~2~

TableofContents

1Safety.............................................................................................................................................3

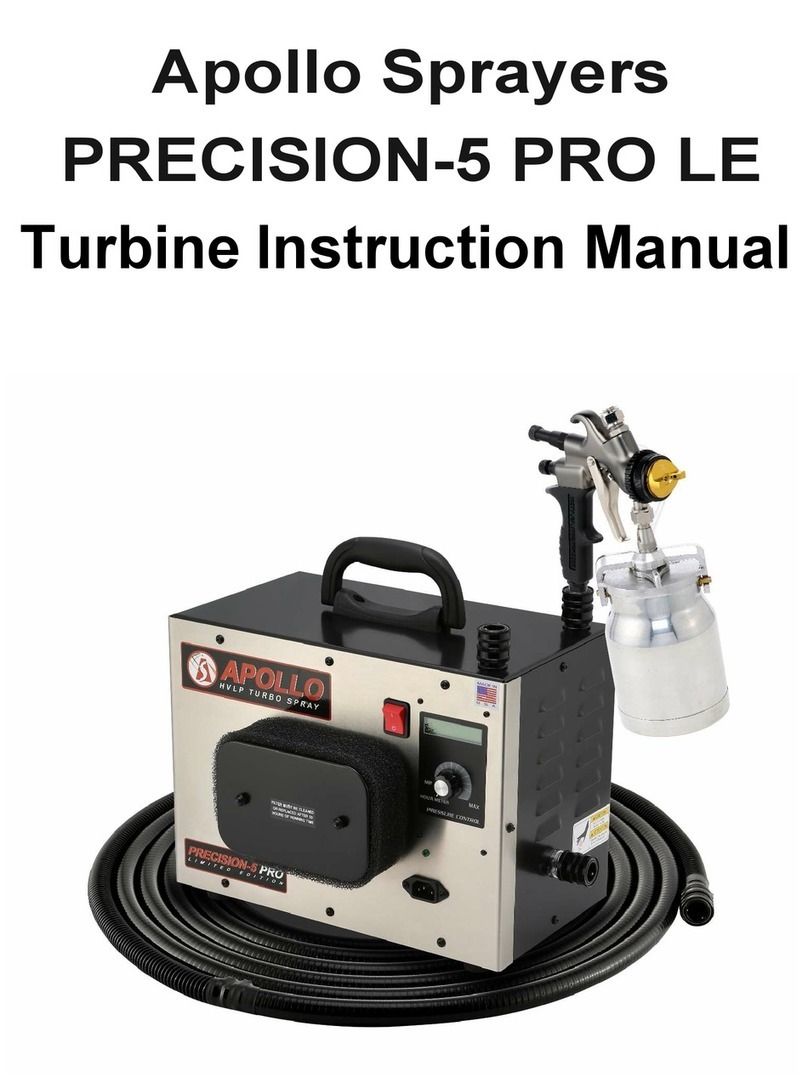

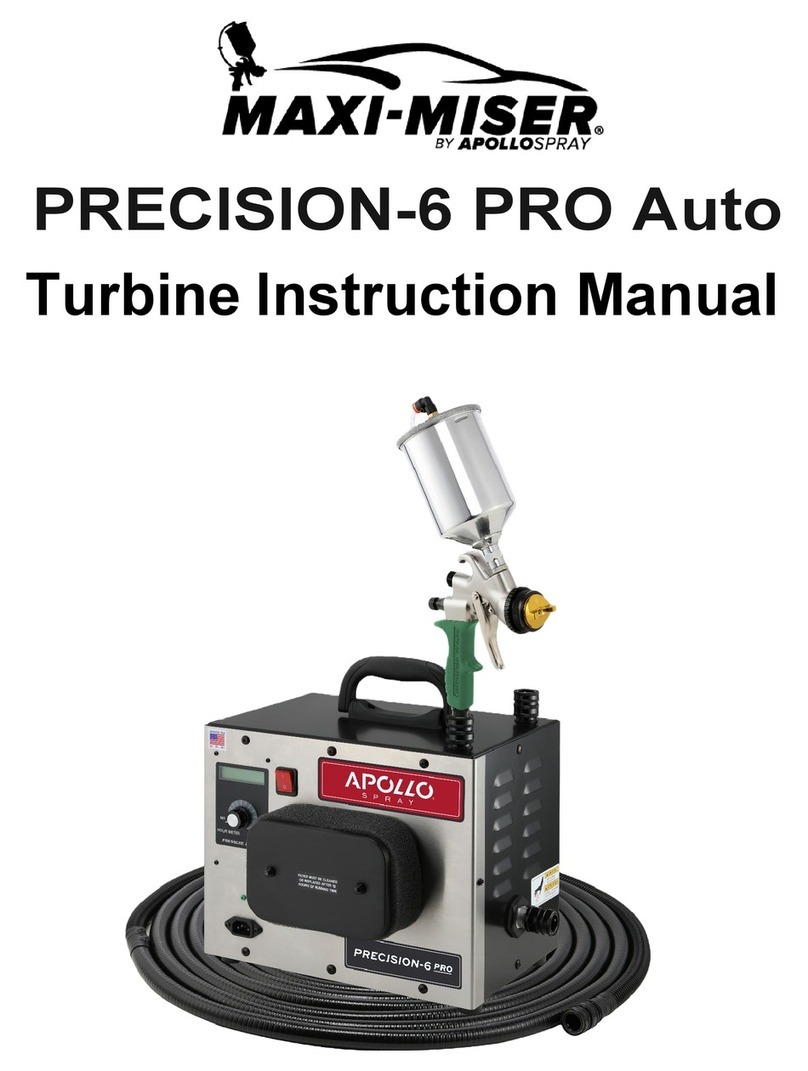

2Maxi-Miser™ Spray Finishing Systems..........................................................................................5

3 How Your Maxi-Miser™ Turbo System Works................................................................................5

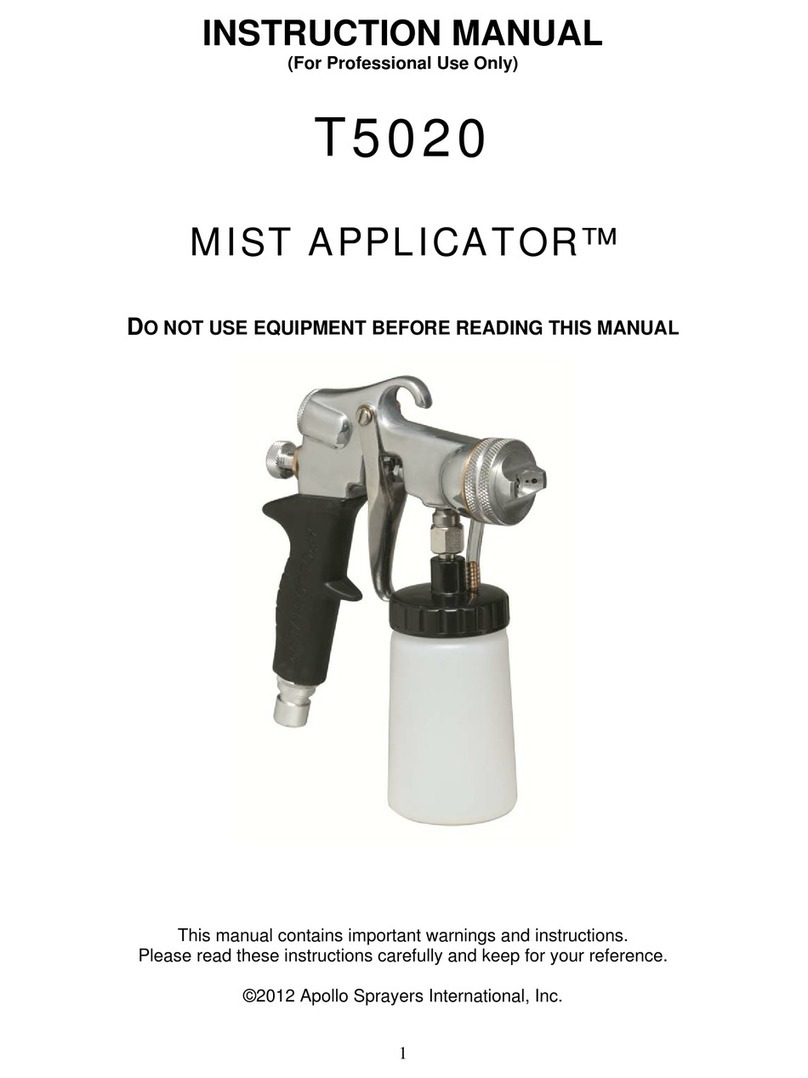

4How Your PBC-GTO™ Spray Gun Works......................................................................................6

5Preparing To Use Your Maxi-Miser™ Turbo System......................................................................6

6Setting up Your PBC-GTO™ Spray Gun.........................................................................................7

6.1Operating your PBC-GTO Spray Gun......................................................................................8

6.2 Spray Gun Technique............................................................................................................10

6.3 Cleaning Your PBC-GTO Spray Gun ....................................................................................11

6.3.1 Partial Cleaning................................................................................................................11

6.3.2 Thorough Cleaning ..........................................................................................................12

6.3.3 Re-Assemble The Spray Gun..........................................................................................13

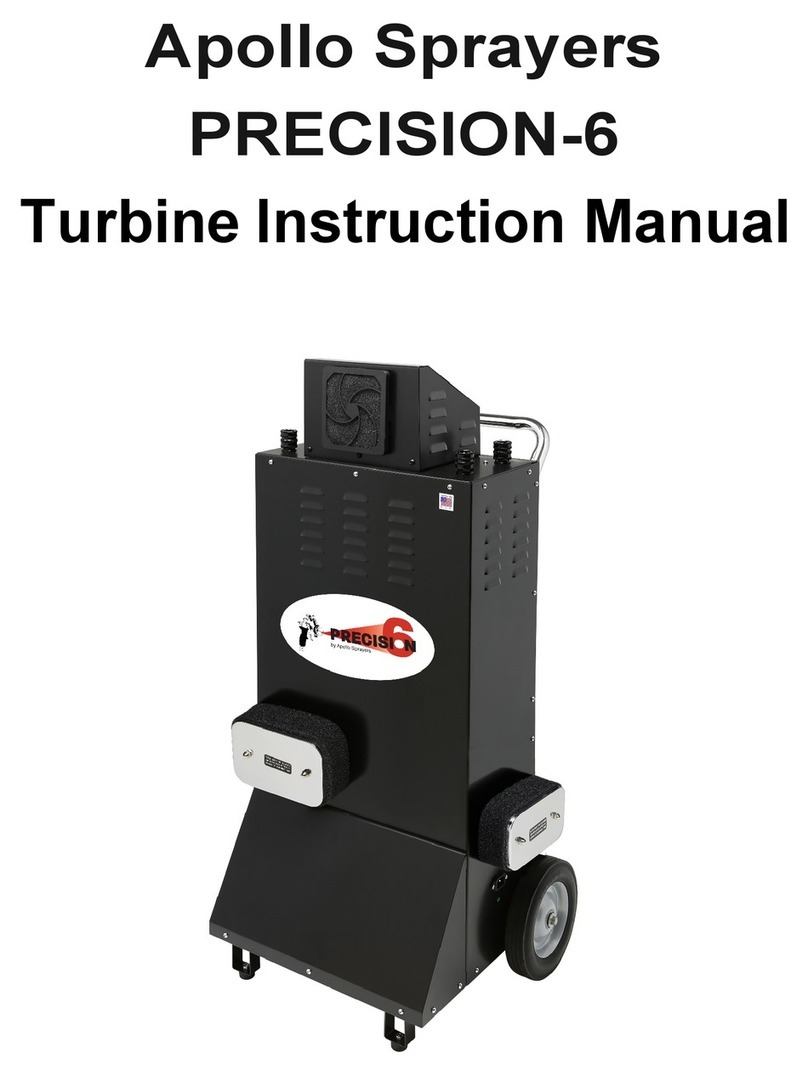

7Get To Know Your Maxi-Miser™ Turbo System...........................................................................18

8 Maxi-Miser™ 2000 Operation......................................................................................................18

9 Turbo Air Pressure and Viscosity ................................................................................................19

10 Using Pressure Pots with Turbo Systems....................................................................................20

10.1 Testing Air Pressure in a Pressure Pot...................................................................................21

10.1.1 Cleaning Your Pressure Pot ...........................................................................................21

11 Record of Turbo Use....................................................................................................................22

12Record of Turbo Maintenance......................................................................................................22

13 Turbo Maintenance and Cleaning................................................................................................23

13.1 Pre-Filter Maintenance ..........................................................................................................27

13.2 Filter Maintenance.................................................................................................................24

14 Model 4500 Diagram ...................................................................................................................25

15 Model 4500 Parts List..................................................................................................................26

16 Model 4550 Diagram ...................................................................................................................27

17 Model 4550 Parts List..................................................................................................................28

18 Geniune Apollo Accessories........................................................................................................29

19 Warranty......................................................................................................................................31