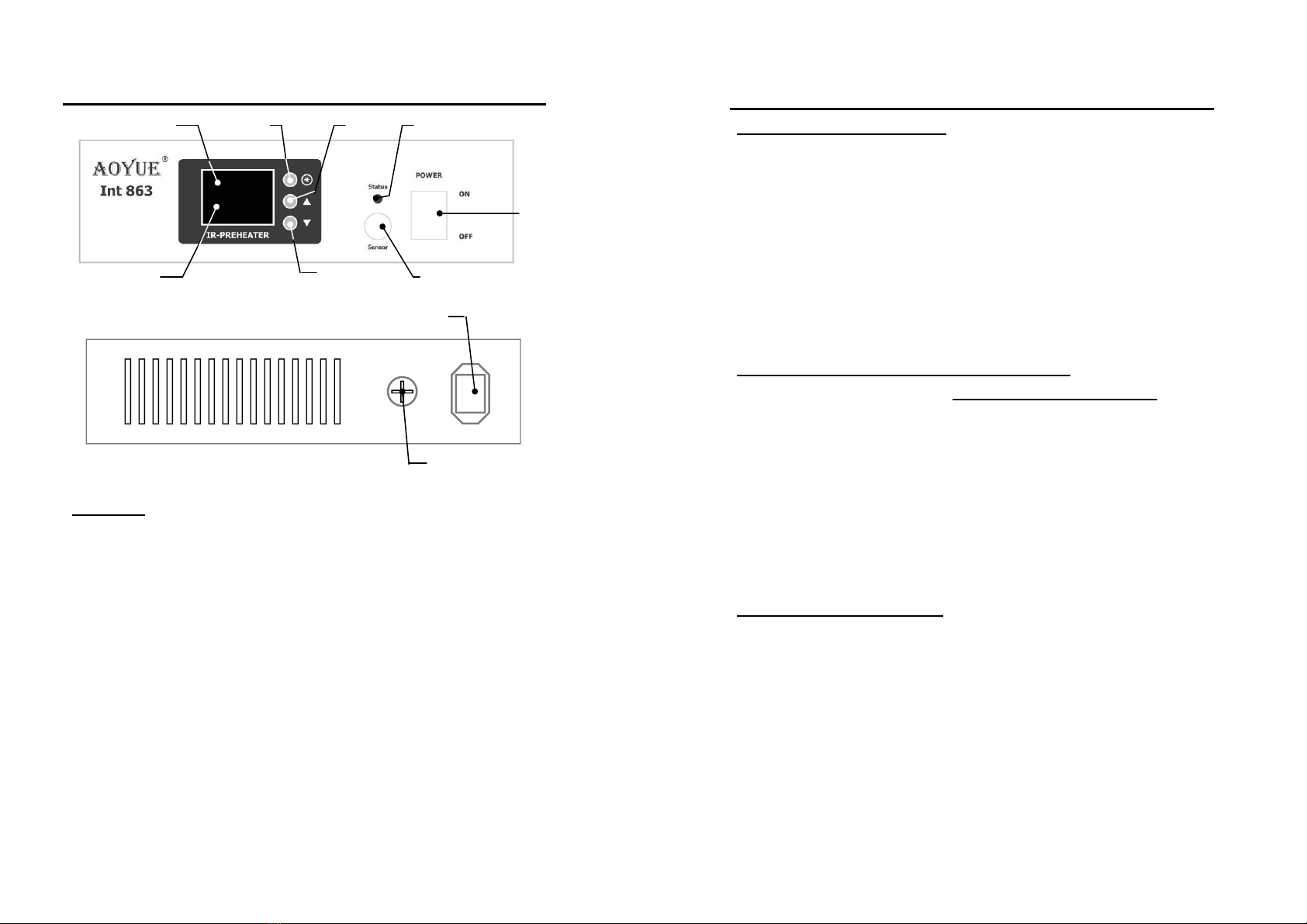

The Aoyue Int 863 IR-Preheating System is a reworking equipment that

combines infrared (IR) heating technology, enhanced pre-heating area, versatile

board holder, and profile control of heating in one sophisticated package. It is

designed for reworking double-sided, diverse technology printed circuit boards

(PCB) which utilizes traditional or lead free solder.

The system is equipped with a high powered IR-heating elements combined

with multiple types of preheating operation with built in safety control of heat

and over heat protection. Finally, the unique, innovative design with digital

control panel offers precision, safety, and ease of use to meet all reworking

requirements.

PRODUCT DESCRIPTION

FUNCTIONS and FEATURES

"! Microprocessor-controlled ESD safe unit.

"! Utilizes infrared heat wave technology.

"! Versatile board holder. To fit various board types

"! Enhanced pre-heating area to fit large PCBs.

"! Widely used for reworking BGAs, micro BGAs,!QFPs, PLCCs, SOICs, small SMD,

and other circuit board components.

"! Large pre-heating area minimizes board warping

"! Easy-to-adjust pre-heat temperatures with digital display.

"! Built in extra temperature sensor for more accurate monitoring of board temperature.

"! Built-in temperature sensor for stable (temperature) measurements.

"! Closed loop system for precise temperature control.

"! Profile adjustment functionality for automating reworking tasks under user de-

fined temperature and time settings.

"! Three modes of operation to suite different reworking requirements.

"! Temperature and Profile settings are stored into CPU memory for easy configu-

ration.

"! Compatible for use with either hot air or IR top heating systems. 9

!

OPERATING PROCEDURES

D. TYPE “1” OPERATION

Before proceeding with this type of operation, attach the first

external temperature probe to the underside of the PCB to be worked

on. The second probe can be placed near areas of interest.

This type of operation utilizes the first external temperature sensor

to control the heat. Using this type of operation allows us to closely

control the temperature at board level. While freeing up the second

external temperature probe for additional monitoring.

1. To set the desired temperature press the selection button

repeatedly until the top display shows “Set”. The bottom display

would show the current set temperature followed by a suffix “A”.

2. Press the increase or decrease button to adjust the set

temperature level. The set temperature is adjustable from 50 to

280 C in this type of operation.

3. For this type of operation we must closely monitor the actual

temperature of the first external temperature probe. To view the

actual temperature readout of this probe repeatedly press the

selection button until the top display shows the word “Act1”,

and the bottom display shows the actual temperature of first

external temperature probe followed by a suffix “b”.

4. To view the temperature of the second external temperature

probe or simultaneously view both external temperature probe's

temperature:

"! Repeatedly press the selection button until the top display

shows “Act 2” and bottom’s suffix shows “c” this displays the

second temperature probe.

"! Repeatedly press the selection button until the top shows the

first temperature probe with suffix “b” and the bottom shows the

second temperature probe with suffix “c”.

5. Under type “1” mode of operation it is not necessary to monitor

the internal temperature sensor’s read out.