4

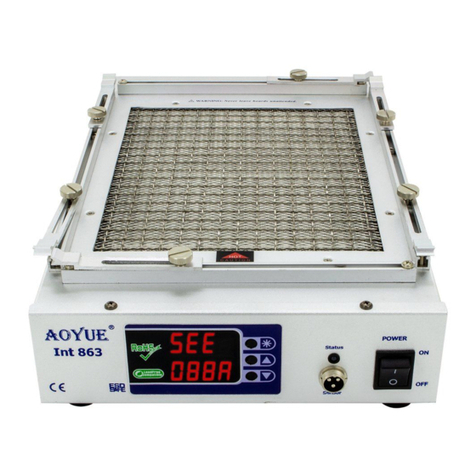

TheAoyueInt883IRPreheatingSystemisareworkingequipmentthatcom

binesinfrared(IR)heatingtechnology,enhancedpreheatingarea,versatileboard

holder,andprofilecontrolofheatinginonesophisticatedpackage.Itis designed

for reworking doublesided, diverse technology printed circuit boards (PCB)

whichutilizestraditionalorleadfreesolder.

ThesystemisequippedwithahighpoweredIRheatingelementscombined

with multiple types of preheating operation with built in safety control of heat

andoverheatprotection. Finally,theunique,innovativedesignwithdigitalcon

trolpaneloffersprecision,safety,andeaseofusetomeetallreworking

requirements.

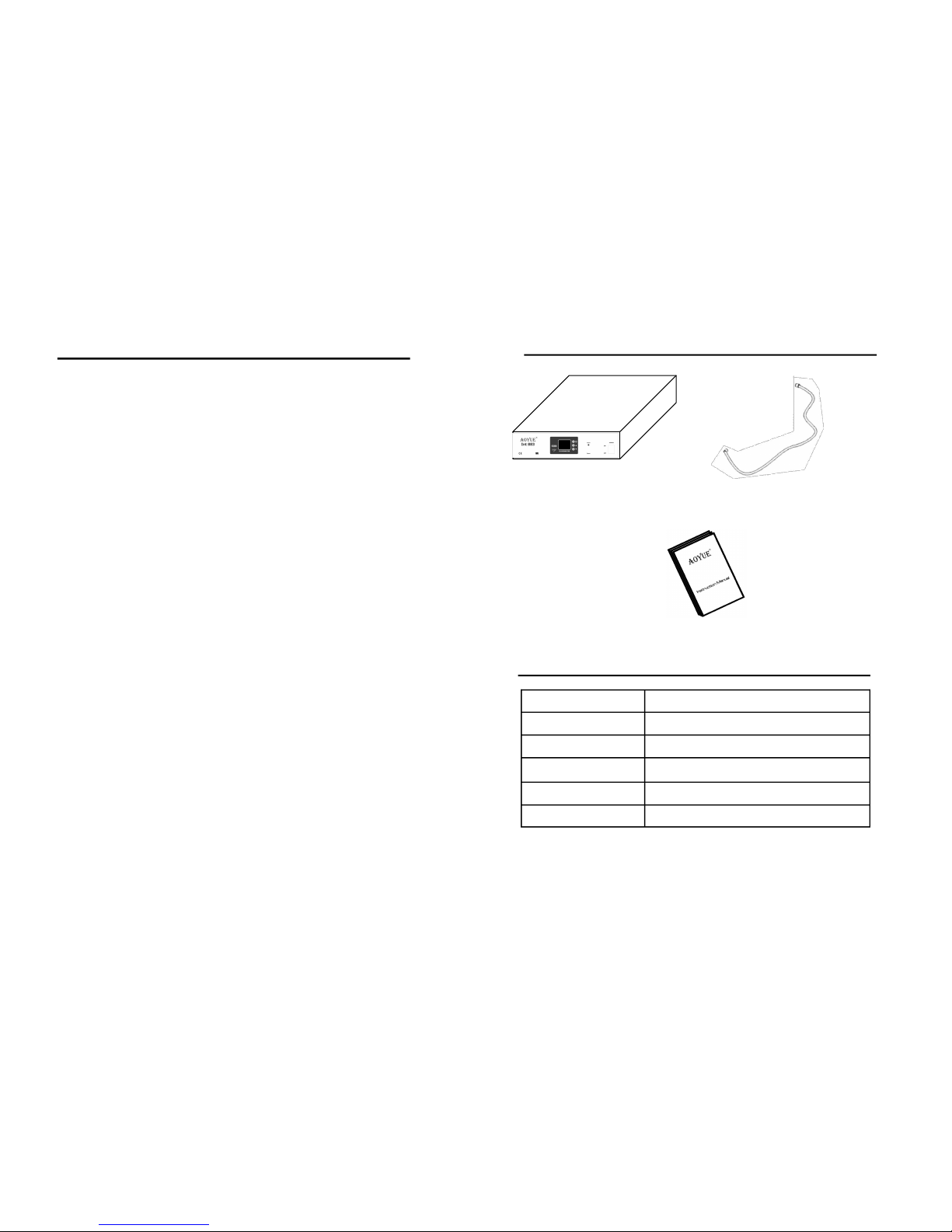

PRODUCTDESCRIPTION

FUNCTIONSandFEATURES

●MicroprocessorcontrolledESDsafeunit.

●Utilizesinfraredheatwavetechnology.

●Versatileboardholder.Tofitvariousboardtypes

●EnhancedpreheatingareatofitlargePCBs.

●WidelyusedforreworkingBGAs,microBGAs, QFPs,PLCCs,SOICs,smallSMD,

andothercircuitboardcomponents.

●Largepreheatingareaminimizesboardwarping

●Easytoadjustpreheattemperatureswithdigitaldisplay.

●Builtinextratemperaturesensorformoreaccuratemonitoringofboardtemperature.

●Builtintemperaturesensorforstable(temperature)measurements.

●Closedloopsystemforprecisetemperaturecontrol.

●Profile adjustment functionality for automating reworking tasks under user

definedtemperatureandtimesettings.

●Threemodesofoperationtosuitedifferentreworkingrequirements.

●Temperature and Profile settings are stored into CPU memory for easy

configuration.

●CompatibleforusewitheitherhotairorIRtopheatingsystems.

9

OPERATINGPROCEDURES

D.TYPE“1”OPERATION

Beforeproceedingwiththistypeofoperation,attachthefirstexternal

temperature probeto the underside of the PCB to be worked on. The

secondprobecanbeplacednearareasofinterest.

Thistypeofoperationutilizesthefirstexternaltemperaturesensorto

controltheheat.Usingthistypeofoperationallowsustocloselycontrol

the temperature at board level. While freeing up the second external

temperatureprobeforadditionalmonitoring.

1. To set the desired temperature press the selection button

repeatedlyuntilthetop displayshows“Set”.Thebottomdisplay

wouldshowthecurrentsettemperaturefollowedbyasuffix“A”.

2. Press the increase or decrease button to adjust the set

temperature level. The set temperature is adjustable from 50 to

280Cinthistypeofoperation.

3. For this type of operation we must closely monitor the actual

temperatureof the first externaltemperature probe. To view the

actual temperature readout of this probe repeatedly press the

selectionbuttonuntilthetopdisplayshowstheword“Act1”,and

thebottomdisplayshowstheactualtemperatureoffirst external

temperatureprobefollowedbyasuffix“b”.

4. To view the temperature of the second external temperature

probe or simultaneously view both external temperature probe's

temperature:

●Repeatedlypresstheselectionbuttonuntilthetopdisplayshows

“Act 2” and bottom’s suffix shows “c” this displays the second

temperatureprobe.

●Repeatedlypresstheselectionbuttonuntilthetopshowsthefirst

temperature probe with suffix “b” and the bottom shows the

secondtemperatureprobewithsuffix“c”.

5. Undertype“1” mode of operation it is not necessary to monitor

theinternaltemperaturesensor’sreadout.