Note: The remote vent v lve m y be ddition lly inst lled between the integrity test instrument

nd the P lltronic Flow Check II unit (or between the integrity test instrument nd the upstre m

volume, if required) so th t le ks within the remote v lve m y be detected. Therefore, should

the Flow Check test f il, ple se repe t the Flow Check test without the remote vent v lve

tt ched to determine whether the remote vent v lve is the c use of the f ilure or not.

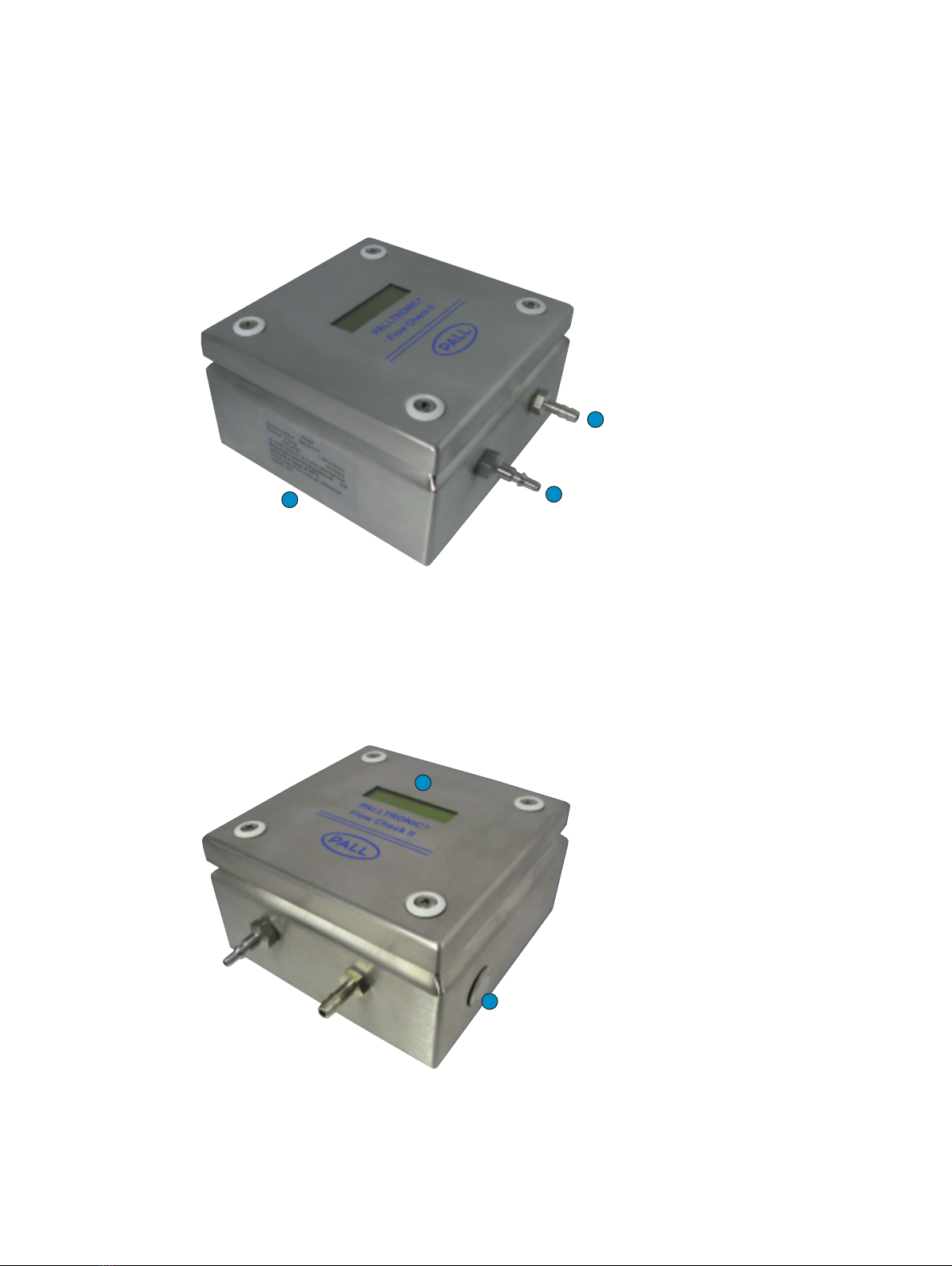

• Ensure that the ‘VENT’ connection on the Palltronic Flow Check II unit is open to atmosphere.

• It is recommended that the red pneumatic tubing supplied with the Palltronic Flow Check II

unit be used exclusively for this purpose. It is also highly recommended that this tubing is

kept clean and dry. In this way accidental contamination of the internal capillary within the unit

can be mitigated.

Import nt: Although the P lltronic Flow Check II unit h s n integr l G skleen filter in order to

limit the possibility of cont min ting the intern l c pill ry, the oper tor should still t ke gre t

c re to void cont min tion. Should either the integr l filter or the c pill ry become

cont min ted, d m ged or blocked, the oper tion of the P lltronic Flow Check II unit will be

severely compromised.

3.4 Performing a ‘Flow Check’ Test

Note: The following test procedure ssumes th t the integrity test instrument provides

dedic ted ‘Flow Check’ test (see your integrity test instrument Oper ting Instructions for the

instrument c p bilities). If the dedic ted ‘Flow Check’ test is not v il ble, ‘Forw rd Flow’ test

m y be used inste d. In this situ tion, the ‘Expected Flow’ becomes the ‘M ximum Flow’ test

p r meter nd the p ss/f il result t the end of the test should be ignored: refer inste d to

Section 3.5 for the interpret tion of the result.

• Select a ‘Flow Check’ test on the Palltronic integrity test instrument (for more information, see

the relevant Operating Instructions for your integrity test instrument).

• Enter the following test parameters (and where indicated by 1below, using the relevant values

displayed by the Palltronic Flow Check II unit in use, see also Section 3.2.

Test Pressure1: 2000 mbar (29 psi)

Test Time: 600 seconds

Ref. Unit Serial No.1: 1234567

Expected Flow:1X.XX m /min

• Press the ‘Start’ button on the Palltronic integrity test instrument to activate the

‘Flow Check’ test.

• On completion of the test (i.e. after the test time has elapsed), the measured value will be

given with a percent deviation value between the measured and the expected values (if the

dedicated ‘Flow Check’ test has been used).

Note: After use, the P lltronic Flow Check II unit should be c refully disconnected from the

P lltronic integrity test instrument, the protective c ps should be repl ced on the inlet nd vent

ports nd the unit stored in dry pl ce t room temper ture.

3.5 Understanding the Test Results

The test result will be reported as a flow rate value. Under stable test conditions, the Palltronic

integrity test instrument should be within ± 5% of the expected flow value displayed by the

Flow Check II unit.

The expected flow value is calculated from the reference value (as shown on the side of the

Palltronic Flow Check II unit and on the calibration certificate provided with the Palltronic Flow

Check II unit) by compensating for any variation in atmospheric pressure.

If the dedicated ‘Flow Check’ test has been used, the percent deviation value will be calculated

and presented by the integrity test instrument. If, however, the integrity test instrument does not

www.pall.com/b opharm 7