3.

TECHNICAL DATA

Operation mode (set from the keyboard)............ input (measurement) or output (simulation)

Universal input/output (programmable with the parameter 0:StYP), measurement and settings range:

RTD : - Pt100 (3- or 2-wire)....-100 ÷ 850 °C (factory setting of the sensor)

- Ni100 (3- or 2-wire)..... -50 ÷ 170 °C

-

Pt100, Ni100, for measurements, automatic detection of a 2- or 3-wire connection of the

sensor with line resistance compensation, automatic for 3-wire version, constant for 2-wire

version (parameter 1:rrtd)

Thermocouple:

- thermocouple J ............................ -40 ÷ 800 °C

- thermocouple K ........................... -40 ÷ 1200 °C

- thermocouple S ........................... -40 ÷ 1600 °C

- thermocouple B ........................... 300 ÷ 1800 °C

- thermocouple R ........................... -40 ÷ 1600 °C

- thermocouple T ........................... -25 ÷ 350 °C

- thermocouple E ........................... -50 ÷ 750 °C

- thermocouple N ........................... -80 ÷ 1300 °C

-

compensation of cold thermocouple end temperature, automatic or constant

(programmable with parameters 2: 2: cJtY and 3: cJtE, see chapter 6, Table 1)

Line: - voltage ............................................... -5 ÷ 55 mV

- resistance ......................................... .10 ÷ 540 Ω(measurement)

0 ÷ 1,000/Ip [Ω]≤3,200 Ω(setting)

Ip - output polarizing current [mA]

Leads resistance for RTD ................................. Rd < 25 Ω(for each line)

Resistance input current (RTD, Ω).................... ~250 µA (for measurements)

Output polarizing current Ip RTD, Ω.................100 ÷ 1,900 µA (input current in resistance simulations) (1)

Basic processing error (at ambient temperature equal to 25 °C)

- measurement: - Pt100, -5÷55 mV, 10÷540 Ω.......≤0.2% of sensor range ±1 digit

- Ni100, all thermocouples………...≤0.3% of sensor range ±1 digit

- setting (simulation):- Pt100, Ni100....................… ≤2 °C for Ip > 200 µA and ≤3 °C for Ip < 200 µA

- J, K, E, N, 55 mV, 0÷3.2 kΩ.......… ≤0.2% for sensor range and ≤1.5 Ωfor 0÷3.2 kΩ

- S, B, R, T...................................….≤0.3% of sensor range

Additional error for setting Pt100,Ni100, 0÷3,2kΩ… ≤2,5°C or ≤1Ω(nonlinearity)

Additional error for thermocouple inputs ...........….≤2 °C (present only in automatic compensation

of cold tip temperature)

Additional error from temperature changes........….≤0.01% of the sensor range/°C

Resolution of indications.....................................… 0.1 °C or 1 °C (programmable with parameter 6: dot)

Resolution of settings in simulations...............…… 0.5 ÷ 200.0 °C, set with parameter 9:StEP, default value 1°C

Response time for measurements (10÷90%)....…… 0.7 ÷ 2.3 s, set with parameter 5:FiLt, default value 1.3 s

LCD display (7-segment, 4 digits)

- range of indications ....................................….. -1999 ÷ 9999

- digit height .................................................….. 10 mm

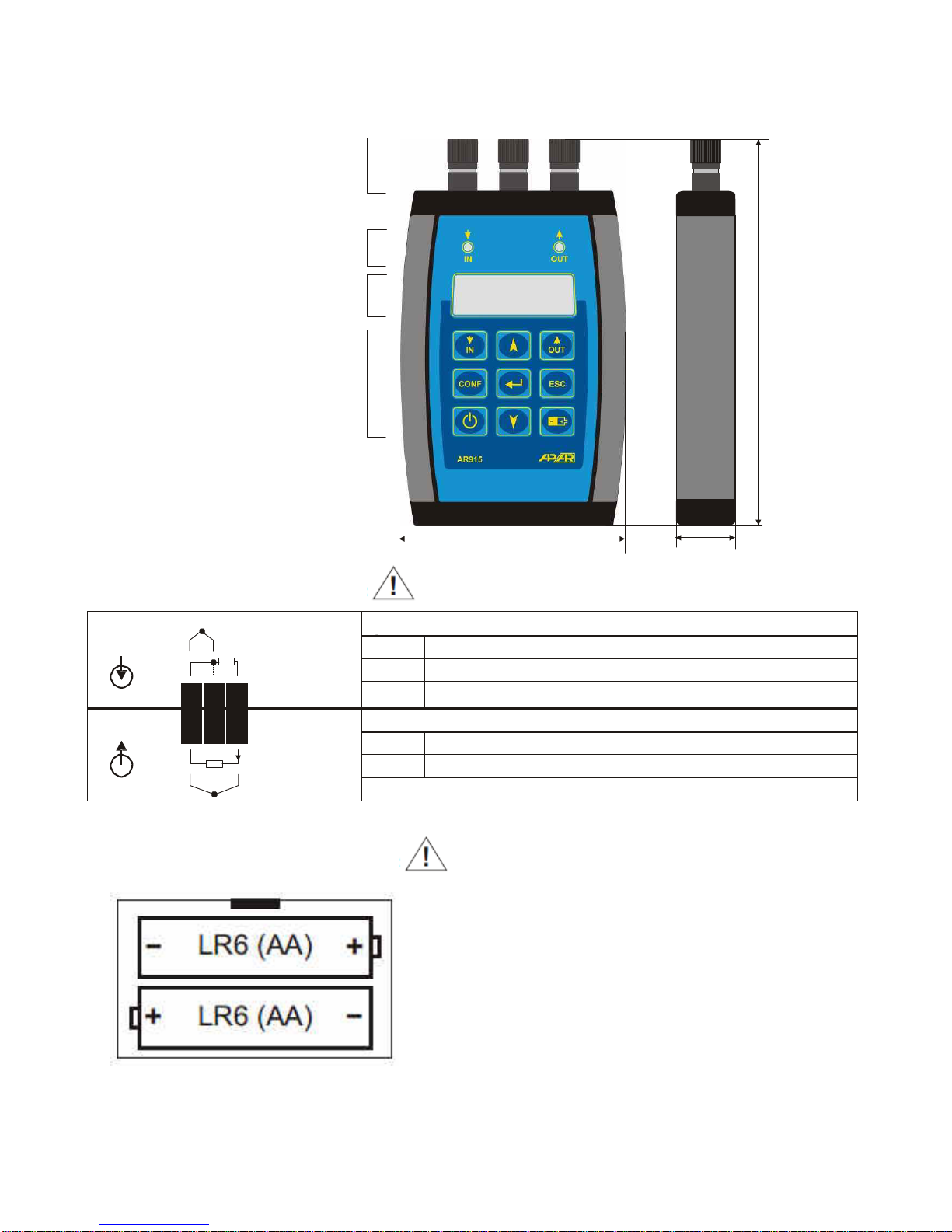

Power supply (regular or rechargeable batteries) 2 x 1.5 V (2 x 1.2 V NiMH), type AA (LR6) (2)

Operation time...................................................…..300 ÷ 400 hours(with rechargeable batteries 2 x 1.2 V/2,5 Ah)

Operating temperature range ...........................…..0 ÷ 50 °C

Relative humidity range ...................................…. 0 ÷ 90 % (no condensation)

Housing .............................................................…. manual, ABS material

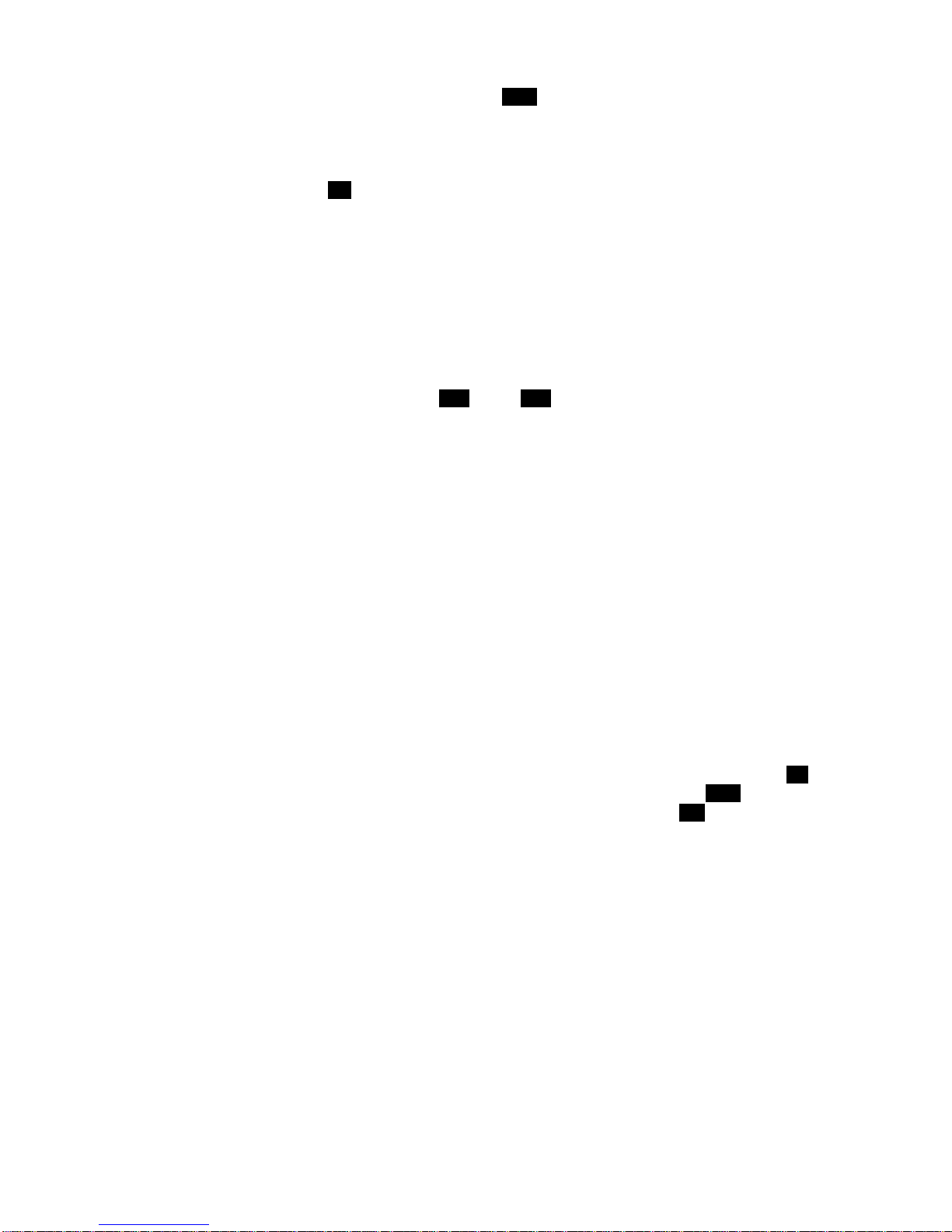

Dimensions........................................................….136 x 80 x 25 mm

Protection rating................................................… IP43

Operating position ............................................… any

Weight................................................................…~130 g (w/o batteries), ~165 g (w/ batteries)

Electromagnetic compatibility (EMC)

-

immunity: according to the PN-EN 61000-6-2:2002(U) standard

-

emissivity: according to the PN-EN 61000-6-4:2002(U) standard

(1) - simulation of resistance (RTD, Ω)does not work for multiplexed inputs (pulse IP current)

(2) - when replacing the batteries, pay attention to the polarity shown in the battery compartment