19Revision 5, status03.2016

English.

1. Safety regulations/

installation notes

• When working on the device, observe the national

safety rulesandregulationsfor the prevention of

accidents.

• Disregarding these safety regulationsmay result in

death, seriouspersonal injury or damage to equip-

ment.

• The device may only be startedup, assembled,

modifiedor retrofittedby an authorizedelectrician.

• Before working on the device, disconnect the power.

• For emergency stop applications, amachine must

be preventedfromrestarting automatically by a

higher-level control system!

• During operation, partsof electrical switching

devicescarry hazardousvoltages.

• During operation, the protective coversmust not be

removedfromthe electric switchgear!

• Keep the instruction sheet in asafe place.

• The device isan associateditemof equipment and

must not be installedin potentially explosive areas.

Adhere to the relevant safety regulationswhen set-

ting up andoperating the relevant equipment.

• The safety regulationsapplicable when motorsare

usedin the Ex areamust be compliedwith (ATEX

directive 2014/34/EU).

• If the „Automatic RESET“ mode isused, the drive

isswitchedon again after the cooling time has

expired- if acontrol signal isstill present. The cool-

ing time is20 minutes. For applicationsin the Ex-

protection area, automatic restart isnot permitted.

• The device may not be subjectedto mechanical

andthermal loads that exceedthe thresholds

specifiedin the operating manual. If required, the

device shouldbe installedin an appropriate housing

with suitable protection (e.g. IP54) according to

IEC 60529/EN 60529 to provide protection against

mechanical andelectrical damage. Where dustsare

present, the device must be installedin asuitable

housing (at least IP64) according to EN 61241.

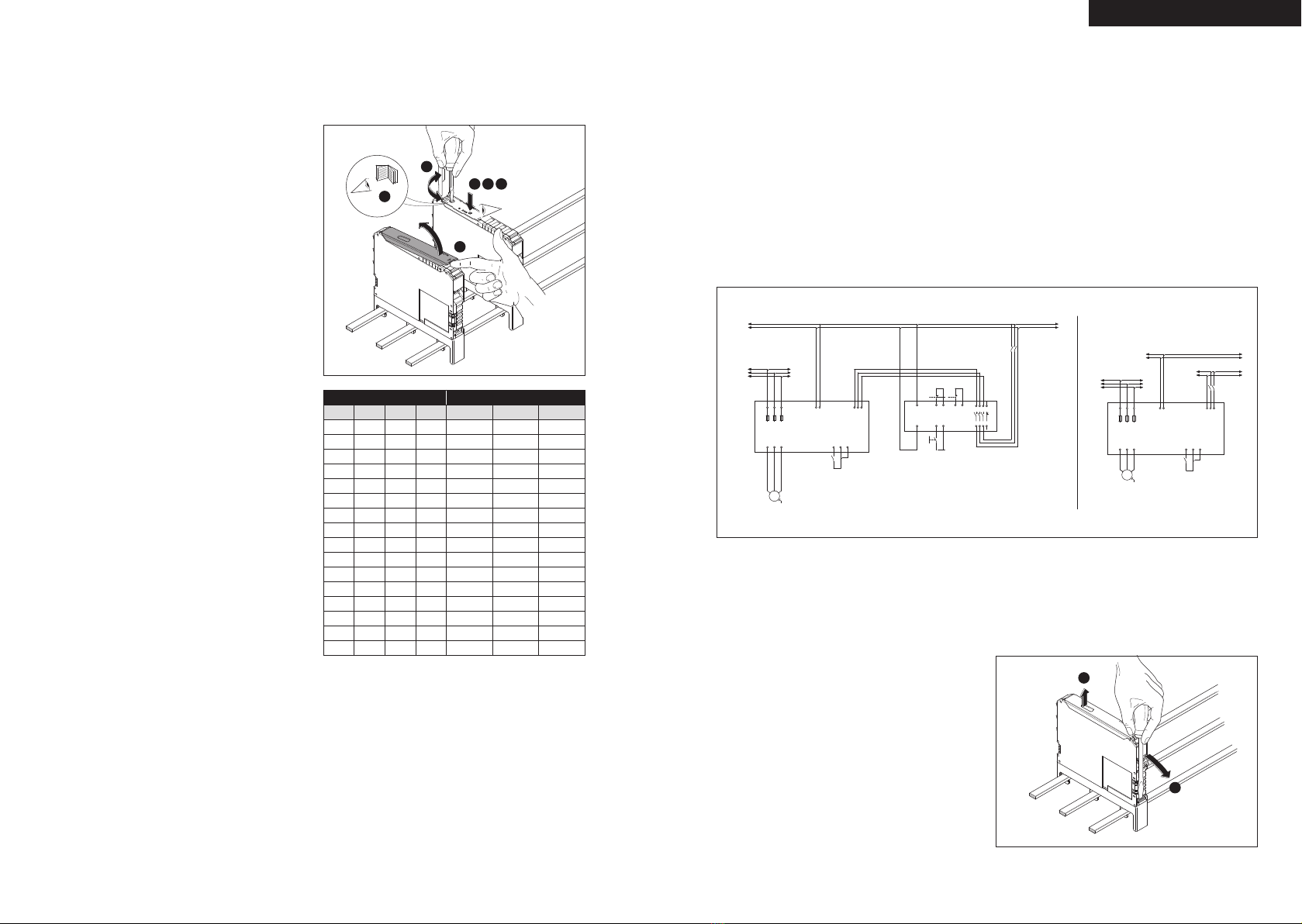

• Installation shouldbe carriedout following the

instructionsprovidedin the operating instructions.

The circuitsinside the device must not be accessed

during operation.

• The itemcannot be repairedby the user andhas to

be replacedby an equivalent device. Repairsmay

only be carriedout by the manufacturer.

• The safety dataandfeaturesaccording to the EC-

type examination certificate must be observed.

• The device carriesout diagnosticson the functions

when the drive isswitchedon or when it isswitched

off. In addition, an authorizedelectrician or askilled

worker who iswell acquaintedwith the relevant

standards can conduct the „Motor overload

protection“ safety function test. For thistest, the

drive must be operatedwith right or left rotation

(forwardor reverse running), andthe current flow in

aconductor interrupted(e.g. by removing the fuse

in the L1 or L3 phase). The hybridmotor starter then

switchesoff the drive within 1.5 to 2s. The LEDsfor

right or left rotation (forwardor reverse running) go

out andthe ERR-LED andthe reply output are set.

• The device must be securedwith the help of an ac-

cess protection during safety-relatedapplications.

• Only use power supply unitswith safe isolation and

PELV in accordance with EN 50178/VDE 0160 (PELV).

Thispreventsshort circuitsbetween primary and

secondary sides.

Scope of use

• In circuitsin potentially dust-explosive areas of

zones21 and22, it must be guaranteedthat the

equipment connectedto thiscircuit complieswith

category 2D or 3D or iscertifiedas such.

• Thisisaproduct for environment A (industry). In

environment B (household), thisdevice can cause

undesiredradio interference; in such acase, the

user may be under obligation to implement appropri-

ate measures.

• MOTUS® has been developedfor the operation of

AC motorswith sinusoidal, symmetrical load andfor

evenly distributed3-phase ohmic loads. The hybrid

motor starter has areversing function, current

monitoring andsafety function. The internal locking

circuit andload wiring reduce the amount of cable

required.