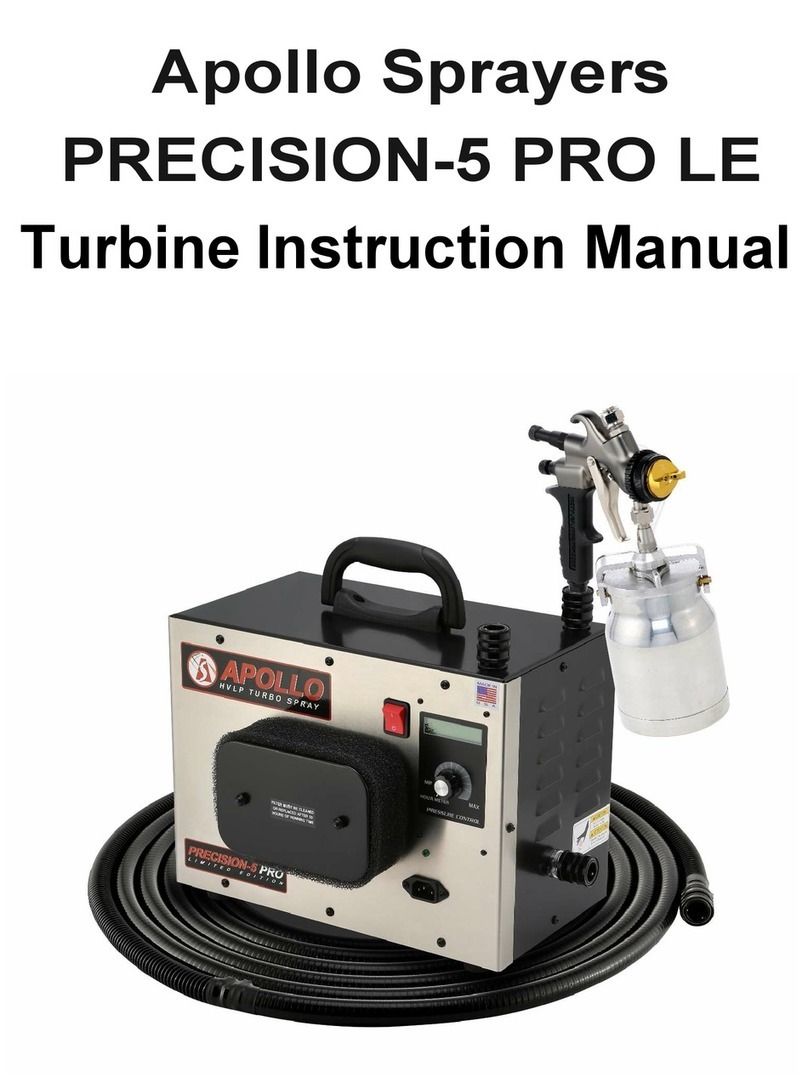

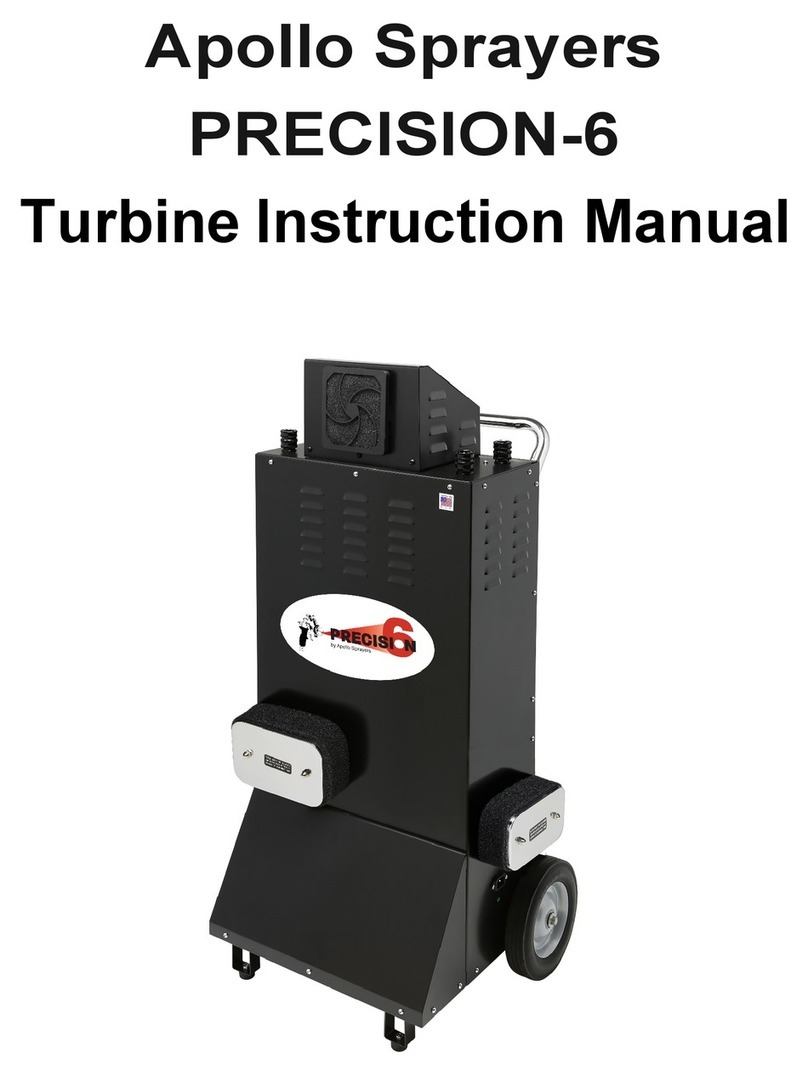

3 Apollo Turbine Model Precision-6 PRO

The model Precision-6 PRO is the newest Precision Series turbine system by Apollo

Sprayers International, Inc. Apollo’s Precision Air Control Technology (PACT) allows you

to control the air pressure from the turbine to within 1/10th of a PSI. Besides the ability to

control your air supply the P6 model also has built in filter warning, overheat

control and a digital hour meter.

The Precision-6 PRO comes supplied with one spray gun

and a 32’ air hose.

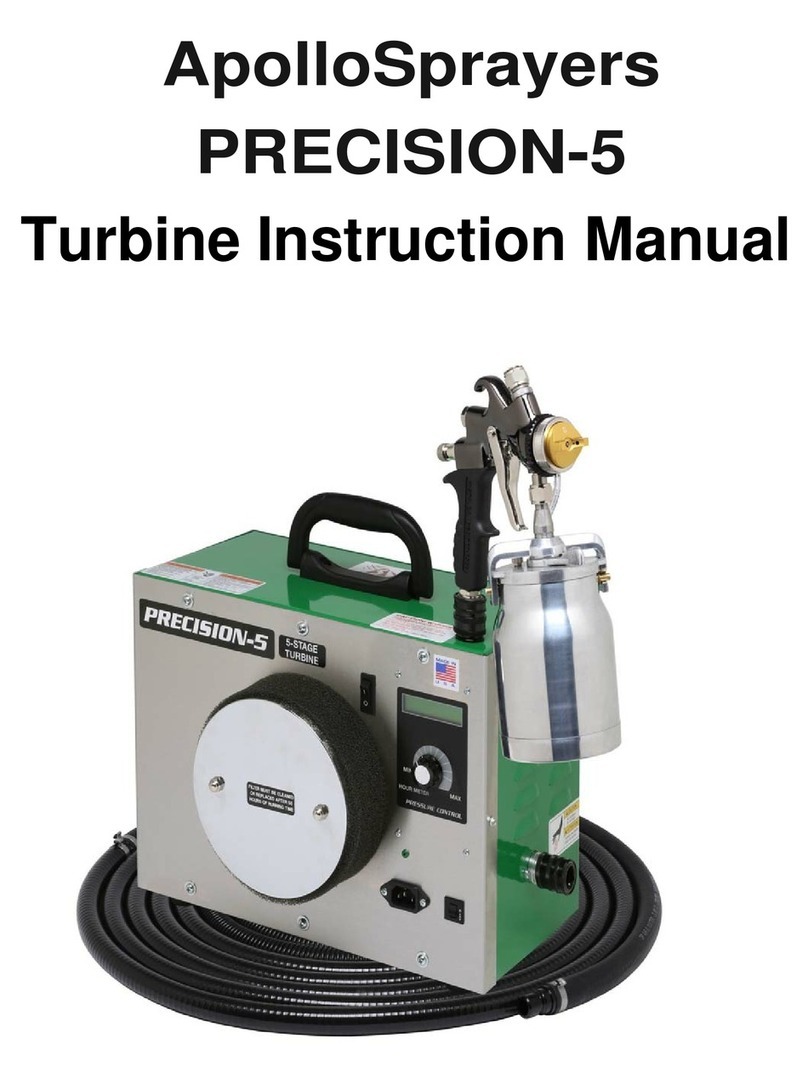

In order to operate the Precision-6 PRO you have to connect the air hose and spray

gun. The turbine will not operate correctly without back pressure to the motor, which

means the spray gun and air hose need to be connected. The Precision-6 PRO is NOT

compatible with “Bleeder” style spray guns. Pull back the ring on the female quick

connect located on the turbine and push the male end of the air hose into it, then

release the ring. Pull back the ring on the female quick connect on the hose and push

it onto the male connector at the bottom of the spray gun handle. Your system is now

connected. Put some paint in the cup and you’re ready to spray.

To control the air pressure on the Precision-6 PRO turbine, connect the spray gun

and air hose with the turbine. Plug the turbine into the appropriate voltage for your

model. It is a good idea to turn the pressure to the “Hour Meter” position to start.

Once you have rotated the dial to the “Hour Meter”, push the ON/OFF switch to

the ON position. The factory has calibrated your turbine motor for the maximum

spraying output pressure possible with the high power 6-stage motor. To get an

accurate stable spraying pressure it is advised that you let the turbine warm up for

about 5-10 minutes before spraying. Once the turbine motor is warm the LCD will

give you an accurate pressure reading to 1/10th PSI and hold it there until you turn

it off.

In order to get the most motor longevity out of your motor it is important to

understand the difference between static or sealed pressure vs. flow pressure.

When setting the turbine pressure for spraying you should always set the “flow”

pressure, this is the pressure when you are pulling the trigger on the spray gun.

You can set the flow pressure by connecting the spray gun and turning the system

on. Turn the material flow screw on the spray gun clockwise until it stops. This

will prevent you from accidentally releasing any material in the cup. You

only

need

to release the air pressure from the spray gun, not the material in order to set the flow pressure. This is why it

is preferable to set the pressure without any material in the cup. Pull the trigger and release the air from the spray

gun. While continuing to pull the trigger, adjust the pressure on the turbine to the spraying pressure of your choice.

NEVER just turn the pressure all the way to Max. This will make the motor try to give you maximum sealed

pressure, which will only create more heat and reduce the life of your motor. The MAX spraying pressure with the

PRECISION-5 is approximately 8.2 PSI depending on the motor, some are a little less. Therefore, when setting the

MAX pressure rotate the pressure control until the pressure does not increase any more with the trigger pulled, this

is usually about 2-3 o’clock on the dial. Once you have set the pressure, release the trigger. The pressure will stay

where you set

it. Pull

the trigger again and watch the LCD screen. You will notice the air pressure drop and then go

back to where you set the pressure. This will work for any pressure setting. NEVER set the turbine at full power with

the trigger not pulled. This will not give you any additional spraying pressure and will only overwork and possibly

overheat your turbine motor when not being used.

The control board will automatically adjust the motor speed to compensate for barometric pressure and elevation. The pressure

reading will always be extremely accurate. To decrease the pressure from the maximum setting simply turn the knob

underneath the LCD pressure display counter-clockwise, toward “MIN”. To increase the pressure once reduced, turn the

knob clockwise, toward “MAX”. As you turn the knob, the pressure will increase or decrease accordingly. The scale behind

the knob is there only to indicate the direction to increase and decrease the pressure. The scale does not represent any

settings for the air pressure.

The viscosity of the coating you want to spray will determine the amount of pressure needed. The thicker your viscosity,

the more pressure you will need to atomize your coating. For highest efficiency, use the lowest pressure that produces

the best atomization and finish results. If you experience “Orange Peel”, increase the pressure. If you have too much

Precision 6 PRO with

7600 Spray Gun

High Power 6-Stage Turbine

110 - 120 volts, 60Hz

15 amps, 1.85 H.P

220 - 240 volts, 50Hz,

8 amps 1.75H.

Dual air filtration

Single spray gun

Weight: 31lbs (14.1kg)

Height: 12” (30.48cm)

Width: 8.5” (21.6cm)

Length: 15” (38.1cm)

All

EU

units

shipped

All 120 volt units are tested and certified