OPERATION / MAINTENANCE MANUAL

7032SOUTH196th-KENT,WA.98032-(253)872-0141/FAX(253)872-8710

MODEL475POWERUNIT

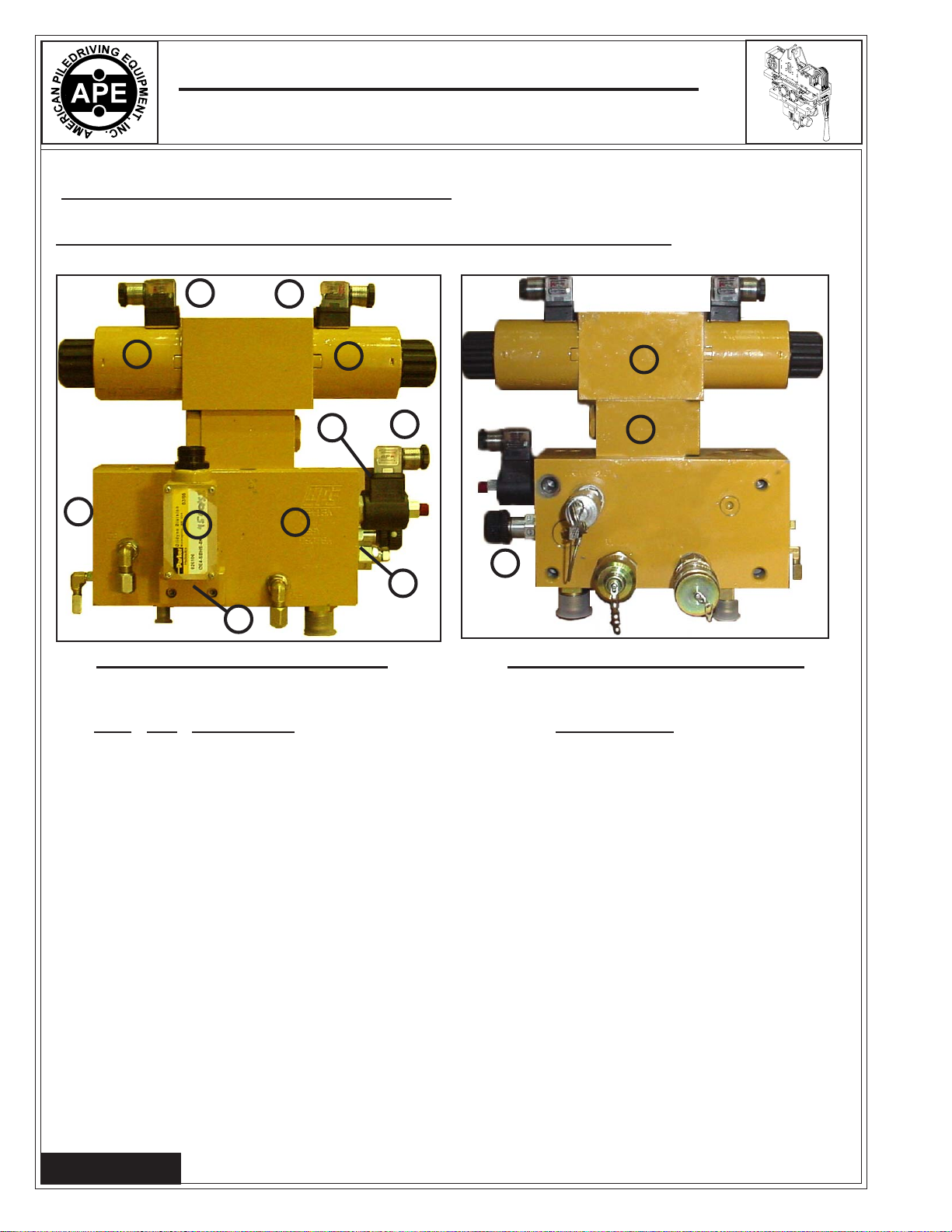

VII. MODEL 475 POWER UNIT

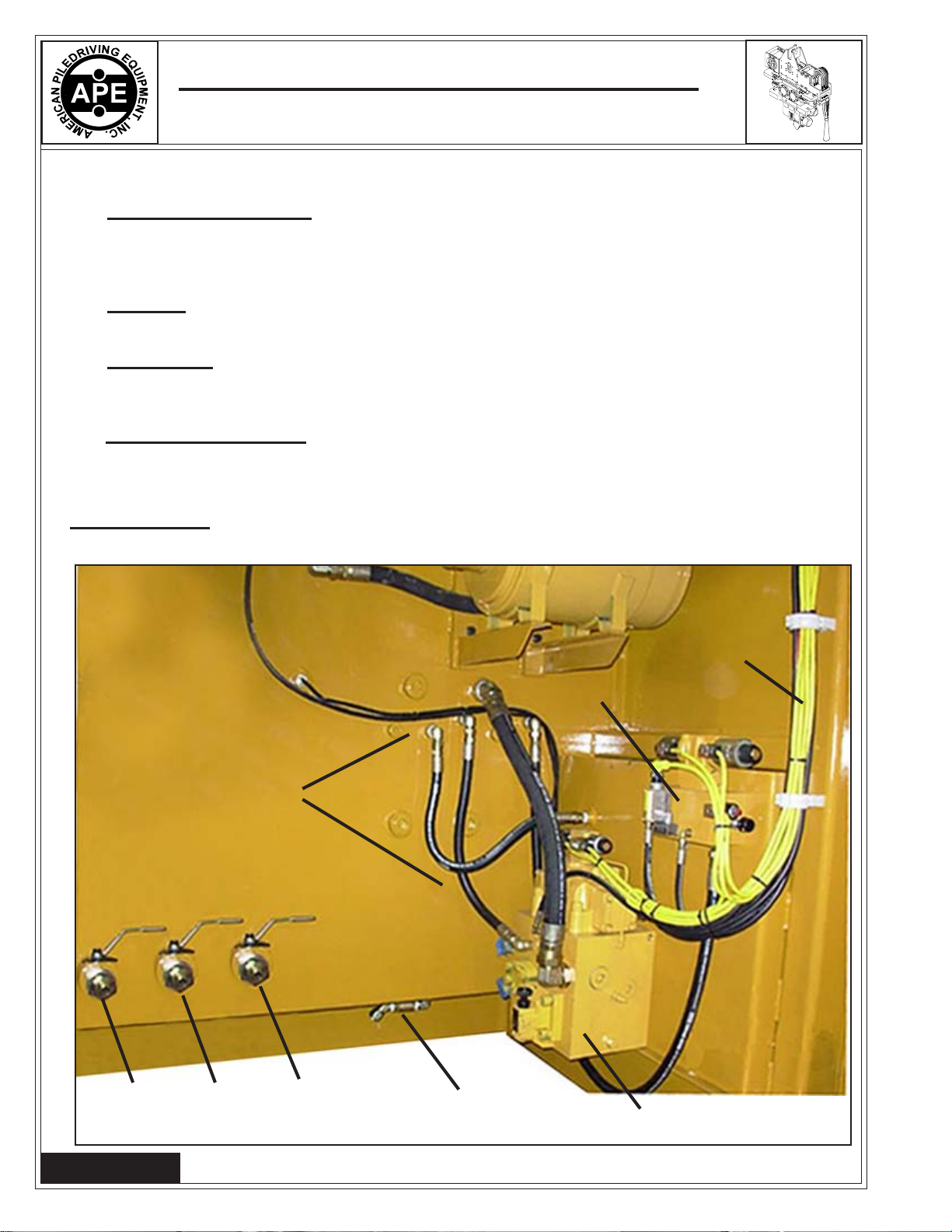

VII-1.HydraulicCircuitry.

ThefollowingaredescriptionsofthecomponentsthatmakeuptheHydraulicCircuitryoftheAPEModel

475powerunit.

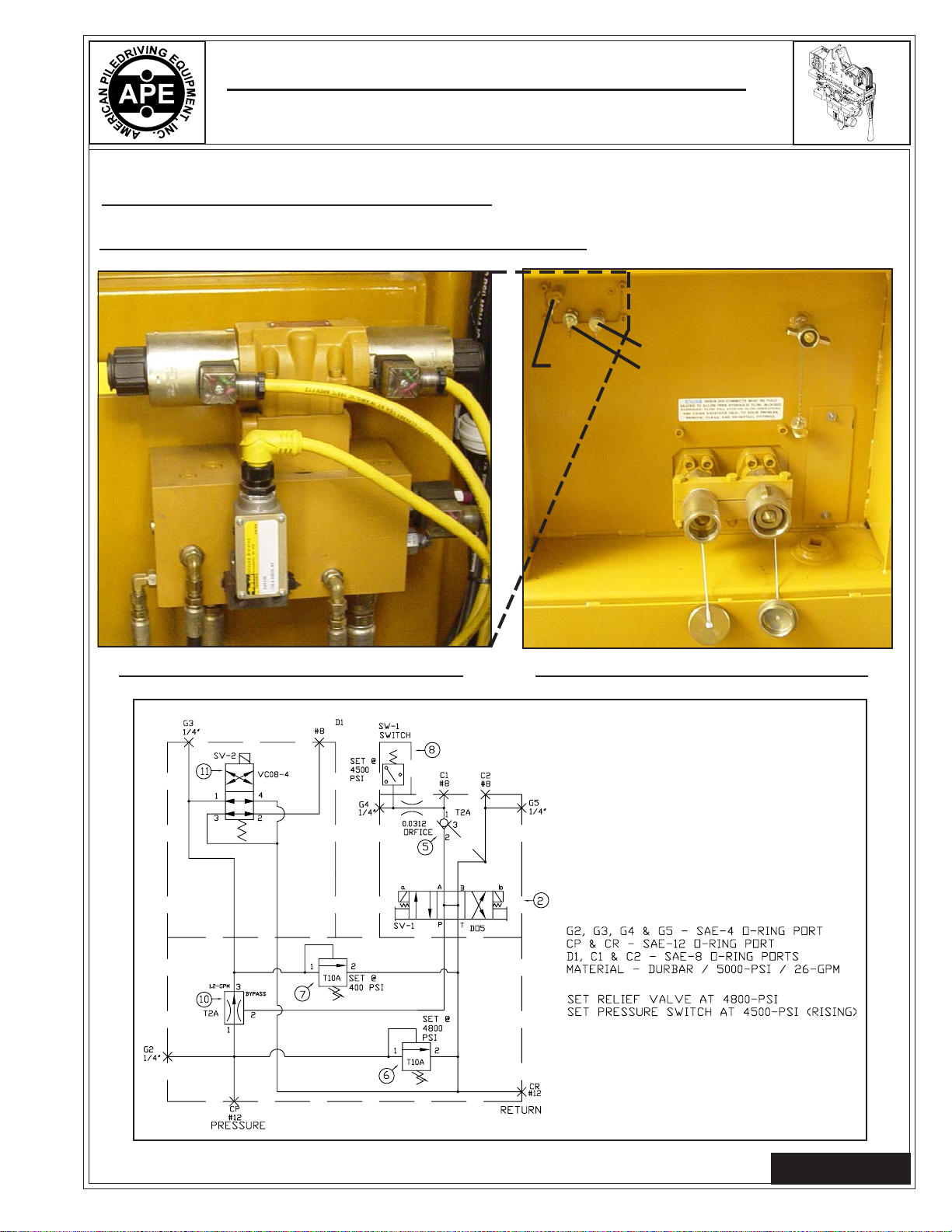

VII-1A.ClampCircuitry.(Usedforextendingandretractingjawcylinder)

Oilfortheclampcircuitisprovidedbyitemtheclamppump.Thispumpisal.5cu.in/rev5000psipiston

pump. Alloiltotheinletofthispumpisfilteredthroughasuctionstrainerlocatedinthetank. Clampoil

isthendirectedfromthepumptotheclampdirectionalcontrolvalve. Whentheclampswitchisinthe

"off"position,theoilflowsthoughttheclampdirectionalcontrolvalveandbacktotheoiltank. When

theclampswitchismovedtoopen,solenoid"A"ontheclampdirectionalcontrolvalveisenergizedthe

oilwillflowouttotheclampcylinderandretractoropenthejaws. Theclampopenpressurecanbeseen

on the clamp pressure gage located on the panel. When the clamp switch is moved to the closed

position,solenoid"B" willbeenergizedand oilflowwillbe directedtotheclamp cylinder. Theclamp

cylinderwillthenextendorclosethejaws. AClamppressure switchitemwillde-energizesolenoid"B",

directing pump oil flow back to oil tank. Clamp pressure is maintained in clamp cylinder by a pilot

operatedcheckvalve.Atanytimeshouldtheclamppressurefallbelow3500psi.theclamppressure

switch will re-energize solenoid "B" on the clamp control valve, and direct pump flow to the clamp

cylinder.Maximumclamp pressureislimitedby theclamppressurerelief valvesetat4300 psi. The

quickdisconnectcouplerspermitdecouplingofclamphoses.

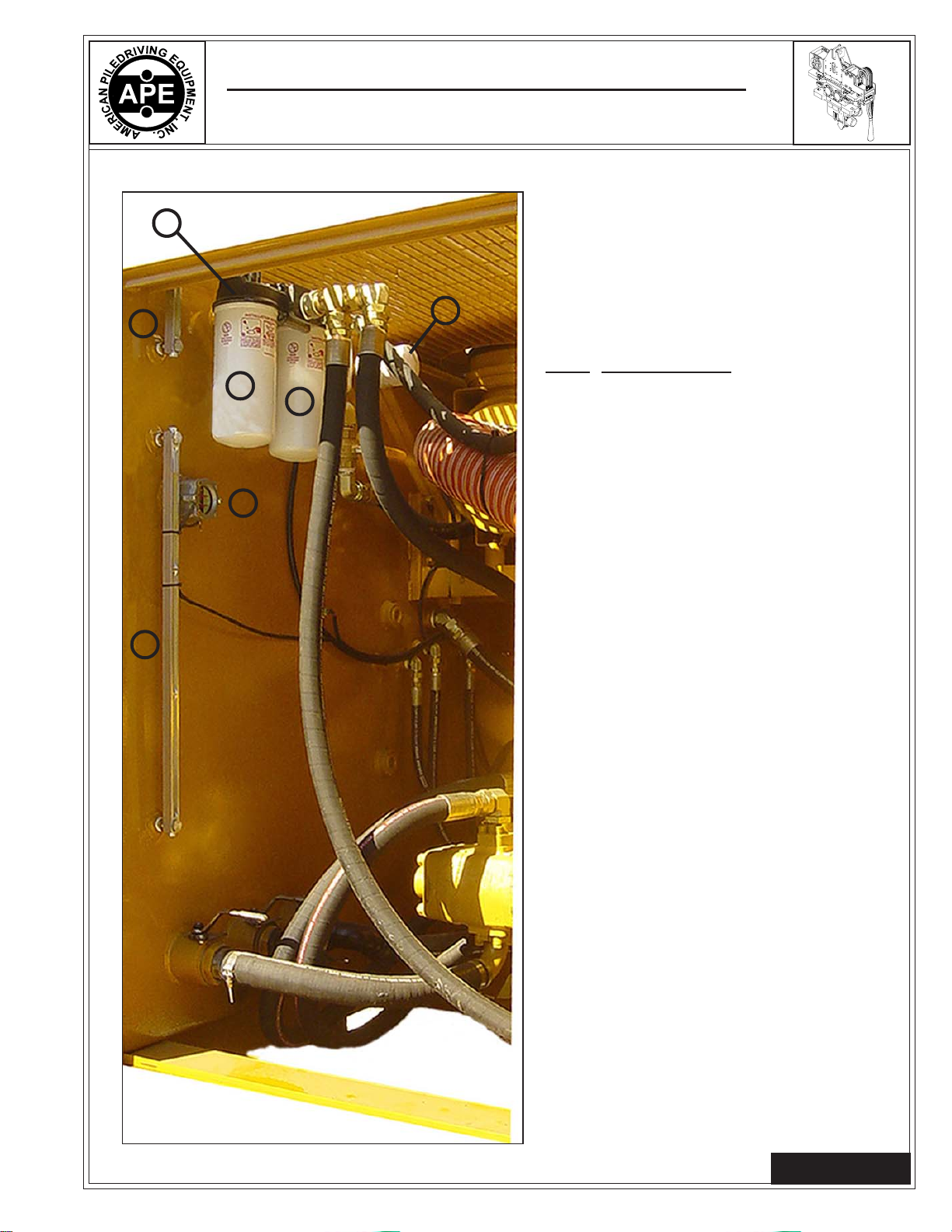

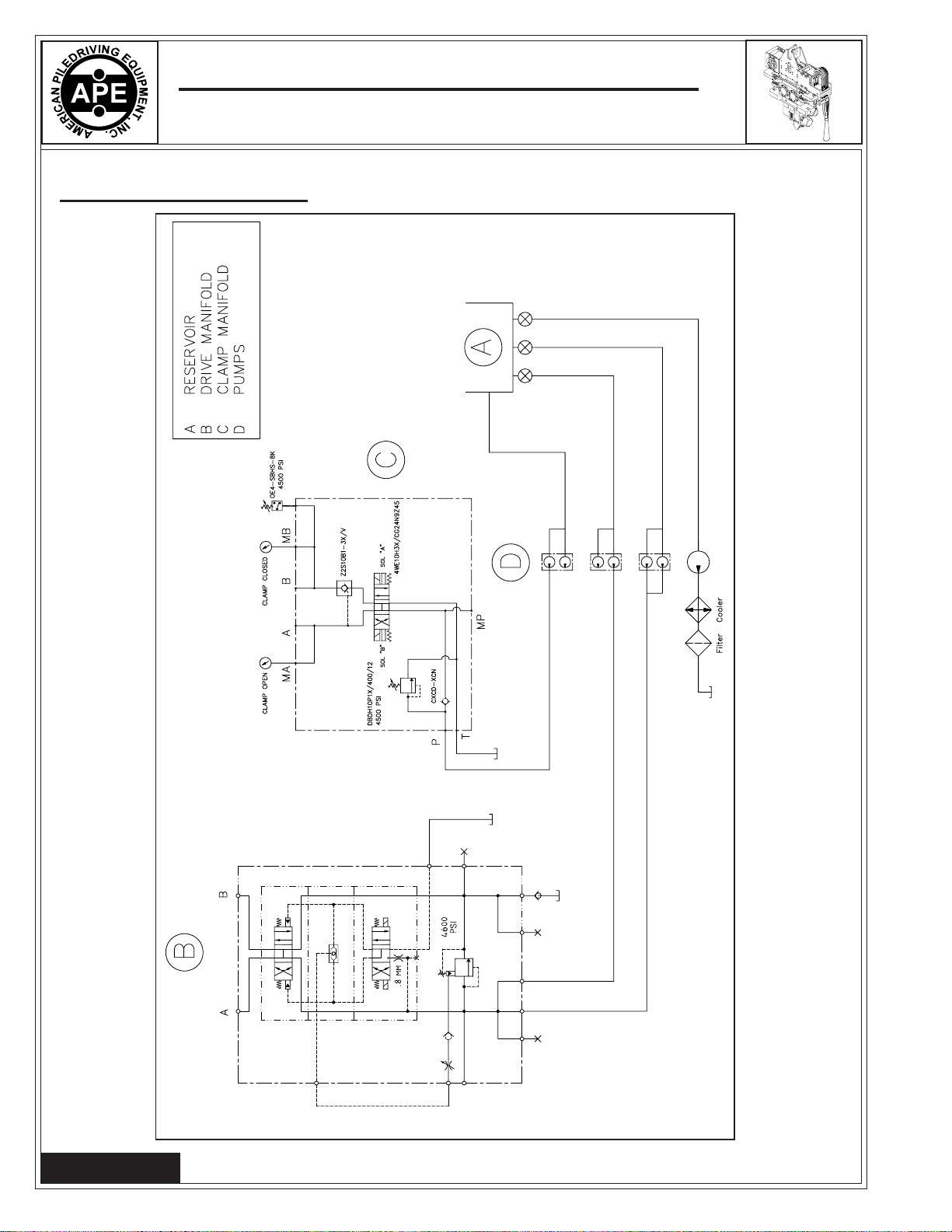

VII-1B. Drive Circuit. (UsedforoperatingAPEvibrator,APE drill or any otherunit)

Therearetwogearpumpsthatdirectoiltothedrivecircuit(VibroMotors).Themaximumdrivepressure

iscontrolledbythedrivepressurereliefvalve,to4800psi.max.Whenthedriveswitchismovedtothe

forwardposition,solenoid"A"ofthedrivedirectionalcontrolvalveisenergized.Oilflowisdirectedto

thevibromotorstorotatetheeccentrics.Whenthedriveswitchismovedtotheoffposition,oilflowis

directedbacktothetankthroughthedrivedirectionalcontrolvalveandsolenoid"A"isde-energized.

Becauseofthehighoilflowinthedrivecircuit,APE,Inc.hasdevelopedacircuitthateliminateshigh

shockloads. Smallinternalcomponentslocatedinthedrivemanifoldprovideasoftshiftfeatureforthe

drivedirectionalcontrolvalve. A smalladjustablesnubbervalvecontrolsasmallshuttlevalvethrough

smallfixedorifices. Theorificesareusedtodampentheshiftingof spoolvalve. Thisprovides asoft

start/stopofthedrivedirectionalcontrolvalvepreventinghydraulicshocktothedrivesystem. Theshuttle

valveisusedtosendahydraulicsignaltothedrivepressurereliefvalvewhenthedrivedirectionalcontrol

valveiscenteredorde-energized.Thishydraulicsignaltellsthedrivepressurecontrolvalvetoopenand

allowanyhighflow,highpressurebacktotank. Thesnubbervalvesimplycontrolshowfastthissignal

isreceivedbythedrivepressurereliefvalve.Thedrivepressurecanbereadonthedrivepressuregage

item.

Thequick-disconnectcouplings permitde-couplingofthedriveandcasedrainhosesatthepowerunit.

Page 7-1

Page 7-1

Copyright © 2023 American Piledriving Equipment, Inc. All Rights Reserved