Apex Digital Cleco mPro4000GC User manual

For additional product information visit our website at www.ClecoTools.com

Installation Instructions

P2434JH

2019-08

mPro400GC(D)

Integrating mPro400GC and mPro400GCD

P2434JH | 2019-08 Apex Tool Group

Copyright © Apex Tool Group, 2019

No part of this document may be reproduced in any way or in any form, in whole or in part, or in a natural or

machine-readable language, or transmitted on electronic, mechanical, optical, or other media, without the

express permission of the Apex Tool Group.

Disclaimer

Apex Tool Group reserves the right to modify, supplement, or improve this document or the product without

prior notice.

Trademark

Cleco is a registered trademark of Apex Brands, Inc.

Apex Tool Group GmbH

Industriestraße 1

73463 Westhausen

Germany

Apex Tool Group P2434JH | 2019-08 3

EN

Contents

1 About this Document ............................................................................ 4

2 Distinction of Global Controller types ................................................... 5

3 mPro400GC replaced by mPro400GCD .............................................. 6

3.1 Primary/Master controller ............................................................................................ 6

3.2 Primary/Master controller with existing Secondary controllers.................................... 7

3.3 Primary/Master controller with new Secondary controllers.......................................... 9

3.4 Install Primary/Master controller with Secondary controllers mPro400GC................ 11

3.5 Install Primary/Master controller with Secondary controllers mPro400GCD ............. 11

3.6 Primary/Master controller with two types of Secondary controllers........................... 13

3.7 Primary/Master controller with Secondary controllers and Stack Lights.................... 15

3.7.1 mPro400GC .............................................................................................................. 15

3.7.2 mPro400GCD............................................................................................................ 17

About this Document

4 P2434JH | 2019-08 Apex Tool Group

1

EN 1About this Document

The original language of this document is English.

This document is intended for all persons who replaces mPro400GC-P/-M by mPro400GCD-P/-M.

This document has the following purposes:

• It provides important instructions for safe and effective operation.

• It describes the functions and operations of this equipment.

Other documents

Symbols in the text

Observe the safety instructions listed in the respective hardware descriptions!

Number Name

P2280PM Programming Manual mPro400GC(D)

P2300HW Hardware Description mPro400GCD-P

P2349HW Hardware Description mPro400GCD-S(H)

P2309HW Hardware Description mPro400GCD-M

P2174HW Hardware Description mPro400GC

italic Menu options (e.g., Diagnostics) input fields, check boxes, radio buttons or dropdown

menus.

> Indicates selection of a menu option from a menu, e.g., File > Print

<…> Specifies switches, pushbuttons or the keys of an external keyboard, e.g., <F5>

Courier Filenames and paths, e.g., setup.exe

• List

- List, level 2

a)

b)

Options

→ Result

1. (...)

2. (...)

Action steps

Single action step

Apex Tool Group P2434JH | 2019-08 5

Distinction of Global Controller types

2

EN

2 Distinction of Global Controller types

There are two types of Global Controller:

• mPro400GC: only for analog tools

• mPro400GCD: for analog and digital tools

The controller type can be identified on the bottom side:

• for Series on the type plate

• mPro400GCD-P controller have a second connection for „digital“ NeoTek tools

Comparison of mPro400GC and mPro400GCD

Controller Type mPro400GC mPro400GCD

Primary mPro400GC-P mPro400GCD-P

Master mPro400GC-M mPro400GCD-M

Secondary mPro400GC-S mPro400GCD-S(H)

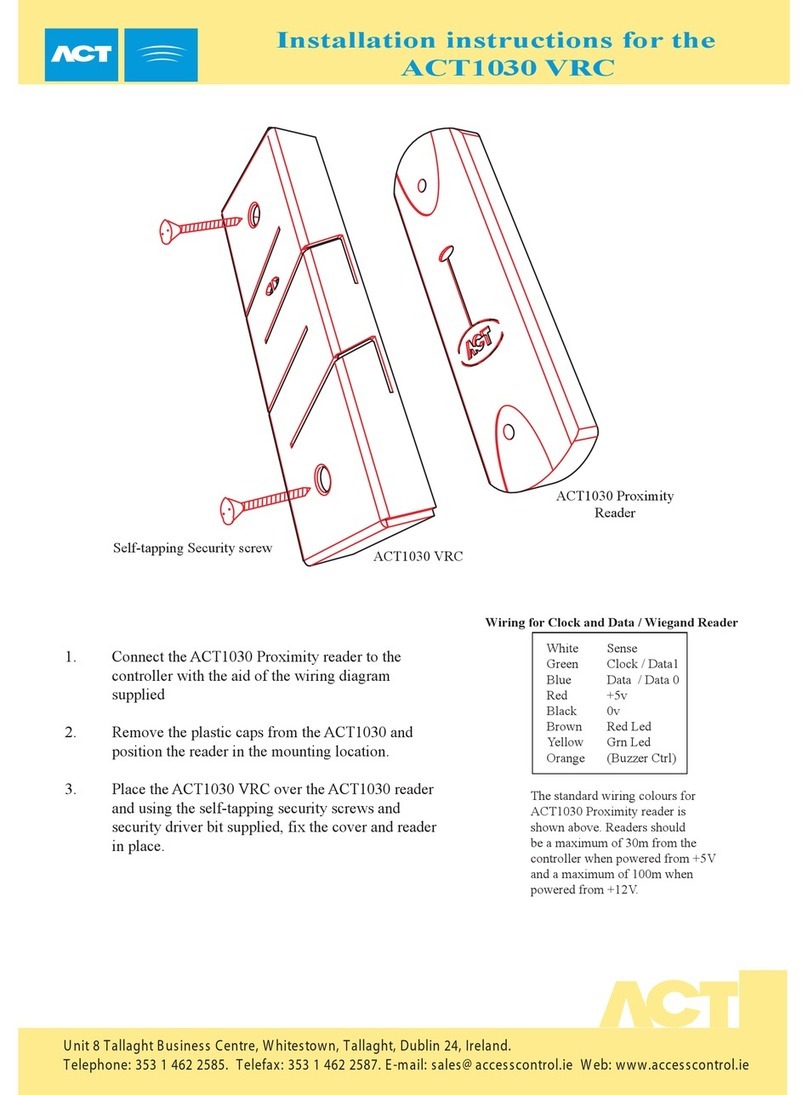

Fig. 2-1: Primary/Master controller mPro400GC-P Fig. 2-2: Primary/Master controller mPro400GCD-P

Feature mPro400GC mPro400GCD-P/-M mPro400GCD-S(H)

TSnet connection No Yes Yes

ArcNet (System Bus) connec-

tion: Connection to

mPro400GC-S, BTS spindles,

System Bus Accessories

(socket trays, stack lights, I/O

boxes)

Yes Yes No

TSnet connection: Connec-

tion to mPro400GCD-S(H) No Yes Yes

Capability for USB Scanner No Yes Yes

Range of input power 115 V or 230 V 100 – 240 VAC 100 – 240 VAC

→ works globally

→ very tolerant to instable main power

supplies

Power supply GFCI, single-phase Switch mode power supply with PFC, single-

phase

UL certified No Yes Yes

mPro400GC replaced by mPro400GCD

6 P2434JH | 2019-08 Apex Tool Group

3

EN 3 mPro400GC replaced by mPro400GCD

If mPro400GC-P/-M is replaced by mPro400GCD-P/-M, certain things need to be considered. Below are

various scenarios and procedures for exchanging controller types.

3.1 Primary/Master controller

Scenario

• mPro400GC-P/-M is replaced by mPro400GCD-P/-M.

• No Secondary controllers connected.

Conditions for new system layout

Procedure

Save parameters from mPro400GC-P/-M:

1. Select Navigator >Administration > Save parameters.

→ The Save parameters dialog opens.

2. Select the storage location and confirm with <OK>. The parameters can be stored on an internal stor-

age device (CF card) or an connected USB drive.

3. Press <All> to save all parameters.

4. Disconnect mPro400GC-P/-M and connect mPro400GCD-P/-M. See documentation P2300HW or

P2309HW.

Set up mPro400GCD-P/-M:

1. Start mPro400GCD-P/-M.

2. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

3. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Load parameters from an internal storage device (CF card) or a connected USB drive to

mPro400GCD-P/-M:

1. If the parameters have been saved on the CF card, insert the old CF card into mPro400GCD-P/-M. If

the parameters have been saved on the USB drive, insert the USB drive into mPro400GCD-P/-M

2. Select Navigator > Administration > Load parameters.

→ The Load parameters dialog opens.

3. Select the previously saved parameters and confirm with <OK>.

4. Press <All> to load all parameters.

Old system layout New system layout

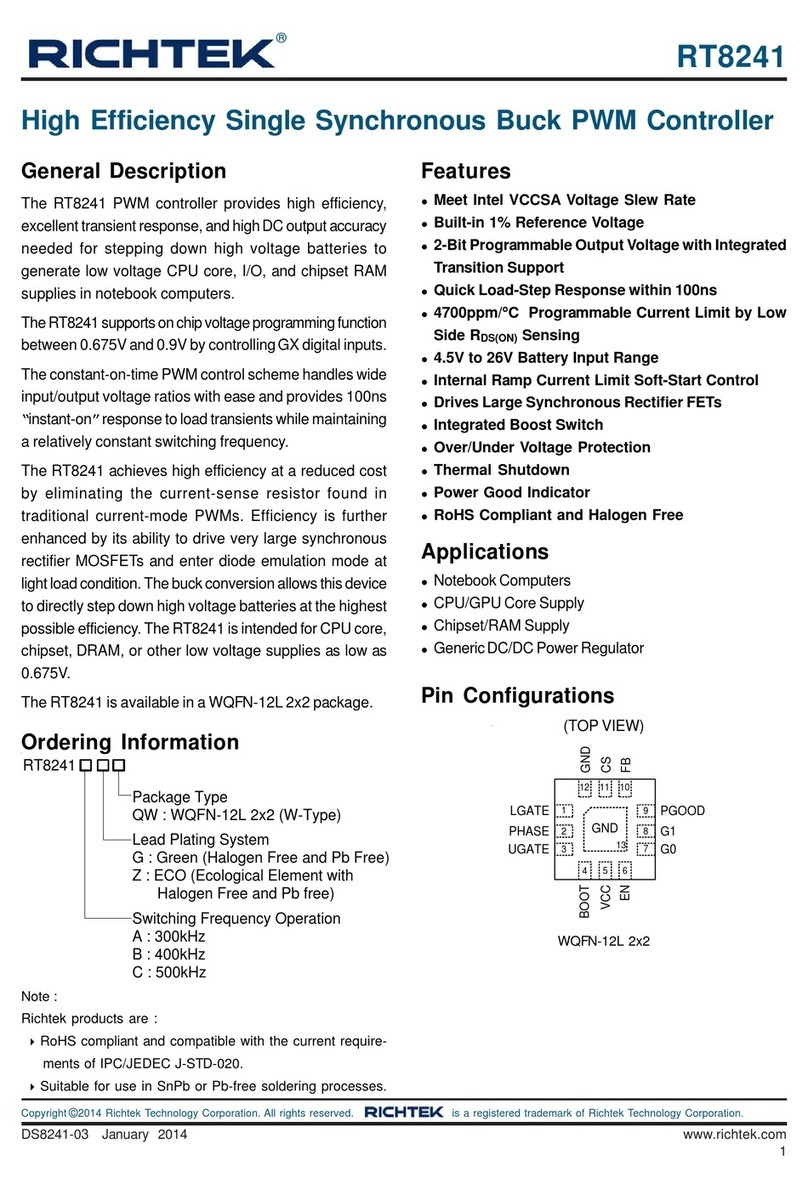

Fig. 3-1: Primary/Master controller mPro400GC Fig. 3-2: Primary/Master controller mPro400GCD

Type Indication

Software version mPro400GCD-P/-M: S168813-1.8.0 or newer.

Operating system 2.7

mPro400GC-P/

mPro400GC-M

mPro400GCD-P/

mPro400GCD-M

Apex Tool Group P2434JH | 2019-08 7

mPro400GC replaced by mPro400GCD

3

EN

Adjust Programmable I/O Mapping:

1. Select Navigator > Tool Setup > I/O.

2. Confirm the messages with <Run it> and <Continue>.

→ The Programmable I/O Mapping dialog opens.

3. Re-parameterize the start switch and the tool light. All signals from PM_DIDO have to be changed to

TM_DIDO.

4. Confirm the change with <OK> and <Accept>.

3.2 Primary/Master controller with existing Secondary controllers

Scenario

• mPro400GC-P/-M is replaced by mPro400GCD-P/-M.

• Existing mPro400GC-S used.

Conditions for new system layout

Signal Input/Output PM_DIDO

Bit

TM_DIDO

Bit

Tool Group Start (SA) Input 0 0

Reverse (TM_LL) Input 1 1

Function button 2 Input - 6

Status (Yellow LED) Output 4 4

Tool OK 1 (Green LED) Output 3 3

Tool NOK 1 (Red LED) Output 2 2

Blue LED Output - 5

Old system layout New system layout

Fig. 3-3: Primary/Master controller mPro400GC

with Secondary controller mPro400GC

Fig. 3-4: Primary/Master controller mPro400GCD

with Secondary controller mPro400GC

Type Indication

Software version mPro400GCD-P/-M: S168813-1.8.0 or newer.

mPro400GC-S: S168025-510

Operating system 2.7

Cables mPro400GCD-P/-M to mPro400GC-S.

System Bus Cable: Part number 544196-XXX

System Bus Terminator Only required for mPro400GC-S: Part number 544197PT

mPro400GC-P/

mPro400GC-M mPro400GC-S mPro400GC-S

544196-XXX

544196-XXX

X21 X31 X32 X31

Arcnet Arcnet

mPro400GCD-P/

mPro400GCD-M mPro400GC-S mPro400GC-S

544196-XXX

544196-XXX544196-XXX

X22 X31 X32 X31

X32

544197PT

Arcnet

mPro400GC replaced by mPro400GCD

8 P2434JH | 2019-08 Apex Tool Group

3

EN Procedure

Save parameters from mPro400GC-P/-M:

1. Select Navigator >Administration > Save parameters.

→ The Save parameters dialog opens.

2. Select the storage location and confirm with <OK>. The parameters can be stored on an internal stor-

age device (CF card) or an connected USB drive.

3. Press <All> to save all parameters.

4. Disconnect mPro400GC-P/-M and connect mPro400GCD-P/-M.

Set up mPro400GCD-P/-M:

1. Use cable 544196-XXX to connect mPro400GCD-P/-M and mPro400GC-S. See documentation

P2300HW or P2309HW.Use following inputs and outputs:

- mPro400GCD-P/-M: output X22

- mPro400GC-S: input X31

1. Use cable 544196-XXX to connect additional mPro400GC-S to the previous mPro400GC-S if neces-

sary. Use following inputs and outputs:

- Previous mPro400GC-S: output X32

- Following mPro400GC-S: input X31

2. Connect the System Bus Terminator 544197PT to X32 at the last mPro400GC-S.

3. Start mPro400GCD-P/-M.

4. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

5. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Load parameters from an internal storage device (CF card) or a connected USB drive to

mPro400GCD-P/-M:

1. If the parameters have been saved on the CF card, insert the old CF card into mPro400GCD-P/-M. If

the parameters have been saved on the USB drive, insert the USB drive into mPro400GCD-P/-M.

2. Select Navigator > Administration > Load parameters.

→ The Load parameters dialog opens.

3. Select the previously saved parameters and confirm with <OK>.

4. Press <All> to load all parameters.

Adjust Programmable I/O Mapping:

1. Select Navigator > Tool Setup > I/O.

2. Confirm the messages with <Run it> and <Continue>.

→ The Programmable I/O Mapping dialog opens.

3. Re-parameterize the start switch and the tool light. All signals from PM_DIDO have to be changed to

TM_DIDO.

4. Confirm the change with <OK> and <Accept>.

Signal Input/Output PM_DIDO

Bit

TM_DIDO

Bit

Tool Group Start (SA) Input 0 0

Reverse (TM_LL) Input 1 1

Function button 2 Input - 6

Status (Yellow LED) Output 4 4

Tool OK 1 (Green LED) Output 3 3

Tool NOK 1 (Red LED) Output 2 2

Blue LED Output - 5

Apex Tool Group P2434JH | 2019-08 9

mPro400GC replaced by mPro400GCD

3

EN

3.3 Primary/Master controller with new Secondary controllers

Scenario

• mPro400GC-P/-M is maintained.

• mPro400GCD-S(H) is added.

Conditions for new system layout

Procedure

Parameterize ethernet interface

1. Select Navigator > Communication > Network settings.

Fig. 3-7: Network settings

2. Enter the ethernet settings in Ethernet Card 2:

Old system layout New system layout

Fig. 3-5: Primary/Master controller mPro400GC Fig. 3-6: Primary/Master controller mPro400GC

with Secondary controller mPro400GCD

Type Indication

Software version mPro400GC-P/-M: S168813-1.8.0 or newer.

mPro400GCD-S(H): S168025-510

Operating system 2.7

Cables mPro400GC-P/-M to mPro400GCD-S(H).

RJ45 to TSnet Cable: Part number S981511(-XX)

mPro400GCD-S(H) to mPro400GCD-S(H).

TSnet Cable: Part number 962037-(XXX)

Parameter Value

IP Address 192 168 245 200

Subnet Mask 255 255 255 0

mPro400GC-P/

mPro400GC-M

mPro400GC-P/

mPro400GC-M mPro400GCD-S(H) mPro400GCD-S(H)

S981511 962037-XXX

X21 X22 X21 X22

TSnet

mPro400GC replaced by mPro400GCD

10 P2434JH | 2019-08 Apex Tool Group

3

EN Set up mPro400GC-P/-M:

1. Use cable S981511 to connect mPro400GC-P/-M and mPro400GCD-S(H). See documentation

P2174HW. Use following inputs and outputs:

- mPro400GC-P/-M: output X21

- mPro400GCD-S(H): input X22 (TSnet in)

2. Use cable 962037-XXX to connect additional mPro400GCD-S(H) to the previous mPro400GCD-S(H) if

necessary. Use following inputs and outputs:

- Previous mPro400GCD-S(H): output X21 (TSnet out)

- Following mPro400GCD-S(H): input X22 (TSnet in)

3. Start mPro400GC-P/-M.

4. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

5. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Install Secondary controllers:

1. Select Navigator > Tool Setup > Install.

→ The Assign Tool dialog opens.

2. The following settings are required:

3. Confirm with <OK>.

The TSnet cable may not be connected to the infrastructure network.

Home network

mPro400GC-P/

mPro400GC-M mPro400GCD-S(H)

Parameter Description

Group Name Select tool group. It is possible to select up to 16 tool groups.

Name Assign a name to the Secondary.

Type Select Secondary.

Apex Tool Group P2434JH | 2019-08 11

mPro400GC replaced by mPro400GCD

3

EN

3.4 Install Primary/Master controller with Secondary controllers mPro400GC

Scenario

• mPro400GCD-P/-M.

• mPro400GC-S is added.

Conditions and Process

See chapter 3.2 Primary/Master controller with existing Secondary controllers, page 7.

3.5 Install Primary/Master controller with Secondary controllers mPro400GCD

Scenario

• mPro400GCD-P/-M.

• mPro400GCD-S(H) is added.

Conditions for new system layout

Old system layout New system layout

Fig. 3-8: Primary/Master controller mPro400GCD with Secondary controller

mPro400GC

mPro400GCD-P/

mPro400GCD-M mPro400GC-S mPro400GC-S

544196-XXX 544196-XXX

X22 X31 X32 X31

X32

544197PT

Arcnet

Old system layout New system layout

Fig. 3-9: Primary/Master controller mPro400GCD with Secondary controller

mPro400GCD

Type Indication

Software version mPro400GCD-P/-M: S168813-1.8.0 or newer.

mPro400GCD-S: S168025-510

Operating system 2.7

Cables mPro400GCD-P/-M to mPro400GCD-S(H).

TSnet Cable: Part number 962037-XXX

mPro400GCD-P/

mPro400GCD-M mPro400GCD-S(H) mPro400GCD-S(H)

962037-XXX

X22

962037-XXX

X21 X21 X22

TSnet TSnet

mPro400GC replaced by mPro400GCD

12 P2434JH | 2019-08 Apex Tool Group

3

EN Procedure

Set up mPro400GCD-P/-M:

1. Use cable 962037-XXX to connect mPro400GCD-P/-M and mPro400GCD-S(H). See documentation

P2300HW or P2309HW.Use following inputs and outputs:

- mPro400GCD-P/-M: output X21

- mPro400GCD-S(H): input X22

2. Use cable 962037-XXX to connect additional mPro400GCD-S(H) to the previous mPro400GCD-S(H) if

necessary. Use following inputs and outputs:

- Previous mPro400GC-S: output X22

- Following mPro400GC-S: input X21

3. Start mPro400GCD-P/-M.

4. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

5. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Install Secondary controllers:

1. Select Navigator > Tool Setup > Install.

→ The Assign Tool dialog opens.

2. The following settings are required:

3. Confirm with <OK>.

The TSnet cable may not be connected to the infrastructure network.

Home network

mPro400GCD-P/

mPro400GCD-M mPro400GCD-S(H)

Parameter Description

Group Name Select tool group. It is possible to select up to 16 tool groups.

Name Assign a name to the Secondary.

Type Select Secondary.

Apex Tool Group P2434JH | 2019-08 13

mPro400GC replaced by mPro400GCD

3

EN

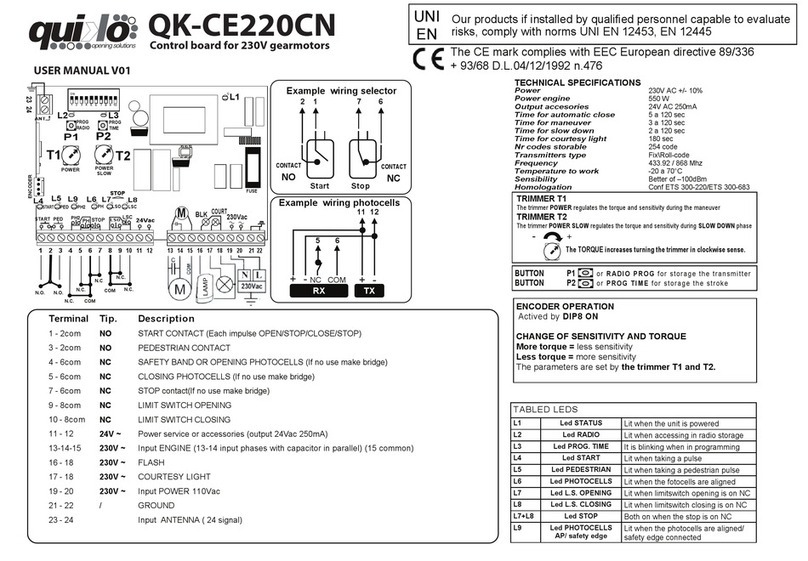

3.6 Primary/Master controller with two types of Secondary controllers

Scenario

• mPro400GCD-P/-M.

• mPro400GC-S and mPro400GCD-S(H) are added.

Conditions for new system layout

Procedure

Set up mPro400GCD-P/-M:

1. Use cable 962037-XXX to connect mPro400GCD-P/-M and mPro400GCD-S(H). See documentation

P2300HW or P2309HW. Use following inputs and outputs:

- mPro400GCD-P/-M: output X21

- mPro400GCD-S(H): input X22

2. Use cable 544196-XXX to connect mPro400GCD-P/-M and mPro400GC-S. Use following inputs and

outputs:

- mPro400GCD-P/-M: output X22

- mPro400GC-S: input X31

Old system layout New system layout

Fig. 3-10: Primary/Master controller mPro400GCD with Secondary controller

mPro400GC and mPro400GCD

Type Indication

Software version mPro400GCD-P/-M: S168813-1.8.0 or newer.

mPro400GCD-S: S168025-510

Operating system 2.7

Cables mPro400GCD-P/-M to mPro400GCD-S(H).

TSnet Cable: Part number 962037-XXX

mPro400GCD-P/-M to mPro400GC-S.

System Bus Cable: Part number 544196-XXX

System Bus Terminator Only required for mPro400GC-S: Part number 544197PT

mPro400GCD-P/

mPro400GCD-M mPro400GCD-S(H) mPro400GC-S

962037-XXX

544196-XXX

mPro400GC-S

544196-XXX

X32

544197PT

X22 X21 X22 X31X31 X32

TSnet

Arcnet Arcnet

mPro400GC replaced by mPro400GCD

14 P2434JH | 2019-08 Apex Tool Group

3

EN

3. Use cable 544196-XXX to connect additional mPro400GC-S to the previous mPro400GC-S if neces-

sary. Use following inputs and outputs:

- Previous mPro400GC-S: output X32

- Following mPro400GC-S: input X31

4. Connect the System Bus Terminator 544197PT to X32 at the last mPro400GC-S.

5. Use cable 962037-XXX to connect additional mPro400GCD-S(H) to the previous mPro400GCD-S(H) if

necessary. Use following inputs and outputs:

- Previous mPro400GCD-S(H): output X21

- Following mPro400GCD-S(H): input X22

6. Start mPro400GCD-P/-M.

7. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

8. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Install Secondary controllers:

1. Select Navigator > Tool Setup > Install.

→ The Assign Tool dialog opens.

2. The following settings are required:

3. Confirm with <OK>.

The TSnet cable may not be connected to the infrastructure network.

Home network

mPro400GCD-P/

mPro400GCD-M mPro400GCD-S(H)

Parameter Description

Group Name Select tool group. It is possible to select up to 16 tool groups.

Name Assign a name to the Secondary.

Type Select Secondary.

Apex Tool Group P2434JH | 2019-08 15

mPro400GC replaced by mPro400GCD

3

EN

3.7 Primary/Master controller with Secondary controllers and Stack Lights

In combination with stack lights, mPro400GC and mPro400GCD controllers cannot be mixed.

3.7.1 mPro400GC

Scenario

• mPro400GC-P/-M and mPro400GC-S are available.

• Stack lights are added.

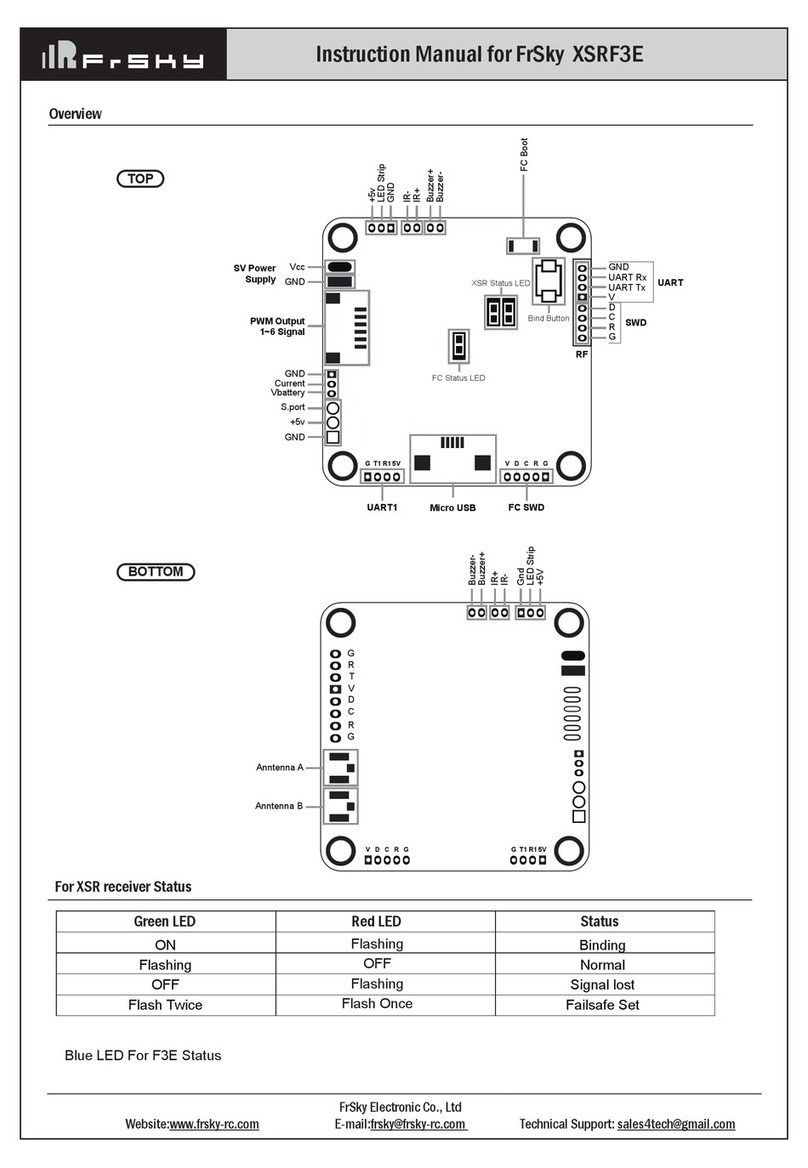

Fig. 3-11: Primary/Master controller mPro400GC with Secondary controller mPro400GC and stack lights

Conditions for new system layout

Procedure

Set up mPro400GCD-P/-M:

1. Use cable 544196-XXX to connect mPro400GC-P/-M and the first stack light. Use following inputs and

outputs:

- mPro400GC-P/-M: output X21

- Stack light: input Arcnet in

2. Use cable 544196-XXX to connect mPro400GC-S to the stack light. Use following inputs and outputs:

- Stack light: output Arcnet out

- mPro400GC-S: input X31

3. Use cable 544196-XXX to connect additional mPro400GC-S or stack lights.

4. Connect the System Bus Terminator 544197PT to the output at the last stack light.

5. Start mPro400GC-P/-M.

6. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

7. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Type Indication

Software version mPro400GC-P/-M: S168813-1.8.0 or newer.

mPro400GC-S:S168025-510

Operating system 2.7

Cables mPro400GCD-P/-M to mPro400GC-S.

System Bus Cable: Part number 544196-XXX

System Bus Terminator Only required for mPro400GC-S or stack lights: Part number 544197PT

mPro400GC-P/

mPro400GC-M mPro400GC-S mPro400GC-S

544196-XXX544196-XXX 544196-XXX

544196-XXX 544196-XXX

X21 X31 X31X32 X32 544197PT

Arcnet Arcnet ArcnetArcnet Arcnet

Arcnet

in

Arcnet

out

Arcnet

in

Arcnet

out

Arcnet

in

Arcnet

out

mPro400GC replaced by mPro400GCD

16 P2434JH | 2019-08 Apex Tool Group

3

EN Parameterize stack lights

1. Assign each stack light its own Arcnet address:

The default Arcnet address is printed on the front of the housing, e.g. 101.

If several stack lights are used, screw on the housing and change the Arcnet address at the rotary con-

trols internally with a screwdriver.

2. Select Navigator > Tool Setup > IO > Run it > Continue on the controller.

→ It opens the Programmable I/O Mapping.

3. Parameterize the inputs and outputs of the stack lights.

Fig. 3-12: Programmable I/O Mapping

The inputs are from bit 0 - 7, the outputs are from bit 8 - 15. For more information see ON / OUTPUTS A-OK

BRIDGE in the supplied BUILDING PLAN of the stack lights.

4. Leave the I/O to save the settings.

The two rotary controls are named LOW and HIGH.

The Arcnet address consists of three digits:

• Digit 1: fixed value „1“

• Digit 2: setting of the rotary control „HIGH“

• Digit 3: setting of the rotary control „LOW“

Example:

Rotary control „HIGH“: 0

Rotary control „LOW“: 3

→ Arcnet address: 103

Item Setting

1Select A-IOS.

2Enter Arcnet address.

3Select the desired signal.

4Enter the bit.

0

2

3

4

5

6 7 8

9

1

32

1 4

Apex Tool Group P2434JH | 2019-08 17

mPro400GC replaced by mPro400GCD

3

EN

3.7.2 mPro400GCD

Scenario

• mPro400GCD-P/-M and mPro400GCD-S(H) are available.

• Stack lights are added.

Fig. 3-13: Primary/Master controller mPro400GCD with Secondary controller mPro400GCD and stack lights

Conditions for new system layout

Procedure

Set up mPro400GCD-P/-M:

1. Use cable 544196-XXX to connect mPro400GCD-P/-M and the first stack light. Use following inputs

and outputs:

- mPro400GC-P/-M: output X22

- Stack lights: input Arcnet in

2. Use cable 544196-XXX to connect additional stack lights.

3. Connect the System Bus Terminator 544197PT to X32 at the last mPro400GC-S.

4. Connect mPro400GCD-P/-M and mPro400GCD-S(H). See chapter 3.5 Install Primary/Master controller

with Secondary controllers mPro400GCD, page 11.

5. Start mPro400GC-P/-M.

6. Ensure that hybrid-capable software is used. The software has to be S168813-1.8.0 or newer.

7. Ensure that the current version of the operating system is used. The operating system has to be 2.7 or

newer.

Type Indication

Software version mPro400GCD-P/-M: S168813-1.8.0 or newer.

mPro400GCD-S: S168025-510

Operating system 2.7

Cables mPro400GCD-P/-M to mPro400GCD-S(H).

TSnet Cable: Part number 962037-XXX

mPro400GCD-P/-M to stack lights.

System Bus Cable: Part number 544196-XXX

System Bus Terminator Only required for stack lights: Part number 544197PT

mPro400GCD-P/

mPro400GCD-M mPro400GCD-S(H) mPro400GCD-S(H)

544196-XXX 544196-XXX 544196-XXX

962037-XXX 962037-XXX

X21 X22 X22X21 544197PT

X22

Arcnet Arcnet Arcnet

TSnet TSnet

Arcnet

in

Arcnet

out

Arcnet

in

Arcnet

out

Arcnet

in

Arcnet

out

mPro400GC replaced by mPro400GCD

18 P2434JH | 2019-08 Apex Tool Group

3

EN Parameterize stack lights

1. Assign each stack light its own Arcnet address:

The default Arcnet address is printed on the front of the housing, e.g. 101.

If several stack lights are used, screw on the housing and change the Arcnet address at the rotary con-

trols internally with a screwdriver.

2. Select Navigator > Tool Setup > IO > Run it > Continue on the controller.

→ It opens the Programmable I/O Mapping.

3. Parameterize the inputs and outputs of the stack lights.

Fig. 3-14: Programmable I/O Mapping

The inputs are from bit 0 - 7, the outputs are from bit 8 - 15. For more information see ON / OUTPUTS A-OK

BRIDGE in the supplied BUILDING PLAN of the stack lights.

4. Leave the I/O to save the settings.

The two rotary controls are named LOW and HIGH.

The Arcnet address consists of three digits:

• Digit 1: fixed value „1“

• Digit 2: setting of the rotary control „HIGH“

• Digit 3: setting of the rotary control „LOW“

Example:

Rotary control „HIGH“: 0

Rotary control „LOW“: 3

→ Arcnet address: 103

Item Setting

1Select A-IOS.

2Enter Arcnet address.

3Select the desired signal.

4Enter the bit.

0

2

3

4

5

6 7 8

9

1

32

1 4

0819 | Cleco® is a registered trademark of Apex Brands, Inc. | © 2019

Apex Tool Group, LLC

Phone: +1 (800) 845-5629

Phone: +1 (919) 387-0099

Fax: +1 (803) 358-7681

www.ClecoTools.com

www.ClecoTools.de

POWER TOOLS SALES & SERVICE CENTERS

Please note that all locations may not service all products.

Contact the nearest Cleco® Sales & Service Center for the appropriate facility to handle your service

requirements.

Sales Center

Service Center

NORTH AMERICA | SOUTH AMERICA

DETROIT, MICHIGAN

Apex Tool Group

2630 Superior Court

Auburn Hills, MI 48236

Phone: +1 (248) 393-5644

Fax: +1 (248) 391-6295

LEXINGTON,

SOUTH CAROLINA

Apex Tool Group

670 Industrial Drive

Lexington, SC 29072

Phone: +1 (800) 845-5629

Phone: +1 (919) 387-0099

Fax: +1 (803) 358-7681

MEXICO

Apex Tool Group

Vialidad El Pueblito #103

Parque Industrial Querétaro

Querétaro, QRO 76220

Mexico

Phone: +52 (442) 211 3800

Fax: +52 (800) 685 5560

BRAZIL

Apex Tool Group

Av. Liberdade, 4055

Zona Industrial Iporanga

Sorocaba, São Paulo

CEP# 18087-170

Brazil

Phone: +55 15 3238 3870

Fax: +55 15 3238 3938

EUROPE | MIDDLE EAST | AFRICA

ENGLAND

Apex Tool Group GmbH

C/O Spline Gauges

Piccadilly, Tamworth

Staffordshire B78 2ER

United Kingdom

Phone: +44 1827 8727 71

Fax: +44 1827 8741 28

FRANCE

Apex Tool Group SAS

25 Avenue Maurice Chevalier -

ZI

77330 Ozoir-La-Ferrière

France

Phone: +33 1 64 43 22 00

Fax: +33 1 64 43 17 17

GERMANY

Apex Tool Group GmbH

Industriestraße 1

73463 Westhausen

Germany

Phone: +49 (0) 73 63 81 0

Fax: +49 (0) 73 63 81 222

HUNGARY

Apex Tool Group

Hungária Kft.

Platánfa u. 2

9027 Györ

Hungary

Phone: +36 96 66 1383

FAX: +36 96 66 1135

ASIA PACIFIC

AUSTRALIA

Apex Tool Group

519 Nurigong Street, Albury

NSW 2640

Australia

Phone: +61 2 6058 0300

CHINA

Apex Power Tool Trading

(Shanghai) Co., Ltd.

2nd Floor, Area C

177 Bi Bo Road

Pu Dong New Area, Shanghai

China 201203 P.R.C.

Phone: +86 21 60880320

Fax: +86 21 60880298

INDIA

Apex Power Tool India

Private Limited

Gala No. 1, Plot No. 5

S. No. 234, 235 & 245

Indialand Global

Industrial Park

Taluka-Mulsi, Phase I

Hinjawadi, Pune 411057

Maharashtra, India

Phone: +91 020 66761111

JAPAN

Apex Tool Group Japan

Korin-Kaikan 5F,

3-6-23 Shibakoen, Minato-

Ku,

Tokyo 105-0011, JAPAN

Phone: +81-3-6450-1840

Fax: +81-3-6450-1841

KOREA

Apex Tool Group Korea

#1503, Hibrand Living Bldg.,

215 Yangjae-dong,

Seocho-gu, Seoul 137-924,

Korea

Phone: +82-2-2155-0250

Fax: +82-2-2155-0252

This manual suits for next models

1

Table of contents

Other Apex Digital Controllers manuals