4802961 Rev. 00

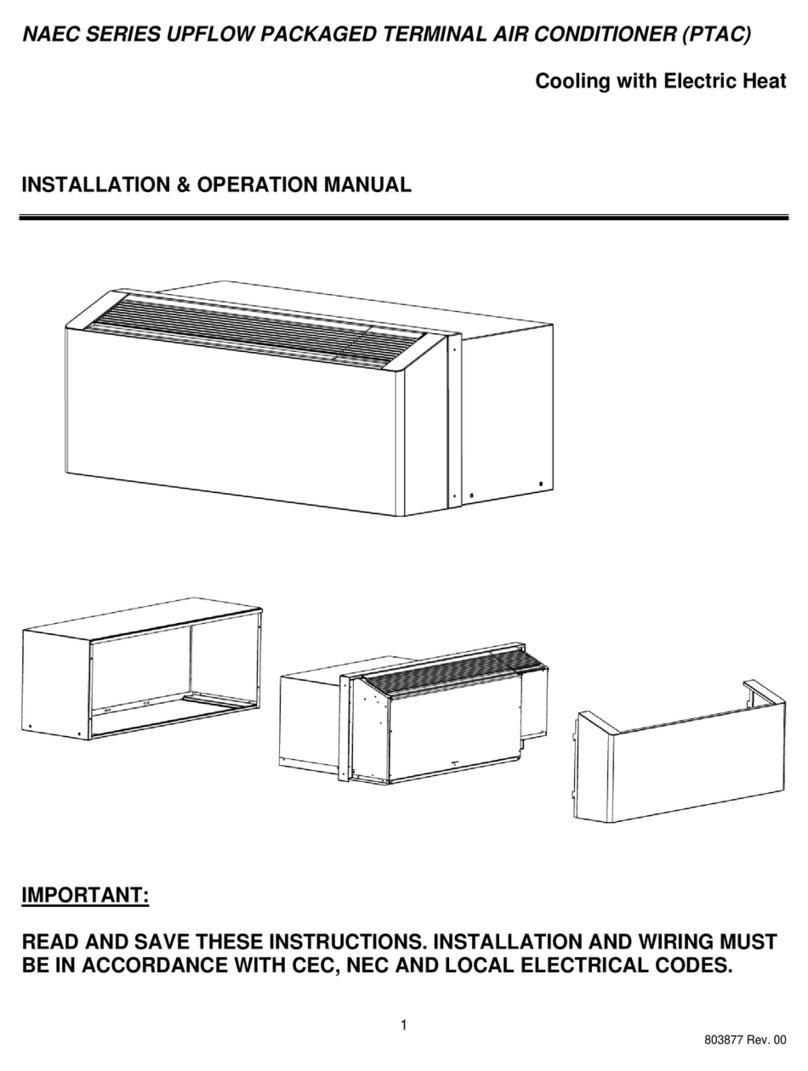

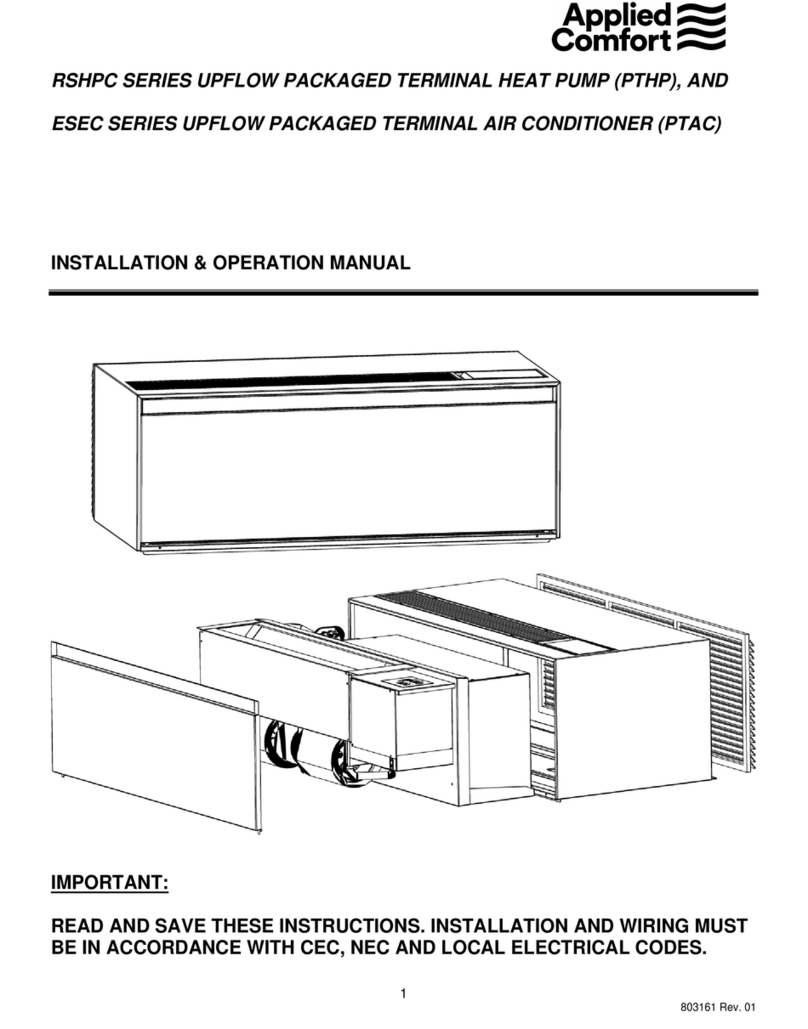

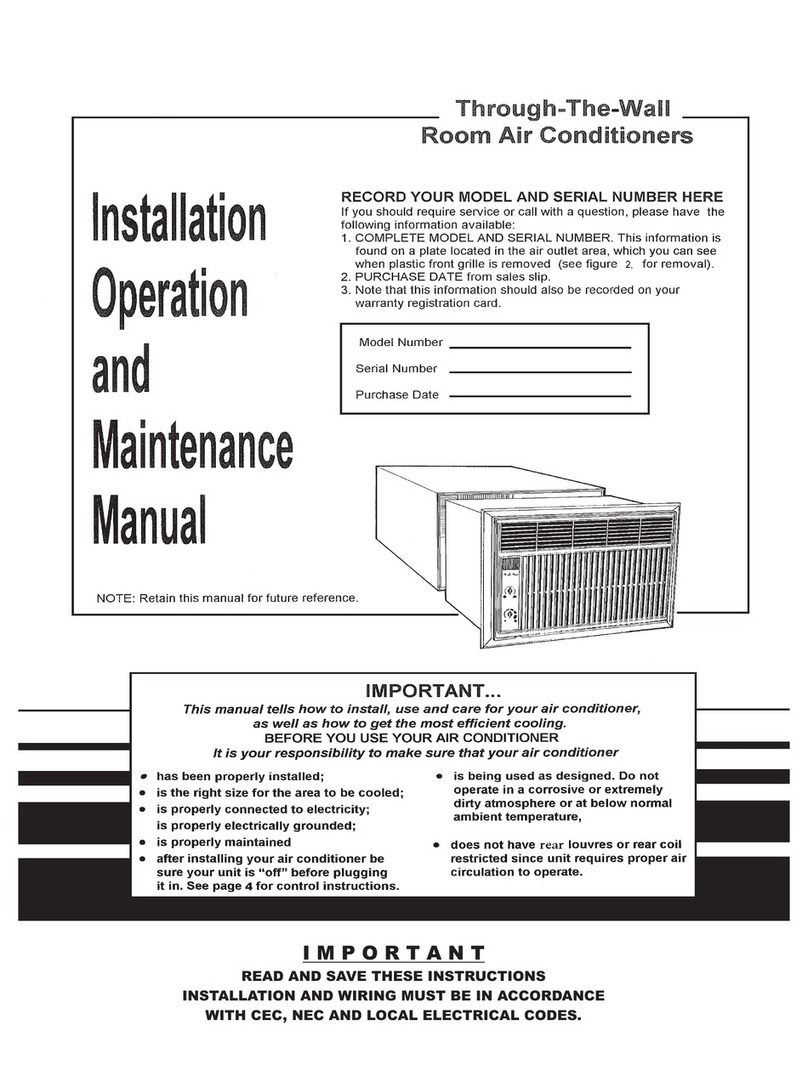

CHASSIS INSTALLATION

1. Unpack heat/cool chassis from shipping carton. Check for

any shipping damage.

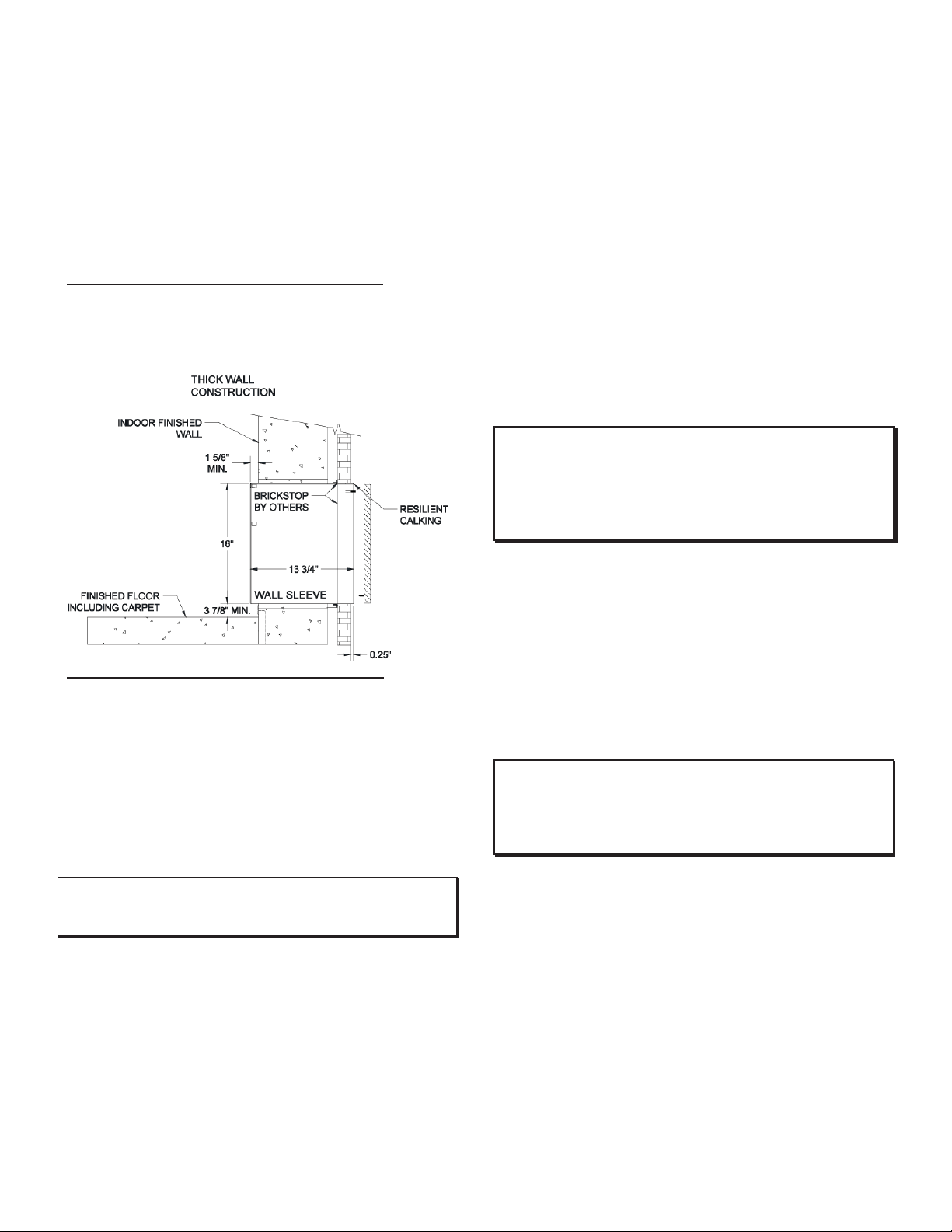

2. The chassis must be level from side-to-side and from front-

to-rear, once the chassis side flanges are drawn up tight to

the wall sleeve using the four flange screws. This can only

be achieved if the wall sleeve was installed level in all

directions, which they should have been according to the

Original Equipment Manufacturer’s instructions. If the

sleeves were originally installed with a slight slope in the

order of ¼” per foot downward from the indoor to outdoor

side, the chassis will still function properly, but the indoor

drain kit option will not work properly with it. A slope

downward from outdoor-to-indoor side is not permissible

and must be corrected before the unit is operated.

3. There are vertical air seals at the rear of the unit that

surround the condenser outlet that will engage and “seal”

against the rear grille. However, in some cases, such as

when an extra deep wall sleeve is used, or some other

variation is encountered that prevents the air deflectors

from sealing against the outdoor grille, then steps must be

taken to add anti-recirculation baffles to prevent hot

condenser air from short-circuiting back into the air intake

via the void space created in behind the outdoor grill.

4. Position the chassis in the cabinet and slide into place.

Keep the chassis level and square to prevent binding. The

chassis must be pushed into the wall sleeve until the side

flange seals of the chassis engage the sleeve. Alternately

tighten each of the four draw screws until the chassis is

drawn snugly into the sleeve. Do not over-tighten the draw

screws.

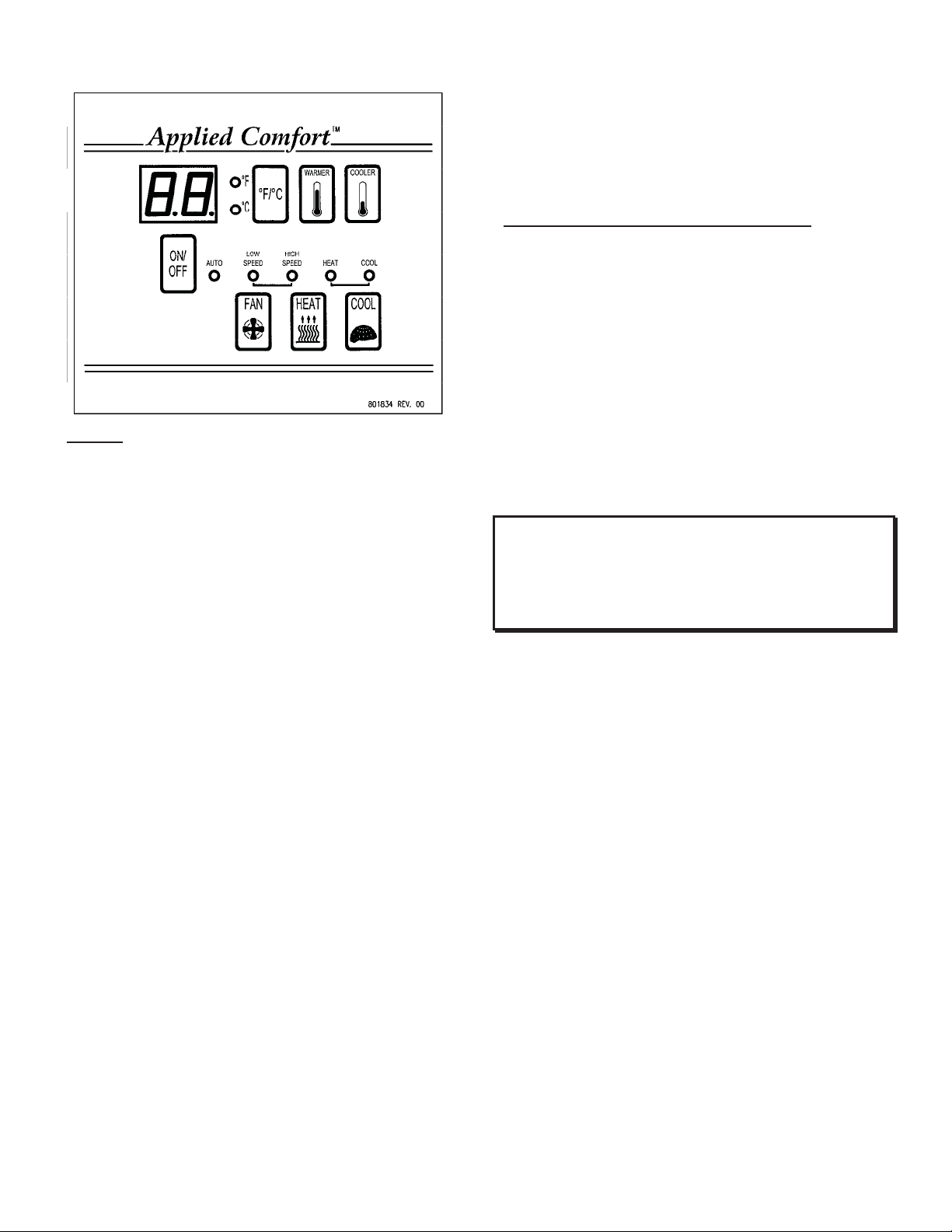

5. If the unit is equipped with electronic controls and

touchpad, locate the 24 Volt wiring harness coiled beneath

the control box. The harness is employed if in one or both

of these situations exist; one, if a remote 24 Volt AC wall

thermostat will be used, and two, if a 24 Volt AC aquastat

will be used. If either of these situations exist, connect the

multi-wire 24 volt wiring harness to the mating plug

protruding beneath the control box, as applicable,

following the detailed instructions on the wiring diagram

affixed to the specific unit being installed. Insulated crimp-

on connectors are provided at the end of every connection

lead to facilitate connections/insulation. If an aquastat

will be not be used, connect the ends (blue/orange) of

the aquastat leads together to permanently complete

the aquastat circuit.

6. If the unit is equipped with mechanical knob controls and

touchpad, this variation cannot be adapted to work with a

remote thermostat. Locate the 24 VAC aquatsat output

connector beneath the control box. A mating connector and

6 feet of wire leads are supplied to connect to an aquastat

switch if desired. The leads can be shortened as required. If

an aquastat will not be used, connect the ends

(orange/orange) of the aquastat leads together with a

field-supplied insulated connector to permanently

complete the aquastat circuit.

7. For all control variations, two 24 VAC hydronic valve

output connectors are provided – one under the control

box, and one at the bottom of the left side panel. A mating

connector and 2 feet of wire leads are supplied to connect

to a 24 VAC hydronic valve. The units can accommodate a

normally-open NO or a normally-closed NC hydronic

valve.

NO or NC is selected by a switch. The NO/NC switch is

located on the bottom front edge of the control box for

mechanical knob control units and is accessible to the user

once the room enclosure front panel is removed.

The NO/NC switch is located in the high voltage wiring

compartment as a DIP switch on the electronic control

equipped units, and is factory set to NO. The setting can be

changed to NC in the field, but only by qualified service

personnel.

WARNING: The NO/NC conversion procedure involves

exposure to high voltage electrical circuits in the control box

in order to make the necessary change to the DIP switch, and

must be performed by qualified service personnel. Failure to

do so could result in property damage, personal injury or

death. Disconnect electric power to the unit before servicing.

8. Plug the heat/cool chassis cord into the power receptacle

located either in the subbase or the wall, as applicable.

9. Install the front panel and secure it with the two retaining

screws located in its bottom corners.

WARNING: Operating the unit without the filter in place

can not only damage the unit, but also expose the user to a

hazard from rotating parts, potentially resulting in bodily

injury. The filter is intended to be removable only with the

use of a tool. Always remember to re-install the filter and

filter retaining clip after servicing the chassis, or

replacing/cleaning the filters.

10. Wipe unit cabinet/wall sleeve to remove dirt, etc.

11. The unit is now ready for operation, when supplied with

power from the distribution panel and wired to a remote

thermostat (if applicable).