Table of Contents

1Overview..............................................................................................................................- 3 -

1.1 Luminescent optical sensor. ..........................................................................................- 3 -

1.2 Intelligent Instrumentation..............................................................................................- 3 -

2Technical Specifications .......................................................................................................- 4 -

3Instructions ..........................................................................................................................- 5 -

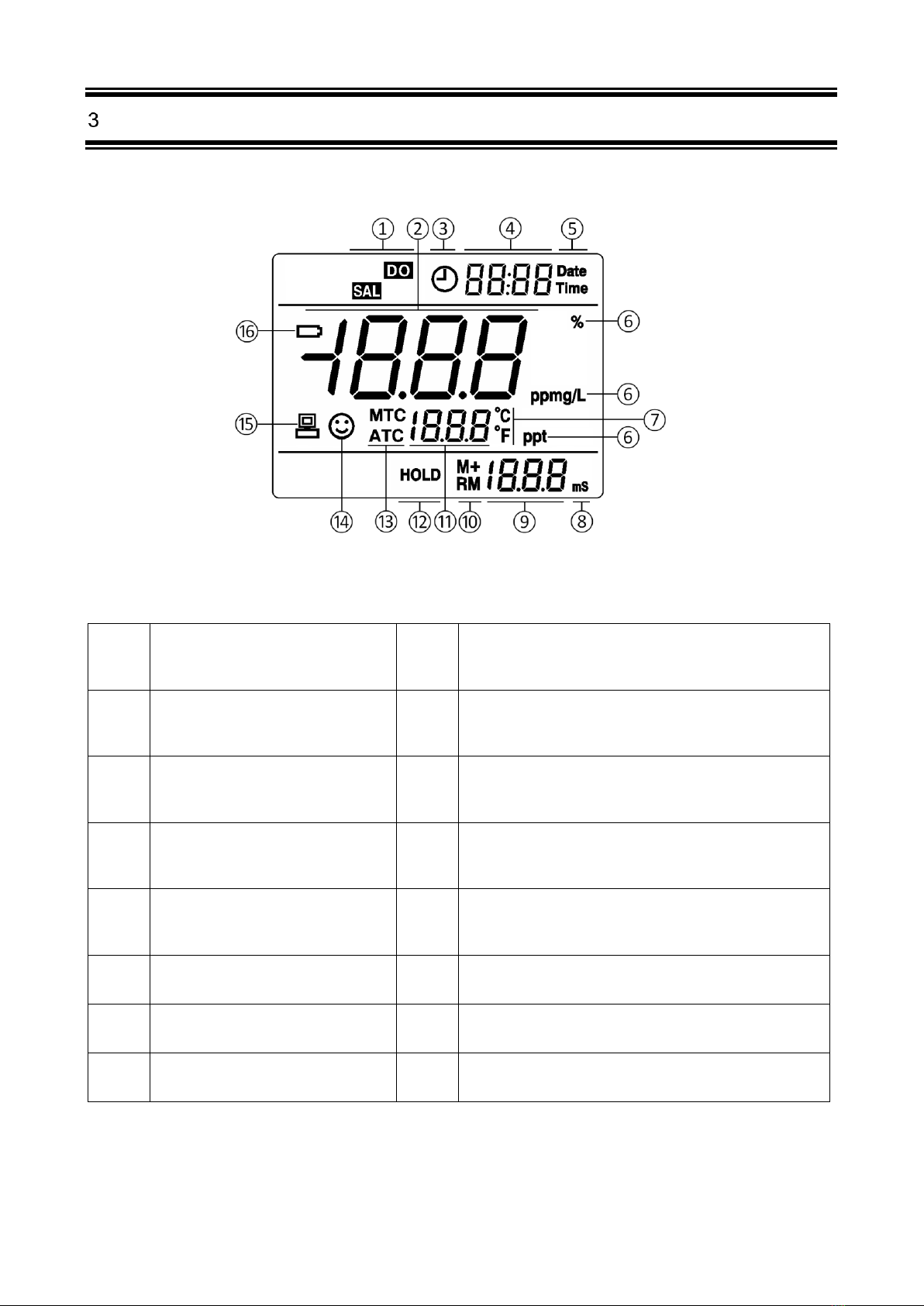

3.1 LCD Screen...................................................................................................................- 5 -

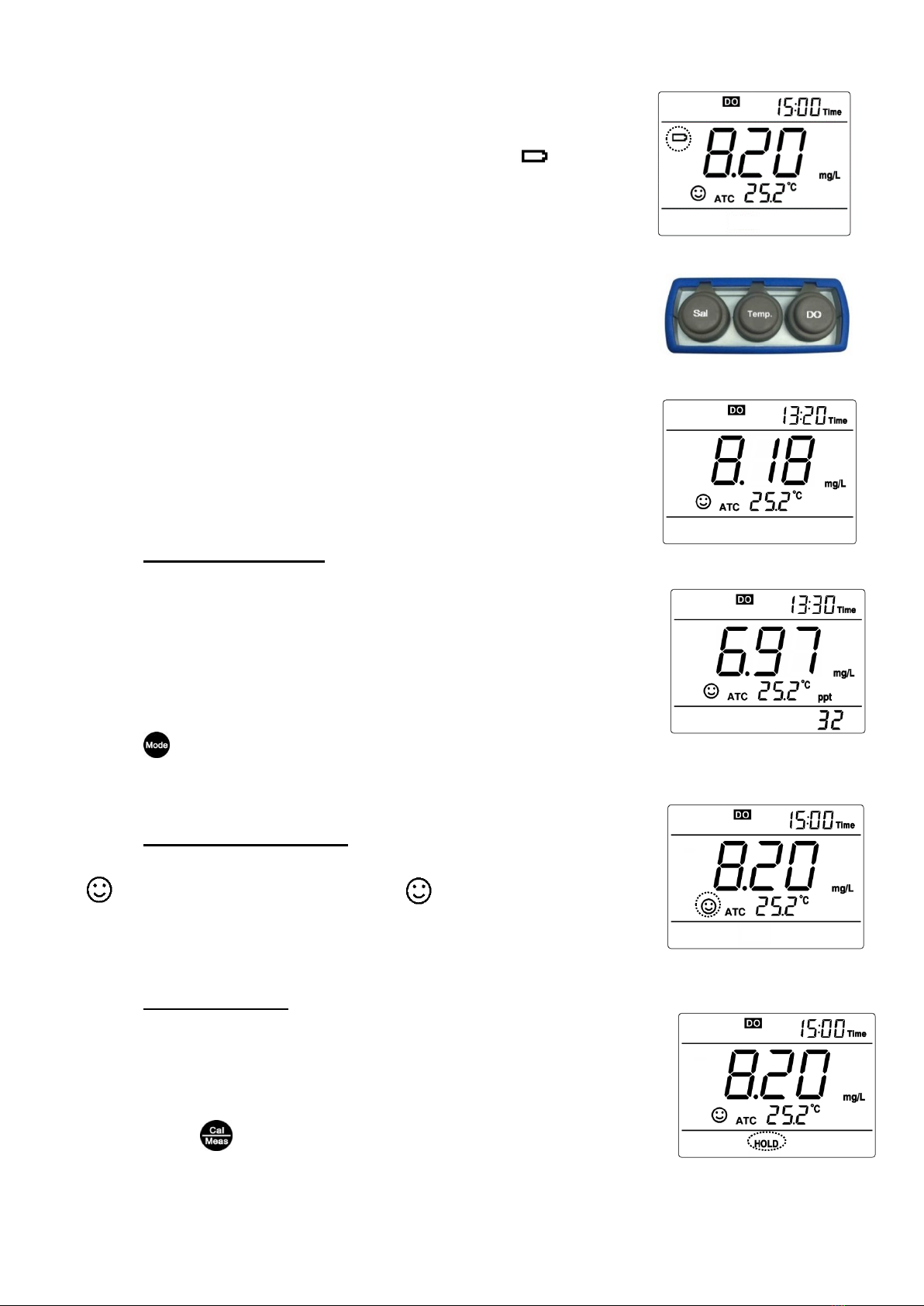

3.2 Key Operation ...............................................................................................................- 6 -

3.3 Batteries ........................................................................................................................- 7 -

3.4 Instrument Socket .........................................................................................................- 7 -

3.5 Display mode.................................................................................................................- 7 -

3.6 Data storage, recall, and clear. ......................................................................................- 8 -

3.7 Backlighting ...................................................................................................................- 8 -

3.8 Automatic Power-Off .....................................................................................................- 8 -

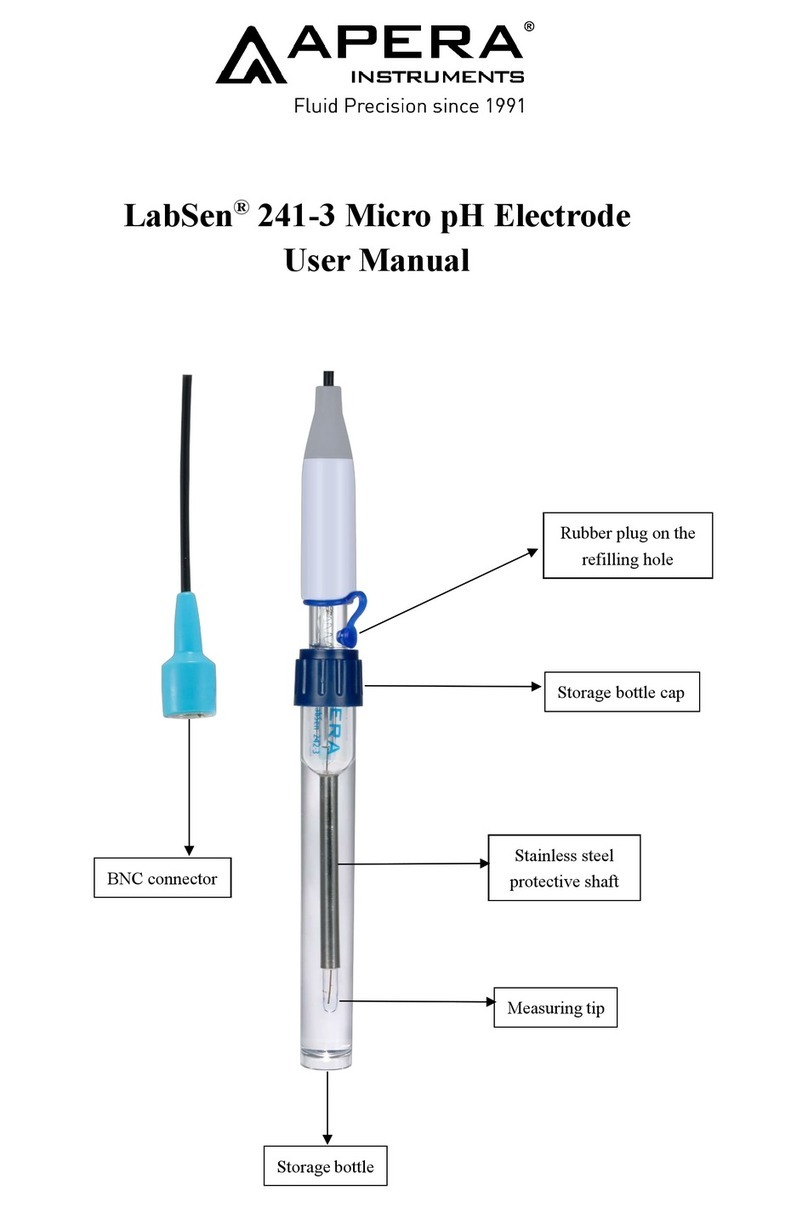

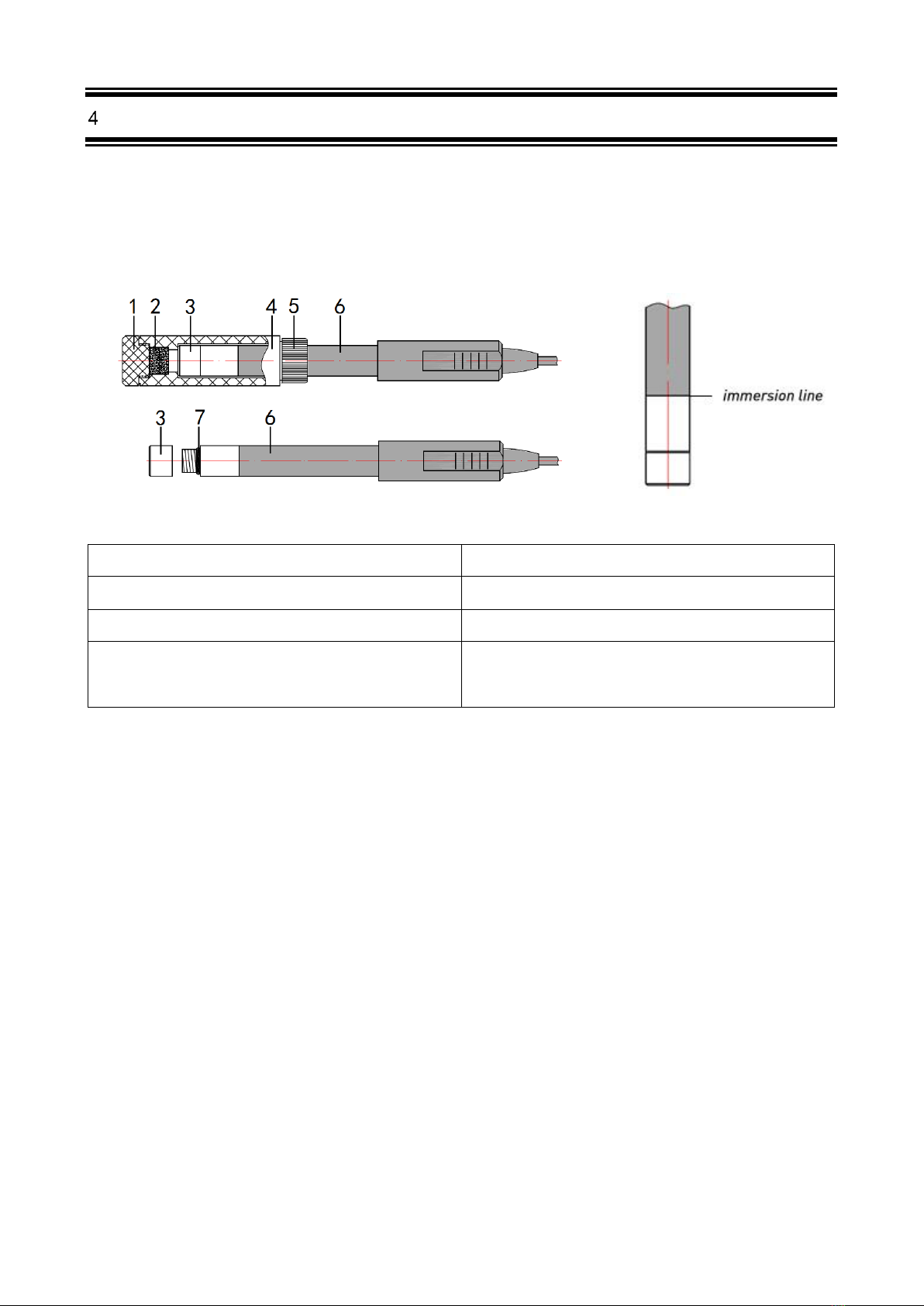

4Optical Dissolved Oxygen Probe..........................................................................................- 9 -

4.1 Probe Structure .............................................................................................................- 9 -

4.2 Probe Maintenance .......................................................................................................- 9 -

4.3 Sensor Cap .................................................................................................................- 10 -

5Preparation for Calibration .................................................................................................- 10 -

5.1 Dissolved Oxygen Units Selection...............................................................................- 10 -

5.2 Resolution Selection....................................................................................................- 11 -

5.3 Temperature Unit Selection .........................................................................................- 11 -

5.4 Air Pressure Compensation.........................................................................................- 11 -

5.5 Salinity Compensation.................................................................................................- 11 -

6Calibration..........................................................................................................................- 12 -

6.1 Saturated Oxygen Calibration......................................................................................- 12 -

6.2 Zero-Oxygen Calibration .............................................................................................- 12 -

6.3 Special Notes for Calibration .......................................................................................- 13 -

7Measurement .....................................................................................................................- 13 -

8Parameter Settings ............................................................................................................- 14 -

9USB Communication..........................................................................................................- 17 -

10 Complete Kit ......................................................................................................................- 19 -

10.1 What’s in the box.........................................................................................................- 19 -

10.2 Accessories for separate purchase..............................................................................- 19 -

11 Warranty...............................................................................................................................- 20 -

12 Trouble Shooting..................................................................................................................- 21 -

11 Appendix A: Oxygen Solubility Table (760mm Hg)..............................................................- 22 -

12 Appendix B: DO % Calibration Values................................................................................- 23 -