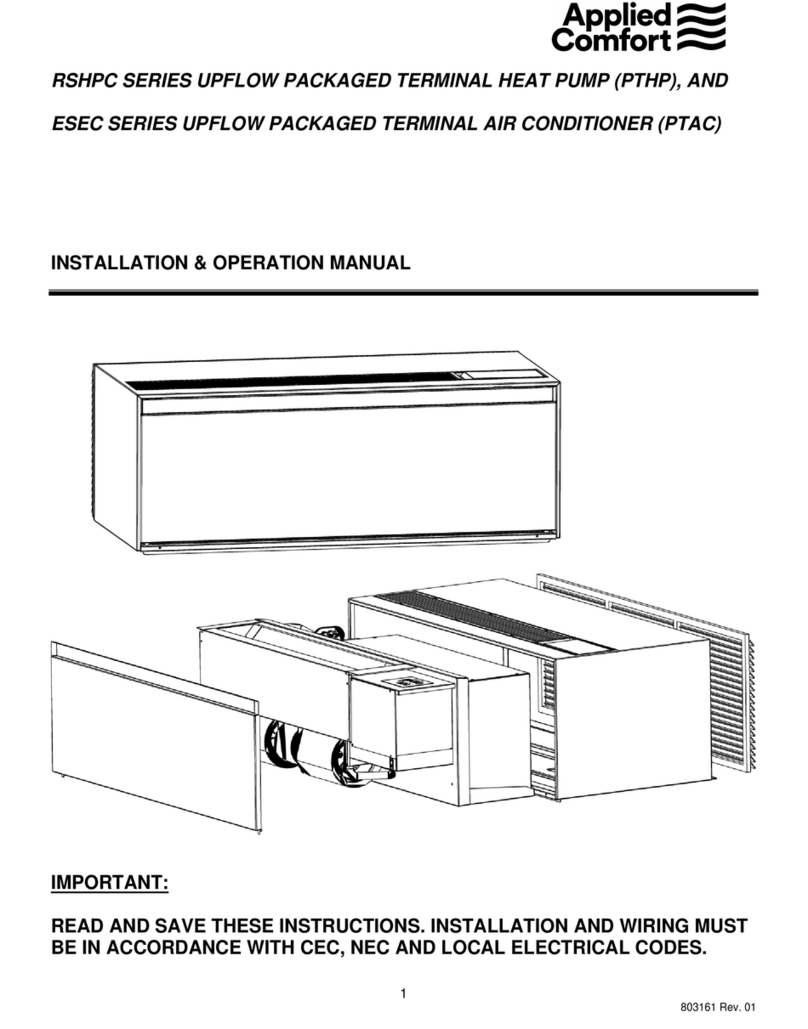

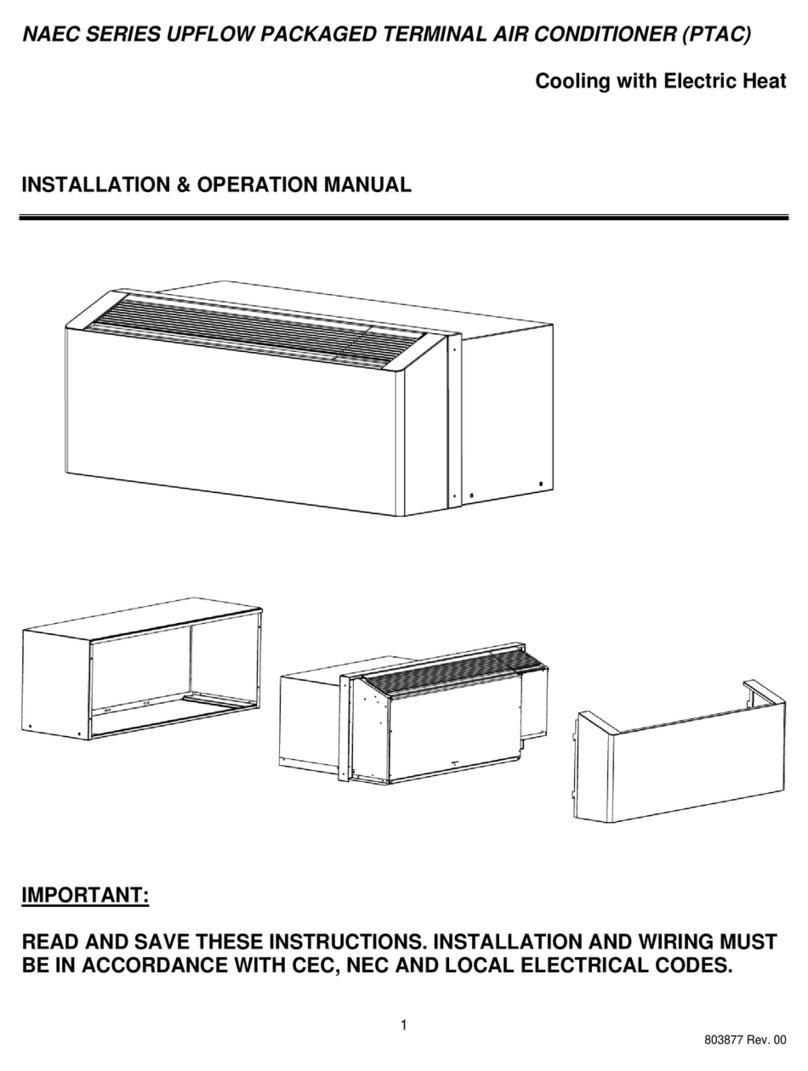

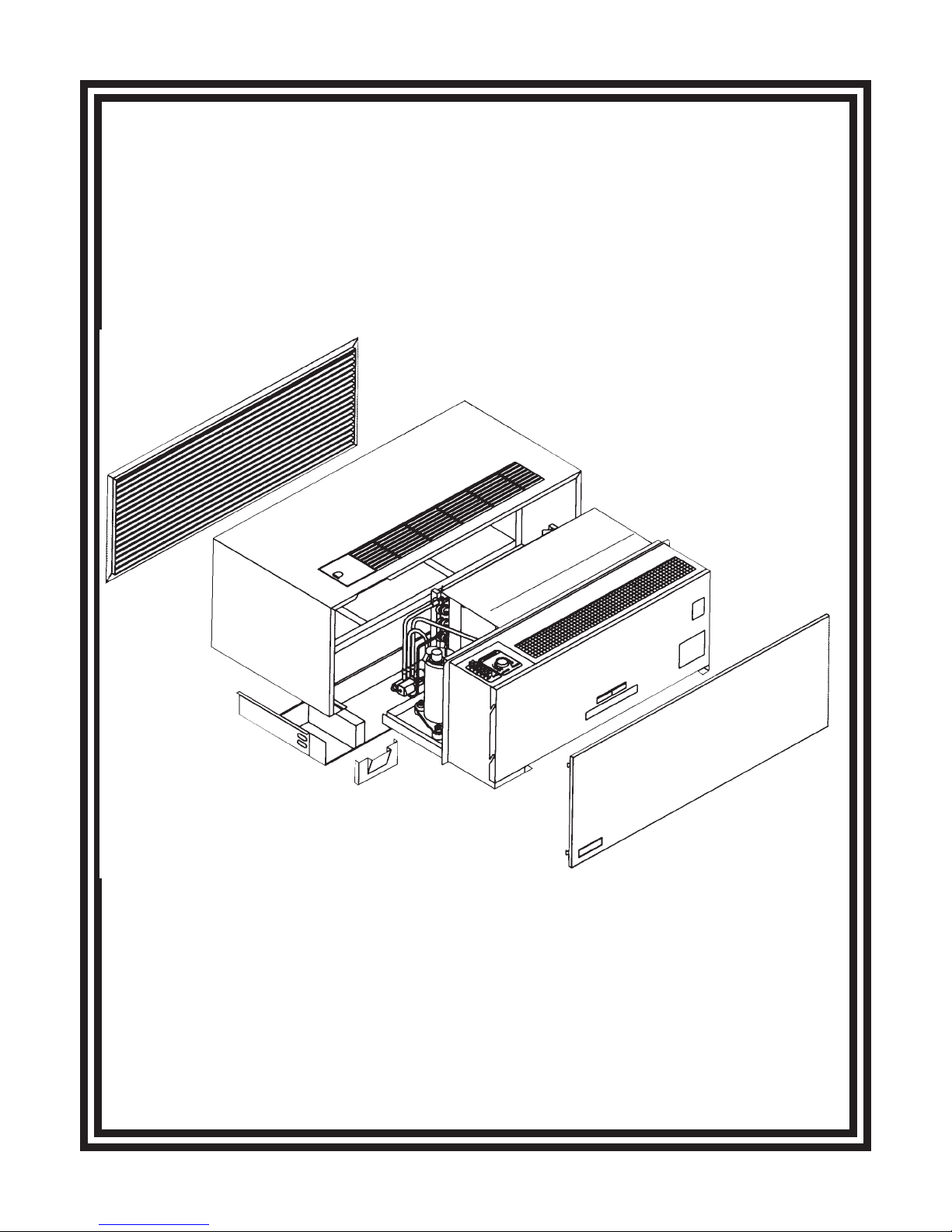

General Information

DO NOT INSTALL CHASSIS INTO SLEEVE WITHOUT FIRST

READING CHASSIS INSTALLATION PROCEDURE.

RECOMMENDATIONS FOR

EFFICIENT OPERATION

·

·

Keep air intake filter clean. Units are provided with a

washable filter that can be cleaned with soap and water

(we recommend monthly). IMPROPERLY

MAINTAINED FILTER OR NOT USING A FILTER WILL

VOID COMPRESSOR WARRANTY.

Don’t block off the outside air flow to the unit. Paper or

other material on the outside of the unit can impair

efficiency and cause serious damage to the compressor.

·

·

·

When unit has been turned OFF, wait three minutes

before re-energizing unit.

In case of power interruption, it is recommended that

the unit be turned “OFF” until power has been restored

for three minutes. (Operation of the air conditioner with

low voltage input can cause serious damage.)

Clean unit coil and oil motors annually. Some motors

are permanently lubricated and do not require annual

oiling.

To avoid property damage, bodily injury or death, ensure power is disconnected before any service is attempted.

Repairs should be made by a qualified air conditioner service technician only.

DANGER

UNIT OPERATION

(For Units Equipped with Heating Option)

THERMOSTAT OPERATION WHEN STARTING:

Set the dial in the mid position to begin operation. After

several hours of operation adjust to desired comfort

setting. No further adjustment is necessary. Your unit

will bring the room back to the desired temperature each

time you turn the unit on.

ADJUSTING DURING OPERATION:

Move the dial a small amount at a time in the direction

you wish the temperature to go. Moving the dial more

than 1/8 inch at a time may overcompensate and lead to

an extreme hot or cold situation.

EMERGENCY HEAT OPERATION

(Heat Pump Units Only)

In the unlikely event of a compressor failure, the electric

heater can be manually energized.

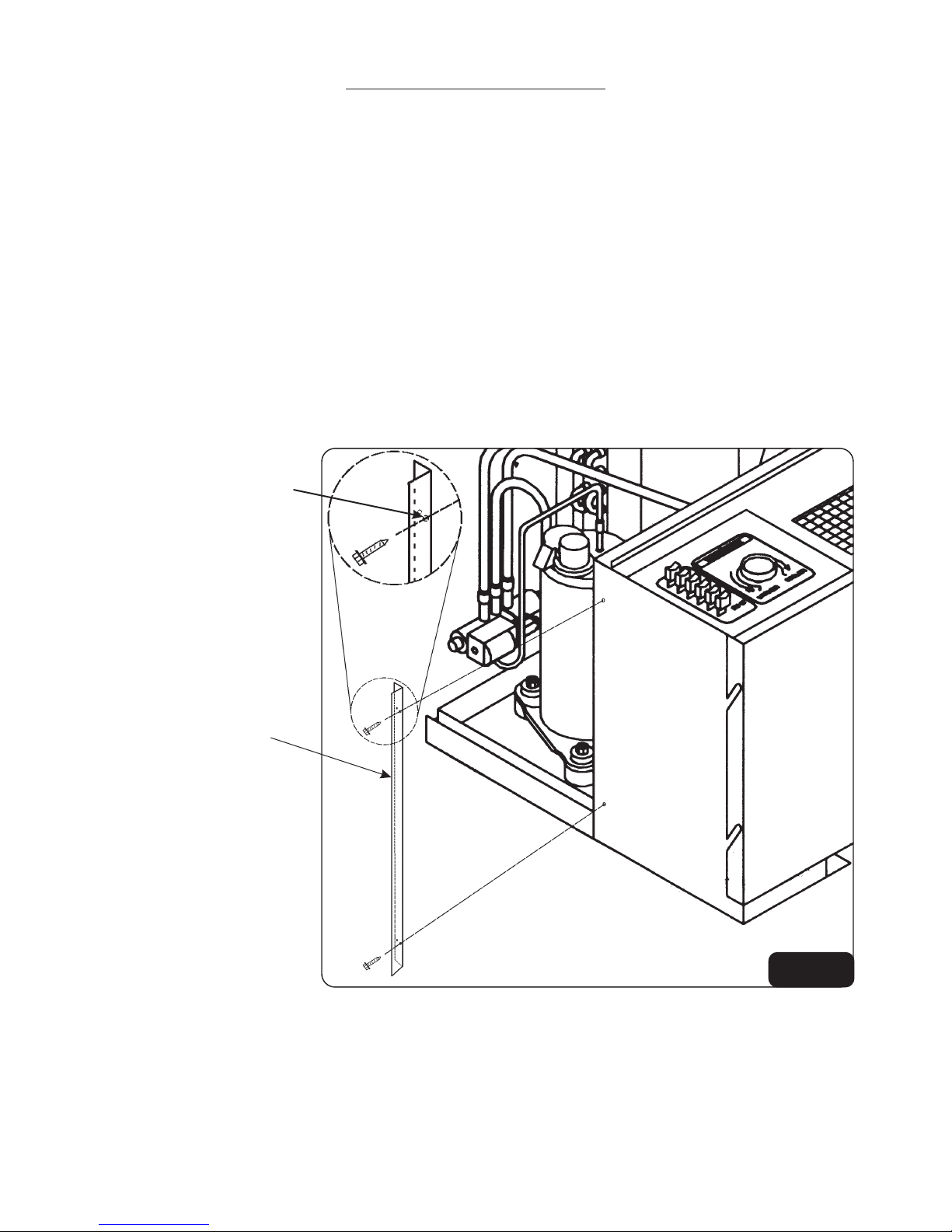

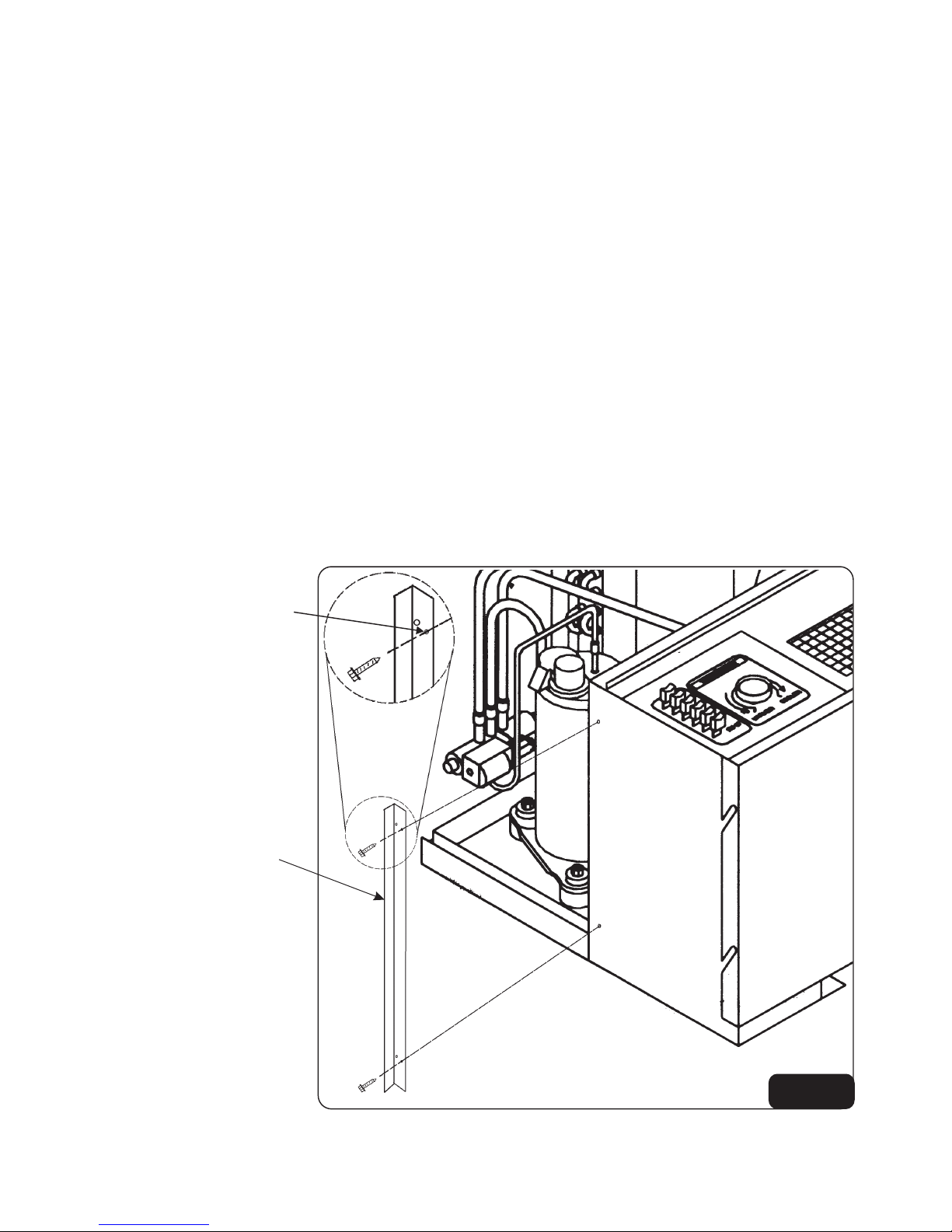

By removing the front panel of sleeve cabinet, you will

find a manual emergency heat switch located on the

lower left side of the chassis in the excess cable storage

area. The switch is marked and

. By moving the switch to

the resistance heat will come on providing the

push-button switch is in the mode. See Figure

12, page 10.

The temperature is controlled through the thermostat.

Remember to turn switch to when the unit

has been repaired.

“EMERGENCY HEAT”

“NORMAL” “EMERGENCY

HEAT”

“HEAT”

“NORMAL”

UNITS WITH LOW TEMPERATURE

THERMOSTAT

Some units may be equipped with a low temperature

thermostat.

This option energizes the fan and electric heater

whenever the room temperature approaches freezing

conditions, regardless of the push-button switch setting.

GENERAL

Temperature control is automatic once you have

selected desired mode of heat or cool and the

temperature you wish to maintain in the room. No further

adjustments are necessary for your comfort control.

The heat pump heating cycle will automatically switch

from heat pump mode to electric resistance heat when

outdoor ambient temperature drops below the design

temperature of the unit.

The buttons on the control panel determine the mode

(heat or cool) and the thermostat pointer on the control

panel determines the room temperature.

2