2

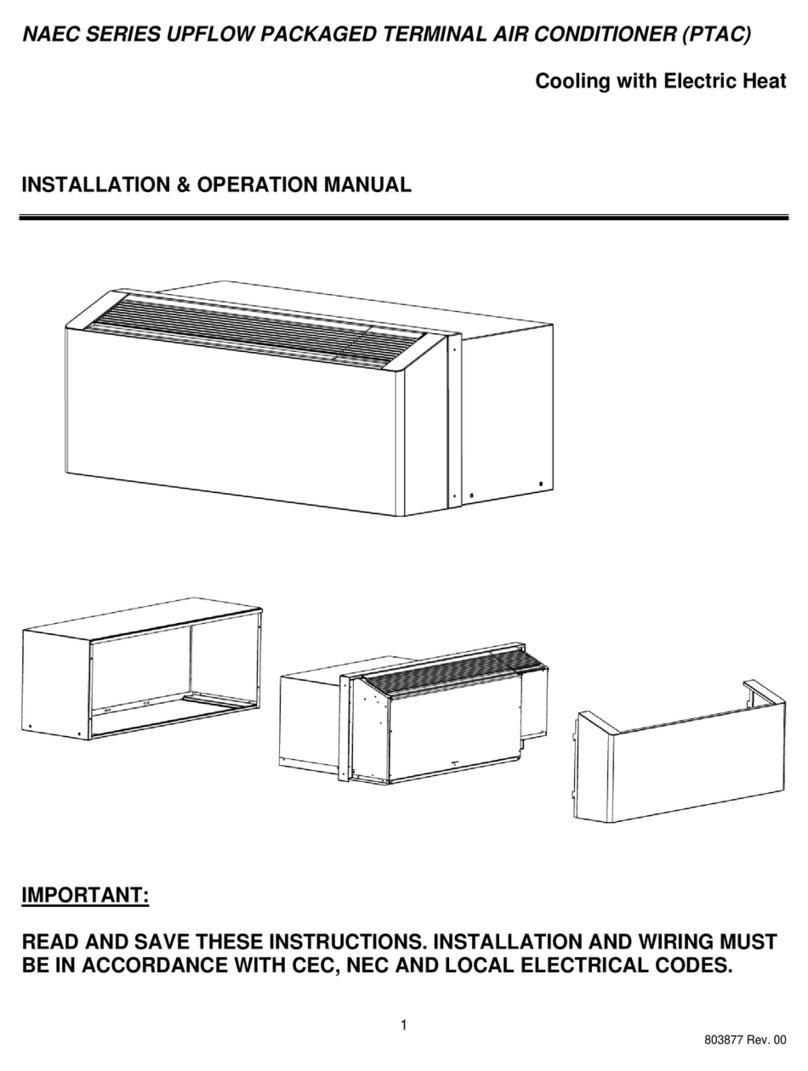

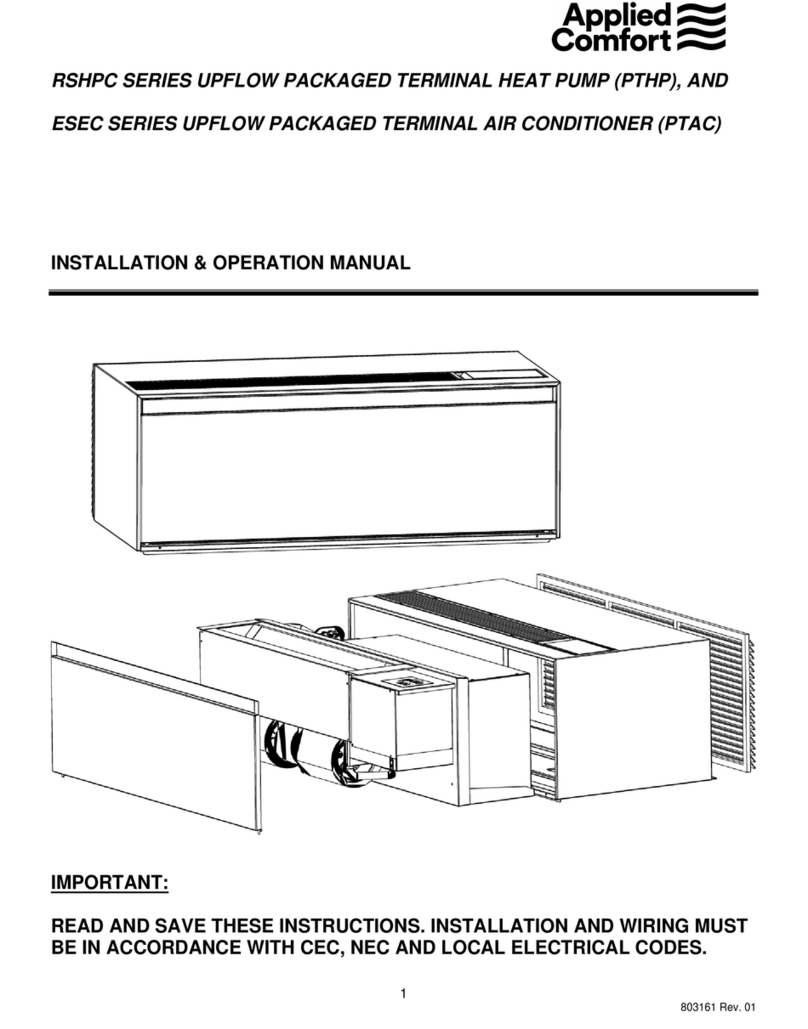

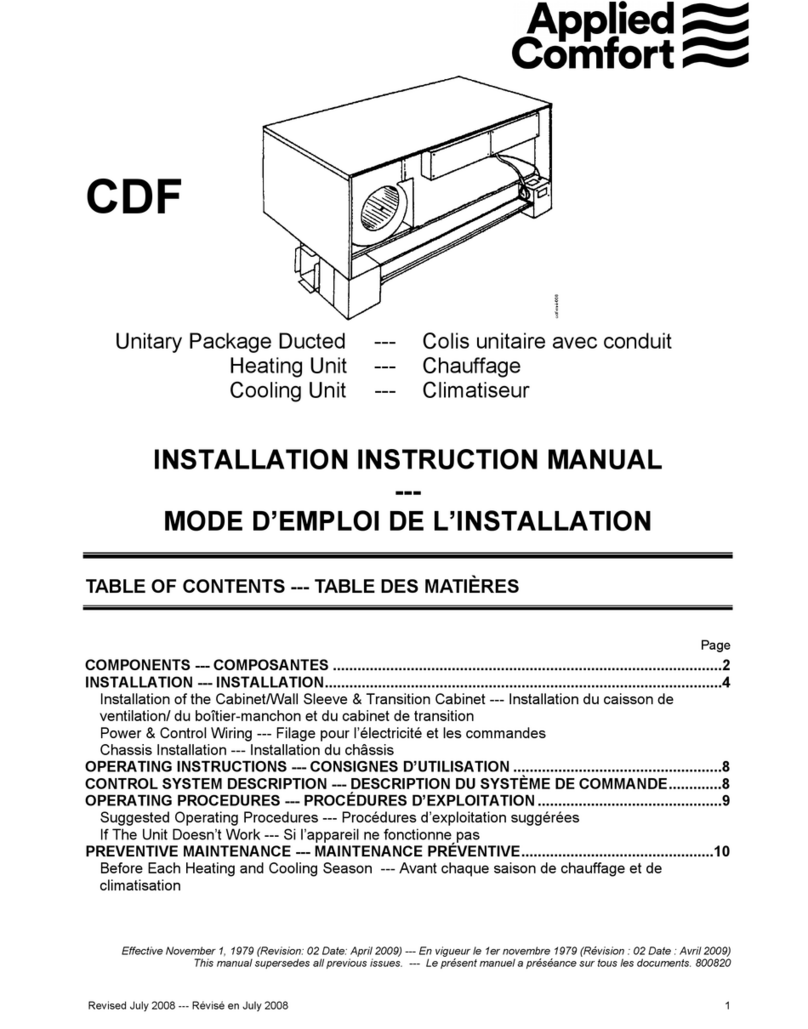

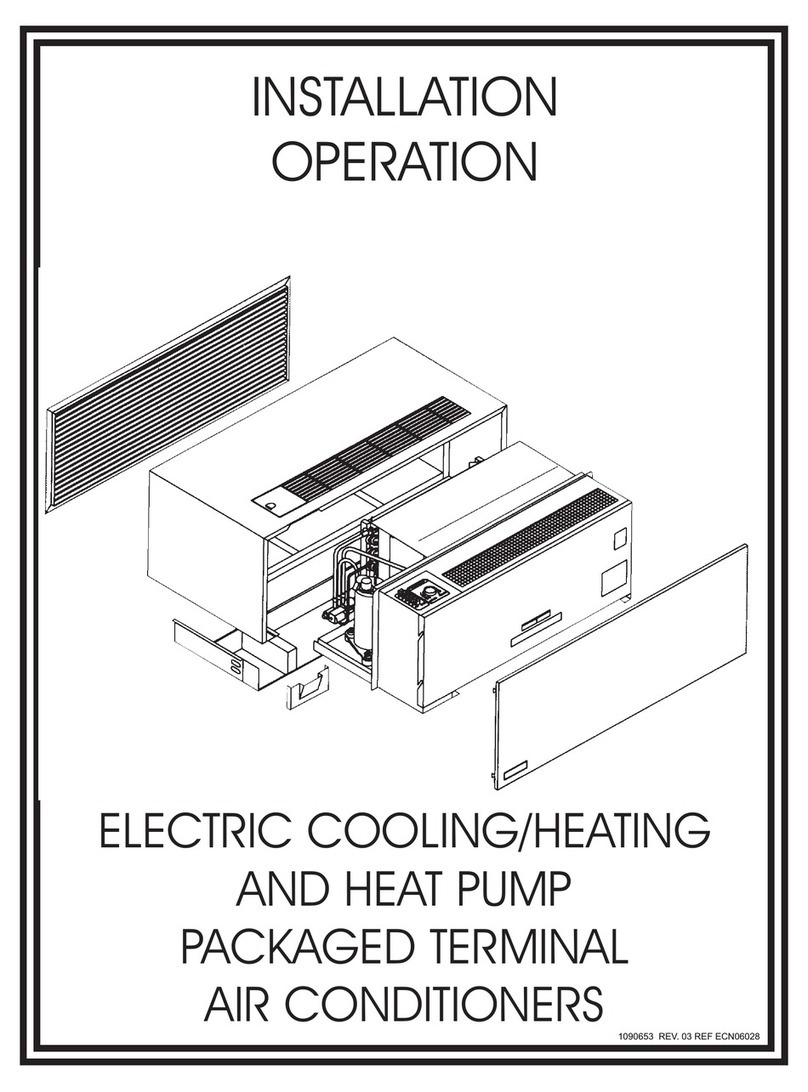

COMPONENTS

1. Wall Sleeve & Outdoor

Grille

The wall sleeve is to be built into

the wall during construction. The

wall sleeve is used for all wall

thicknesses from 2” through 13”

maximum. For a 13” deep wall the

outdoor louvers will have to be

mounted flush with the outside wall

surface. For walls thicker than 13”,

a cabinet extension is required.

For installation of wall sleeve

extensions, see instructions

packed with the extensions.

The wall sleeve must penetrate

into the room by a fixed distance in

order for the downflow room

cabinet apparatus to function

properly. Therefore set the sleeve

in the wall so that 1” of the sleeve

protrudes into the room. This is

necessary in order to obtain the

10” distance between the front

panel and the inside wall face as

shown in Figures 1 and 2, once the

plenum and side ducts are added.

After installation of the wall sleeve,

the sleeve should be thoroughly

cleaned. The room-side portion of

the cabinet should be carefully

protected during the construction

period to prevent scratching of the

paint.

IMPORTANT:

The heating/cooling unit must not

be used for temporary heating or

cooling during the building’s

construction stage.

2. Heating/Cooling Chassis

This chassis includes all cooling

components, air moving

components and controls, except

for the 24-volt room thermostat.

3. Power Supply Cord & Plug

A power supply cord with 30 Amp

or 50 Amp male plugs (as

applicable) extends from the left

side of the control section located

on the right hand side of the unit.

This cord is to be attached to a

field – supplied receptacle

mounted in the factory – supplied

junction box mounted in the sub

base located under the unit. The

sub base is sized to fill the gap

between the finished floor and the

room cabinet when the wall sleeve

is installed 4” above the finished

floor as shown in Figure 1.

If the maximum fuse or circuit

breaker listed on the unit rating

plate is 30.0 Amps or less, then a

NEMA 6-30R receptacle is used. If

the marked maximum fuse or

circuit breaker rating exceeds 30.0

Amps, then a NEMA 6-50R

receptacle must be used. The

cover plate is supplied with the sub

base.

4. Plenum / Vertical Ducts

The plenum is a horizontal duct

that attaches by screws to the top

panel of the chassis, once the

chassis is fully inserted and drawn

up tightly in the wall sleeve. The

plenum collects the air as it exits

from the top of the chassis, and

turns the air in a right hand and left

hand direction. When the air

reaches the ends of the plenum, it

is directed downward into the

vertical side ducts where it flows

toward the floor. Air duct outlet

collars are provided on the side

ducts.

The left and right vertical side ducts

are fully insulated and connect to

the underside of the plenum using

the sheet metal screws provided.

Ensure the duct collars on the side

ducts are facing away from the

chassis so air will be directed out

the left and right sides of the room

enclosure apparatus.

5. Ducting

The vertical side ducts come

complete with a duct collar on the

lower outboard side, to accept 6”

wide by 8” high lateral flanking

duct. The unit must be ducted out

both sides. The interior of the

flanking duct must be insulated

with a minimum of ½” thick

fiberglass duct liner, suitable for the

air velocities involved. The outlet

vents should be located on the top

of the distribution ductwork facing

up.

6. Duct Sizing

The ducts must be sized for a

maximum pressure drop of 0.20” of

water column at 400 CFM total

airflow directed out both sides of

the unit. This will ensure that

adequate airflow will result when

the unit is operating at the factory –

set indoor blower speeds for the

particular heating and cooling

capacity of the unit. There is no

minimum pressure drop so large or

short ducts are not a problem.

Size the duct for the anticipated

fraction of 400 CFM pertaining to

that branch. In other words, if 40%

airflow is desired out of the left side

and 60% out the left, then size the

duct as follows:

40/100 X 400 = 160 CFM at .20”

w.c. maximum, out the right side.

60/100 X 400 = 240 CFM at .20”

w.c. maximum, out the left side.

Or, design both ducts for 240 CFM

at .2” w.c. maximum and use

dampers or the right side outlet

grilles to throttle the flow down to

160 CFM in the right side branch.

The .20” w.c. pressure drop should

also include the air resistance

through the outlet vents calculated

at the predicted CFM exiting out

each vent.