2

PROFESSIONAL INNOVATIVE BRANDING SERVICE

3

Contents Contents

5 Menu Operation ....................................................................................................................... 18

5.1 Menu Introduction ............................................................................................................ 18

5.1.1 Menu Structure ............................................................................................................ 18

5.1.2 Introduction to Front Panel Operations .................................................................... 20

5.1.3 Key Operations and Touch Screen Operation ........................................................... 20

5.2 Menu Operation ................................................................................................................ 23

5.2.1 Setting Item ................................................................................................................ 23

5.2.1.1 Output & More Setting ........................................................................................ 23

5.2.1.2 Measurement Setting ......................................................................................... 28

5.2.1.3 Waveform Viewer Setting .................................................................................. 32

5.2.1.4 Limitation Setting ............................................................................................... 32

5.2.2 Menu Setting ............................................................................................................... 33

5.2.2.1 Config Setting ..................................................................................................... 33

5.2.2.2 LCD Setting ......................................................................................................... 41

5.2.2.3 Calibration ........................................................................................................... 43

5.2.2.4 Other Setting ....................................................................................................... 43

5.2.3 Output Mode .............................................................................................................. 44

5.2.3.1 PLD Testing ......................................................................................................... 44

5.2.3.2 Harmonics .......................................................................................................... 49

5.2.3.3 IEC Standard ........................................................................................................ 56

5.2.3.4 Special Func ........................................................................................................ 74

5.2.4 Parallel/Series/3-Phase ............................................................................................. 79

5.2.5 Store/Recall ................................................................................................................ 79

5.2.6 Lock ............................................................................................................................. 81

6 Master-slave Mode Operation ................................................................................................ 82

6.1 Setting the Units as Slave ................................................................................................. 82

6.2 Setting the Unit as Master ................................................................................................ 83

6.2.1 Parallel System ........................................................................................................... 82

6.2.2 Series System ............................................................................................................. 86

6.2.3 3-Phase System .......................................................................................................... 87

6.2.4 Error List of Master-slave Mode ................................................................................ 91

6.2.5 Function Instruction ................................................................................................... 91

7 Calibration ............................................................................................................................... 93

7.1 Calibration Equipment Required ...................................................................................... 93

7.2 Calibration Procedure ....................................................................................................... 93

7.2.1 Volt Setting & Measurement Calibration .................................................................. 94

7.2.2 Current Measurement Calibration ............................................................................. 95

7.2.2.1 I Range High, AC Low Current Coefficient ......................................................... 96

7.2.2.2 I Range High, AC High Current Coefficient ........................................................ 96

7.2.2.3 I Range High, DC Low Current Coefficient ......................................................... 97

7.2.2.4 I Range High, DC High Current Coefficient ....................................................... 97

7.2.3 Saving Calibration Coefficient ................................................................................... 98

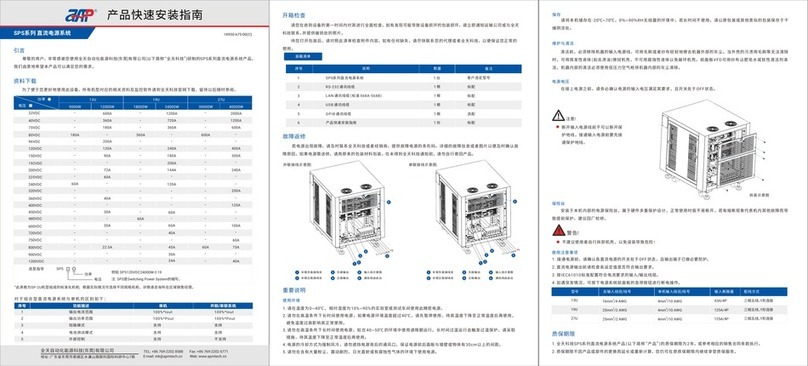

8 Installation ................................................................................................................................ 99

8.1 Product Dimensions .......................................................................................................... 99

8.2 Installing Rack Mount Handles ...................................................................................... 100

8.3 Installing the Optional Interface Cards .......................................................................... 100

8.4 Shelf Mounting Diagram of AC Source ......................................................................... 102

8.5 Input Connection ............................................................................................................. 102

8.6 Output Connection .......................................................................................................... 104

8.7 Remote Compensation .................................................................................................. 105

9 Troubleshooting .................................................................................................................... 106

10 Recycling and Disposal ....................................................................................................... 108

11 Contact Us ........................................................................................................................... 108

Appendix A Specifications ....................................................................................................... 109

Appendix B Fixed Waveforms .................................................................................................. 113

Appendix C Warranty ................................................................................................................ 123

PROFESSIONAL INNOVATIVE BRANDING SERVICE