Rhein-Nadel Automation GmbH 2

VT-BA-ESR2500-2800_EN-2020 / 09.04.2019 SJ

Table of Contents

1. About this document............................................................................................................4

2. Safety directives..................................................................................................................4

2.1. Design of safety directives ..................................................................................................4

2.2. Fundamental safety directives.............................................................................................4

2.3. Personnel............................................................................................................................4

2.4. Intended use........................................................................................................................5

2.5. Residual hazards.................................................................................................................5

2.5.1. Device.................................................................................................................................5

2.5.2. Motor protection ..................................................................................................................5

2.5.3. Degree of protection - Protection of persons and equipment ..............................................6

3. Product information.............................................................................................................6

3.1. Functional description .........................................................................................................6

3.2. Standard features................................................................................................................6

3.3. Applied standards................................................................................................................7

4. Installation and commissioning............................................................................................7

4.1. Sequence of operations for installation and commissioning................................................7

4.2. Mechanical installation........................................................................................................8

4.3. Electrical installation............................................................................................................8

4.4. Commissioning....................................................................................................................9

4.5. Choice of the right current range.........................................................................................9

4.6. Sensor connection.............................................................................................................12

4.7. Connection diagram..........................................................................................................13

4.8. Voltage change .................................................................................................................14

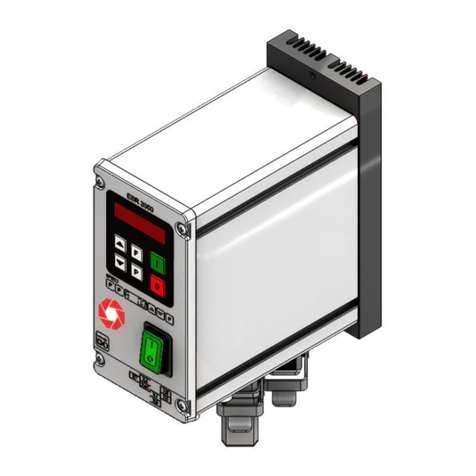

5. Operator panel and display of the controller......................................................................15

5.1. Operator panel - Display ...................................................................................................15

5.2. Navigating through the menus...........................................................................................16

5.3. Main menu ........................................................................................................................16

5.3.1. The "Status" screen:..........................................................................................................16

5.3.2. The "Info" screen:..............................................................................................................17

5.3.3. The "Extended" screen:.....................................................................................................17

5.3.4. Summary of ESR 2500, ESR2800 main menu..................................................................18

6. The set-up menu...............................................................................................................18

6.1. List of set-up menu items ..................................................................................................18

6.1.1. Accumulation checker (sensor inputs)...............................................................................19

6.1.2. Ramps...............................................................................................................................19

6.1.3. Display calibration.............................................................................................................20

6.1.4. Communication / connector XS3.......................................................................................20

6.1.5. Analogue speed input........................................................................................................21

6.1.6. High / Low speed...............................................................................................................21

6.1.7. Multiple settings.................................................................................................................21

6.1.8. Active braking....................................................................................................................22

6.1.9. Changing the password.....................................................................................................22

6.1.10. Activation code..................................................................................................................22

7. Calibration menu...............................................................................................................22

7.1. List of calibration menu items............................................................................................22

7.1.1. Start calibration .................................................................................................................22

7.1.2. Fine tuning ........................................................................................................................23

7.1.3. Current sensor configuration.............................................................................................23

7.1.4. Set max. current................................................................................................................23

7.1.5. Mode.................................................................................................................................23

7.1.6. Changing the password.....................................................................................................23

7.2. Calibration process............................................................................................................24

8. Memory Reset...................................................................................................................28