2

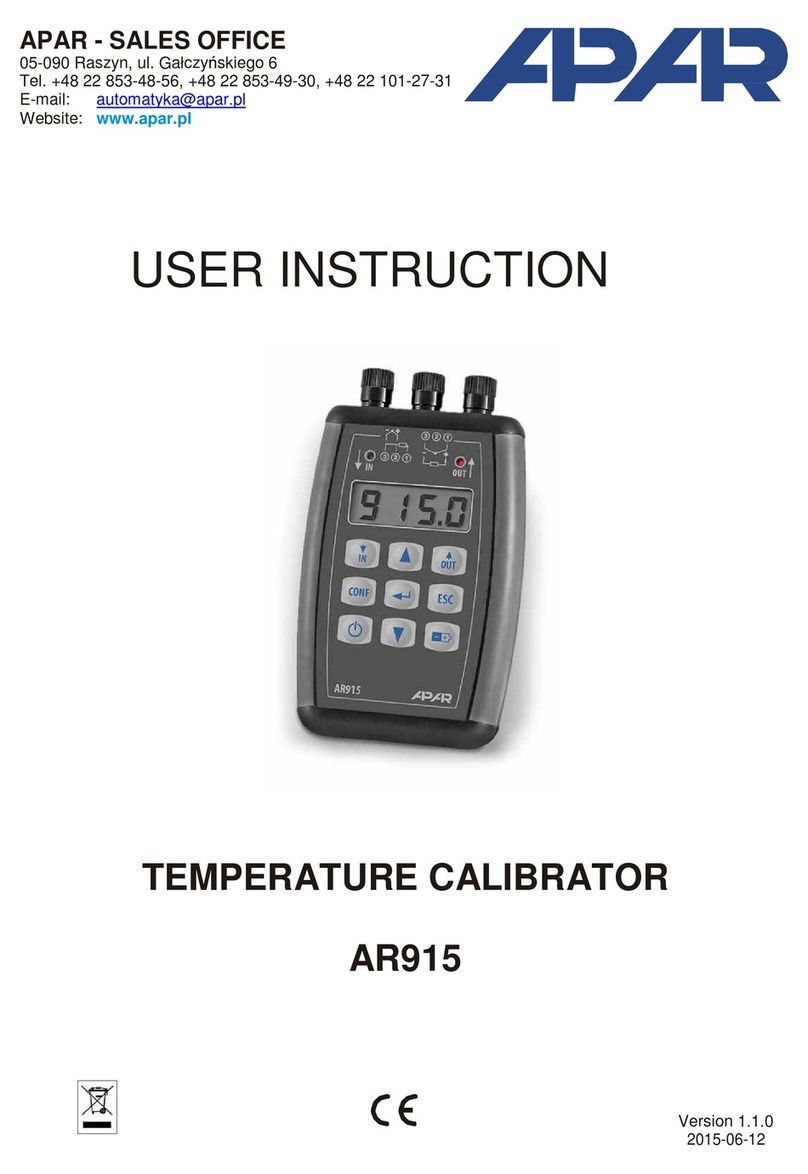

Thank you for choosing our products.

This manual will aid you with a correct and safe

use and full utilisation of the programming device.

Before installation and use

please read and understand this manual.

If you have any further questions, please contact your technical advisor.

TABLE OF CONTENTS

1. SAFETY RULES ........................................................................................................... 3

2. INSTALLATION GUIDELINES ...................................................................................... 3

3. GENERAL CHARACTERISTICS OF THE PROGRAMMING DEVICE.................................. 3

4. CONTENTS OF THE KIT.............................................................................................. 4

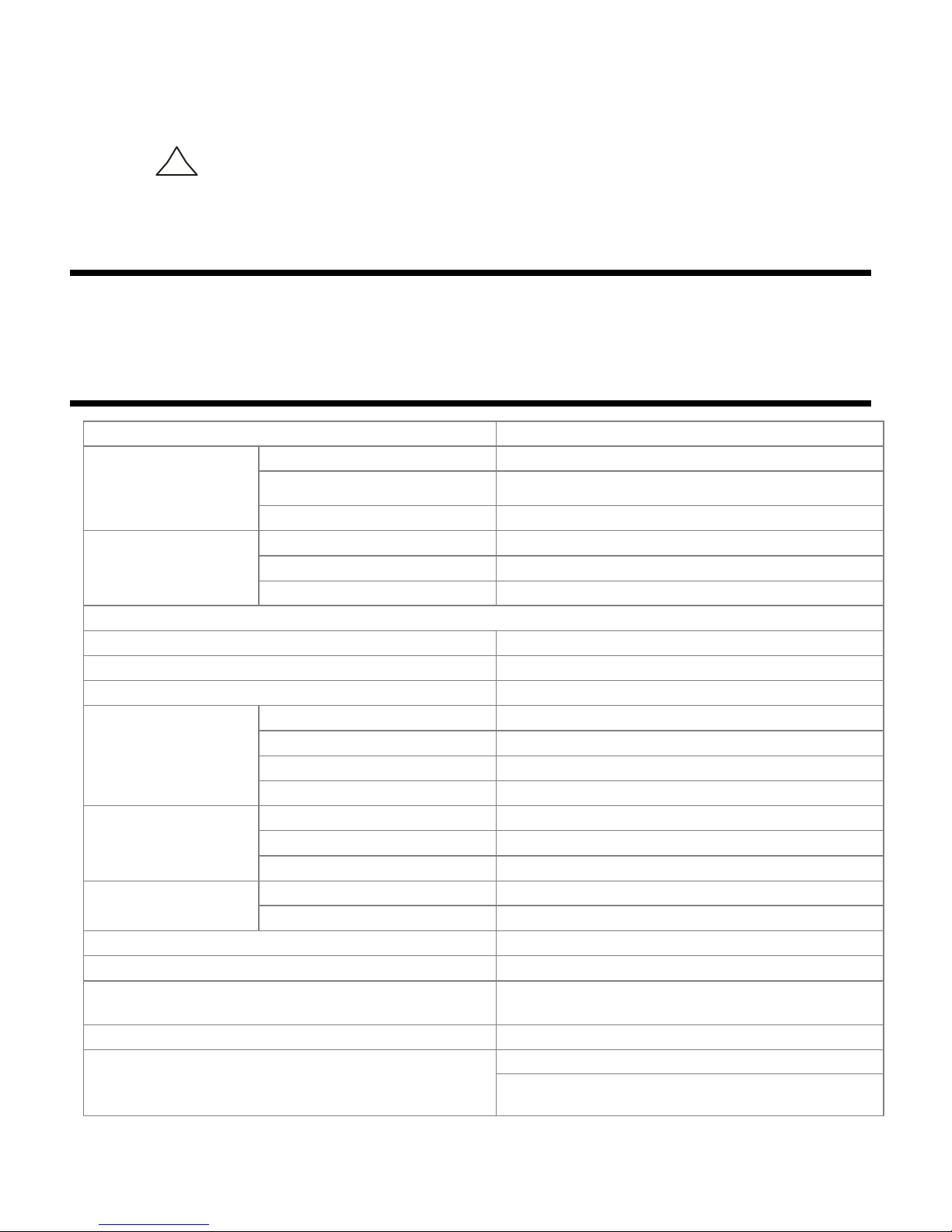

5. TECHNICAL SPECIFICATIONS ..................................................................................... 4

6. ENCLOSURE MEASUREMENTS AND INSTALLATION DATA .......................................... 5

7. DESCRIPTION OF TERMINALS AND ELECTRICAL CONNECTIONS ................................ 5

8. ENCLOSURE MEASUREMENTS AND INSTALLATION DATA .......................................... 5

9. CHANGING THE OUTPUT SETPOINT .......................................................................... 6

10. SETTING CONFIGURATION PARAMETERS ................................................................ 7

11. SOFT START/STOP AND TRIANGLE WAVE GENERATOR .......................................... 9

12. MESSAGES AND ERRORS ........................................................................................ 10

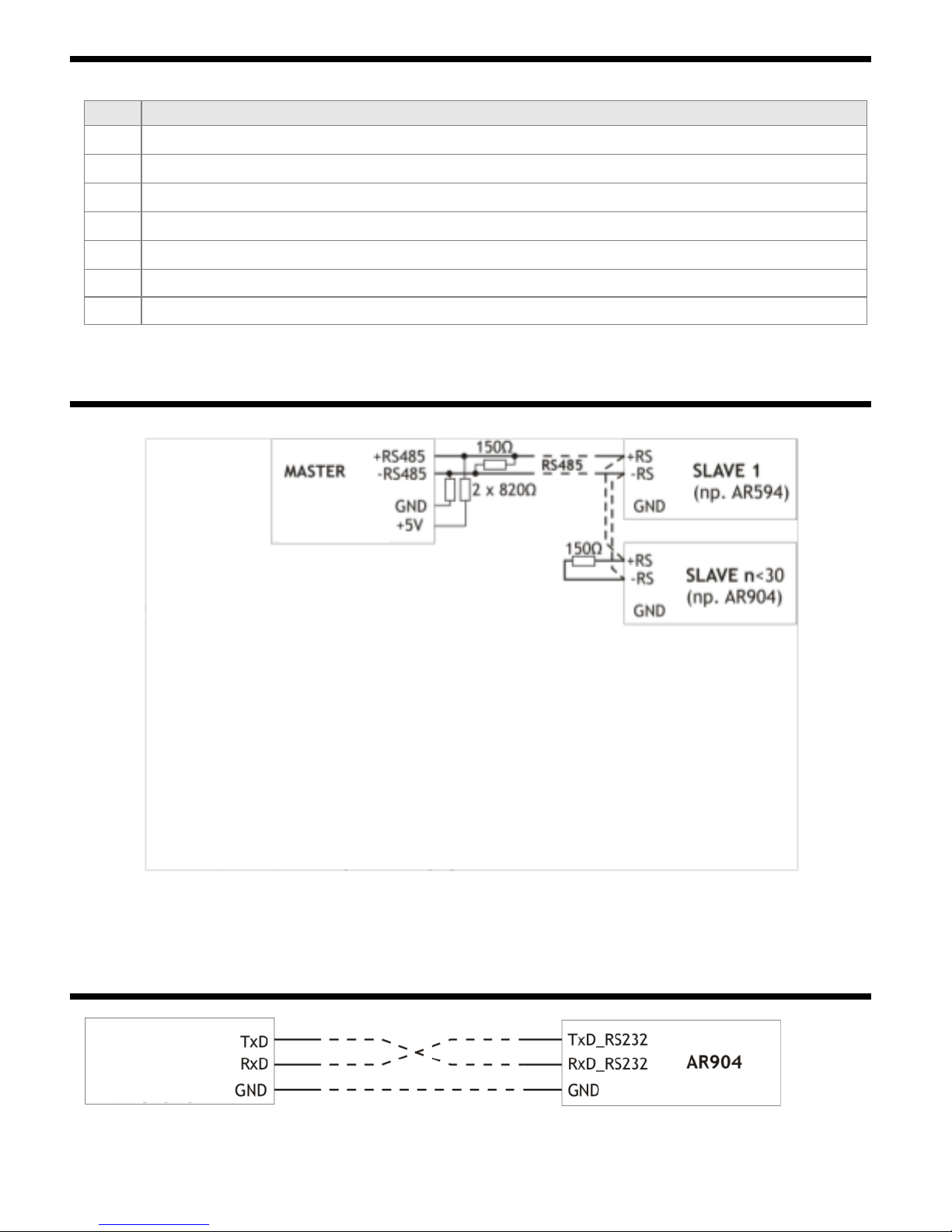

13. COMMUNICATION INTERFACE RS485 (in accordance with EIA RS-485)................ 10

14. COMMUNICATION INTERFACE RS232C (in accordance with EIA RS-232C) ........... 10

15. MODBUS - RTU SERIAL COMMUNICATION PROTOCOL........................................... 11

16. NOTES.................................................................................................................... 12

Particular attention shall be paid to the texts bearing this symbol

The manufacturer reserves the right to make changes in the design and software of the device without decreasing its technical parameters.