Installation and Service Manual – Metered Carbon Filter

Page 3

Copyright © 2012 Applied Membranes, Inc. All Rights Reserved.

TableofContents

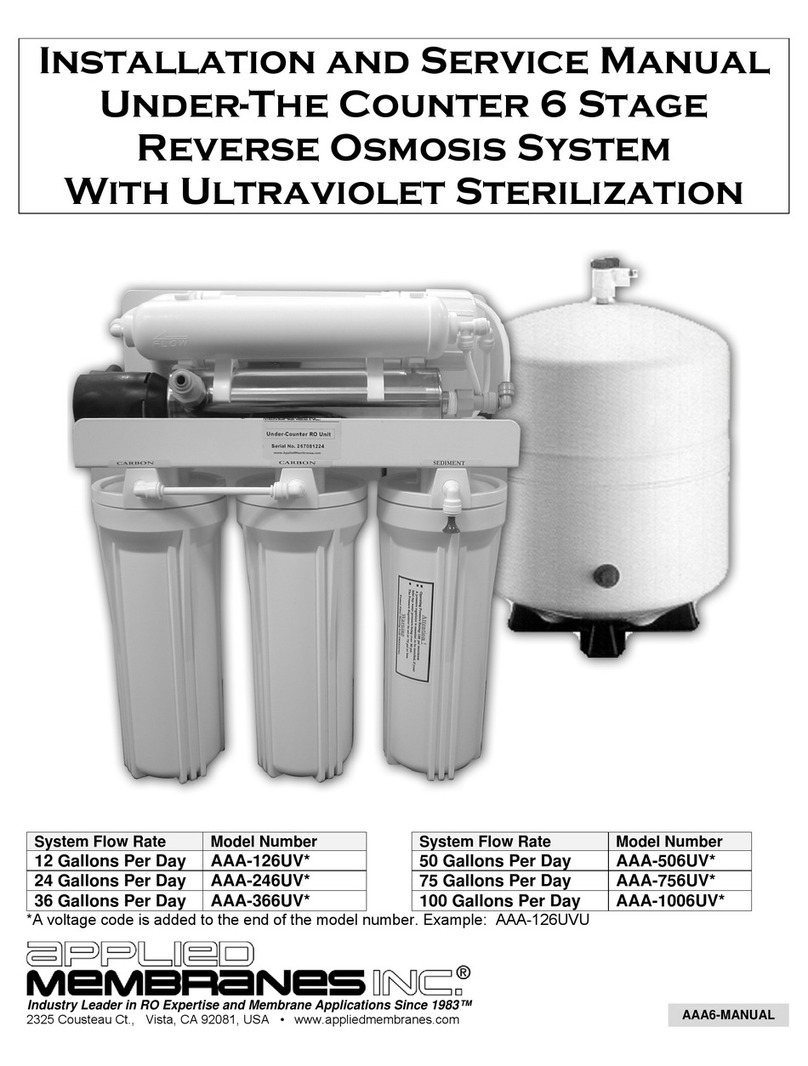

Design Basis & Specifications.............................................................................................................................................4

General Information and Safety...........................................................................................................................................4

Installation .............................................................................................................................................................................4

Location...............................................................................................................................................................................4

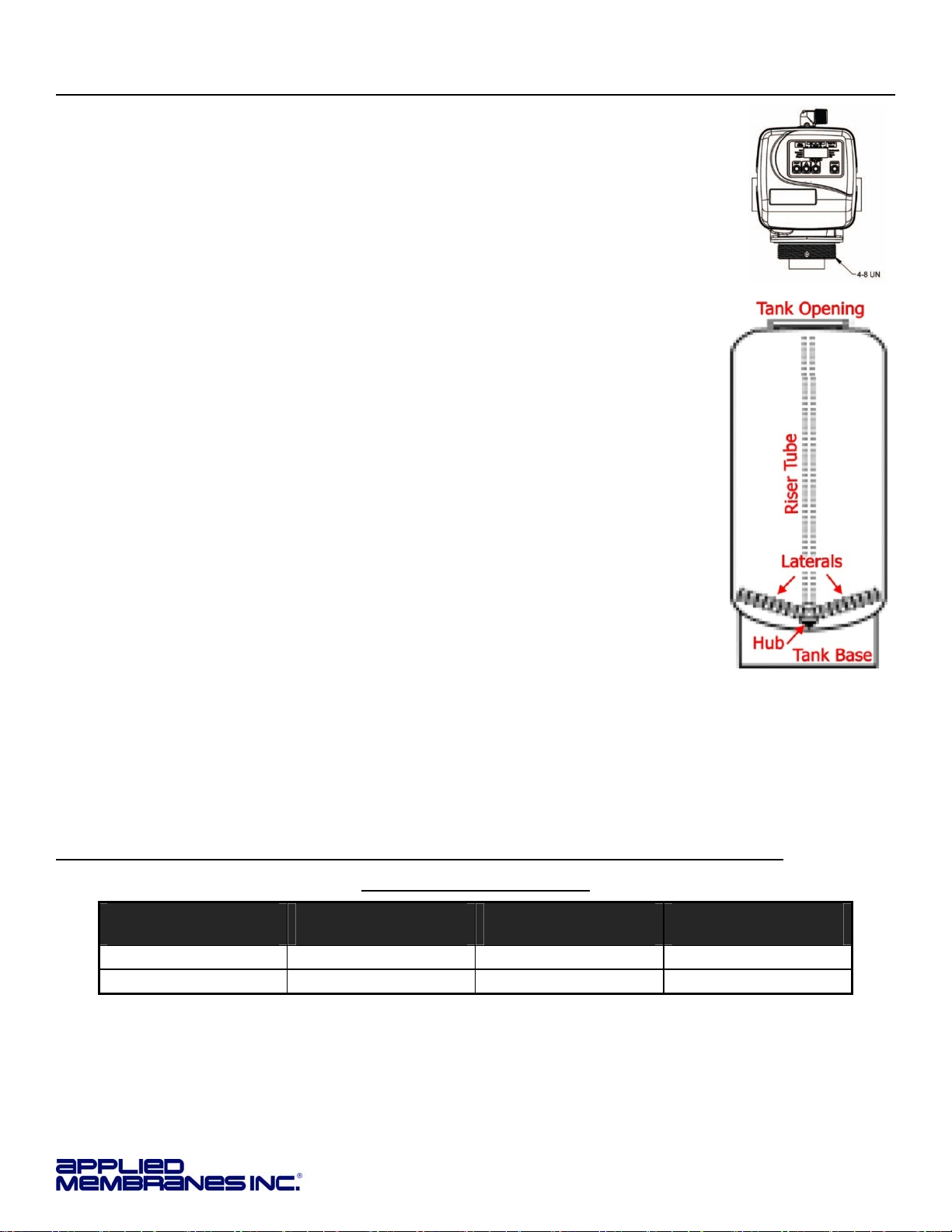

Loading the Media...............................................................................................................................................................5

MediaQuantity per Model ....................................................................................................................................................5

Plumbing..............................................................................................................................................................................6

Operating Do’s and Don’ts...................................................................................................................................................7

Initial Start-Up........................................................................................................................................................................8

System Monitoring and Record Keeping............................................................................................................................8

Operating Conditions ...........................................................................................................................................................8

Control Valve Operation & Service .....................................................................................................................................9

Control Valve Specifications................................................................................................................................................9

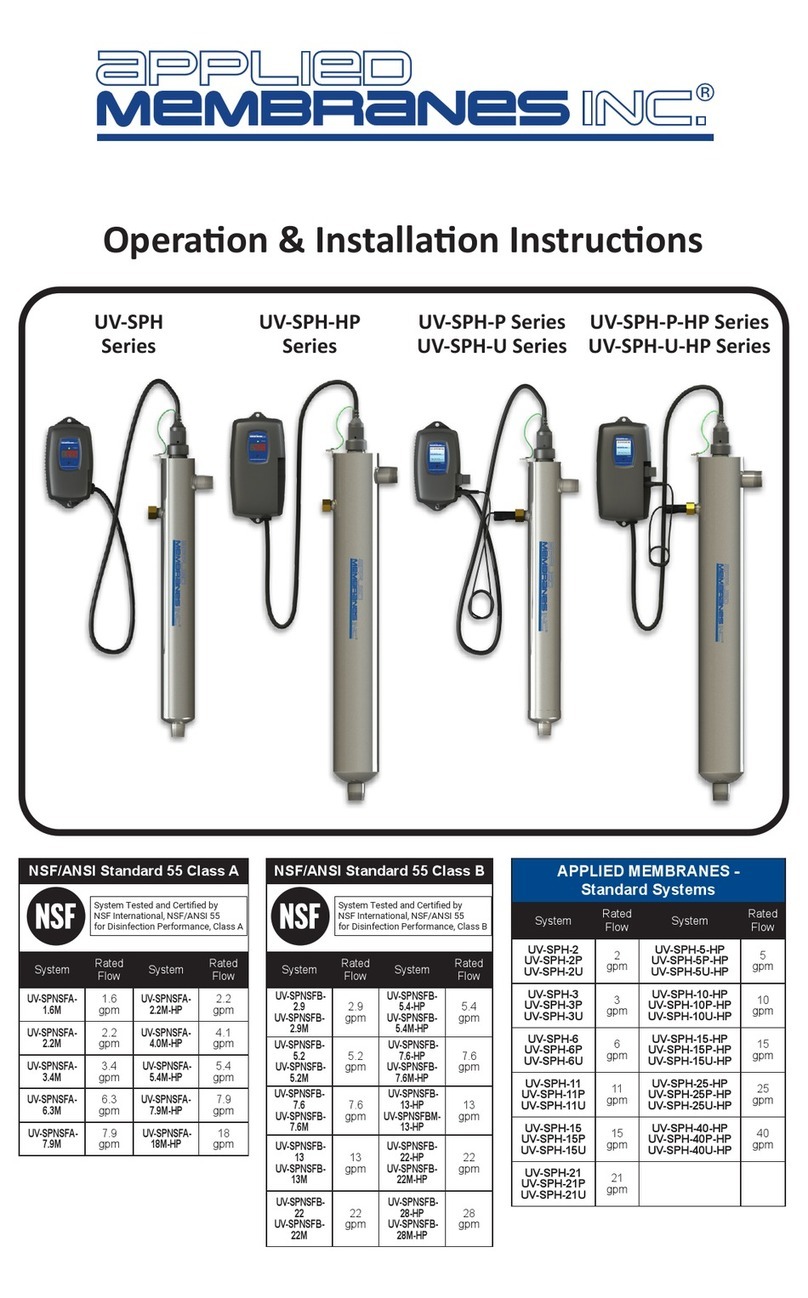

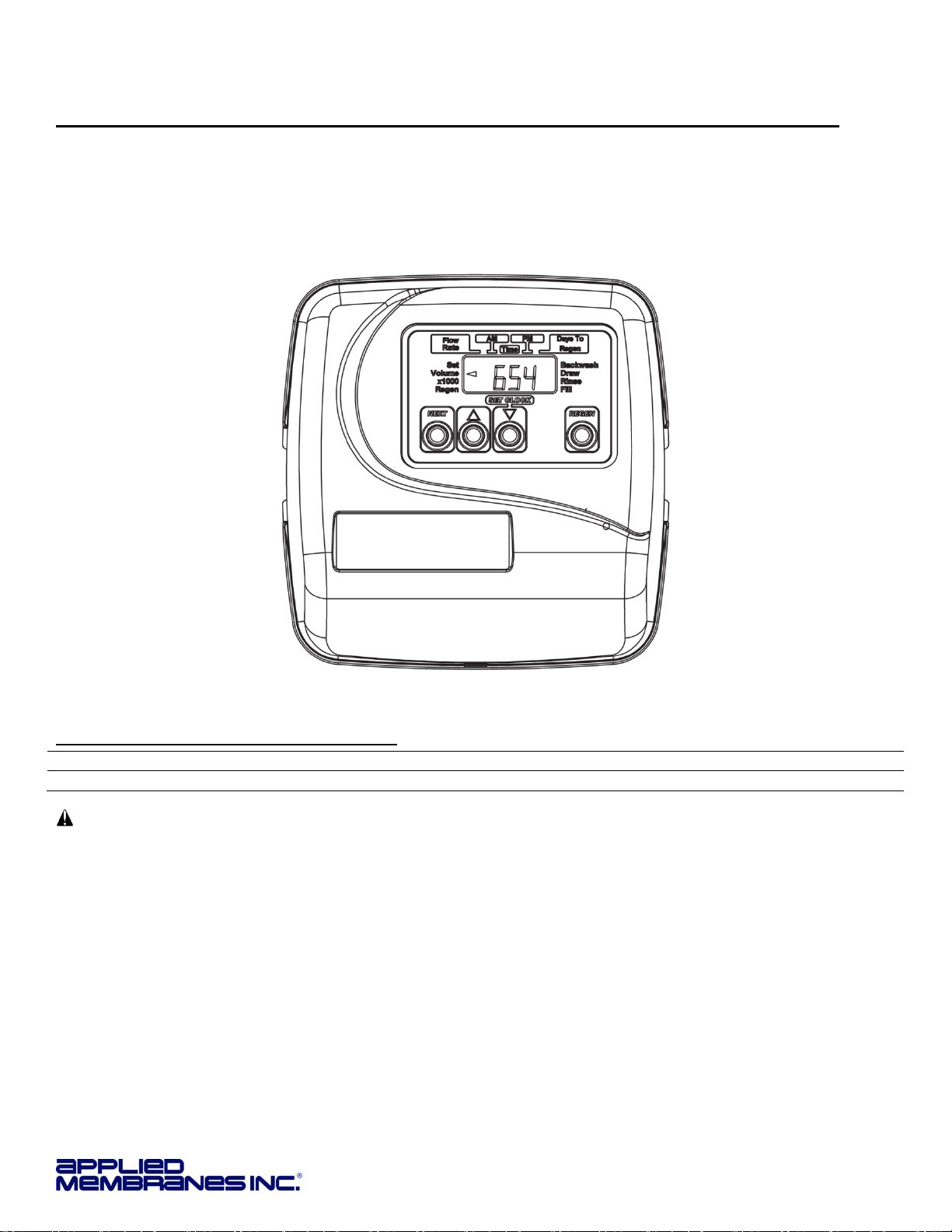

User Display ......................................................................................................................................................................10

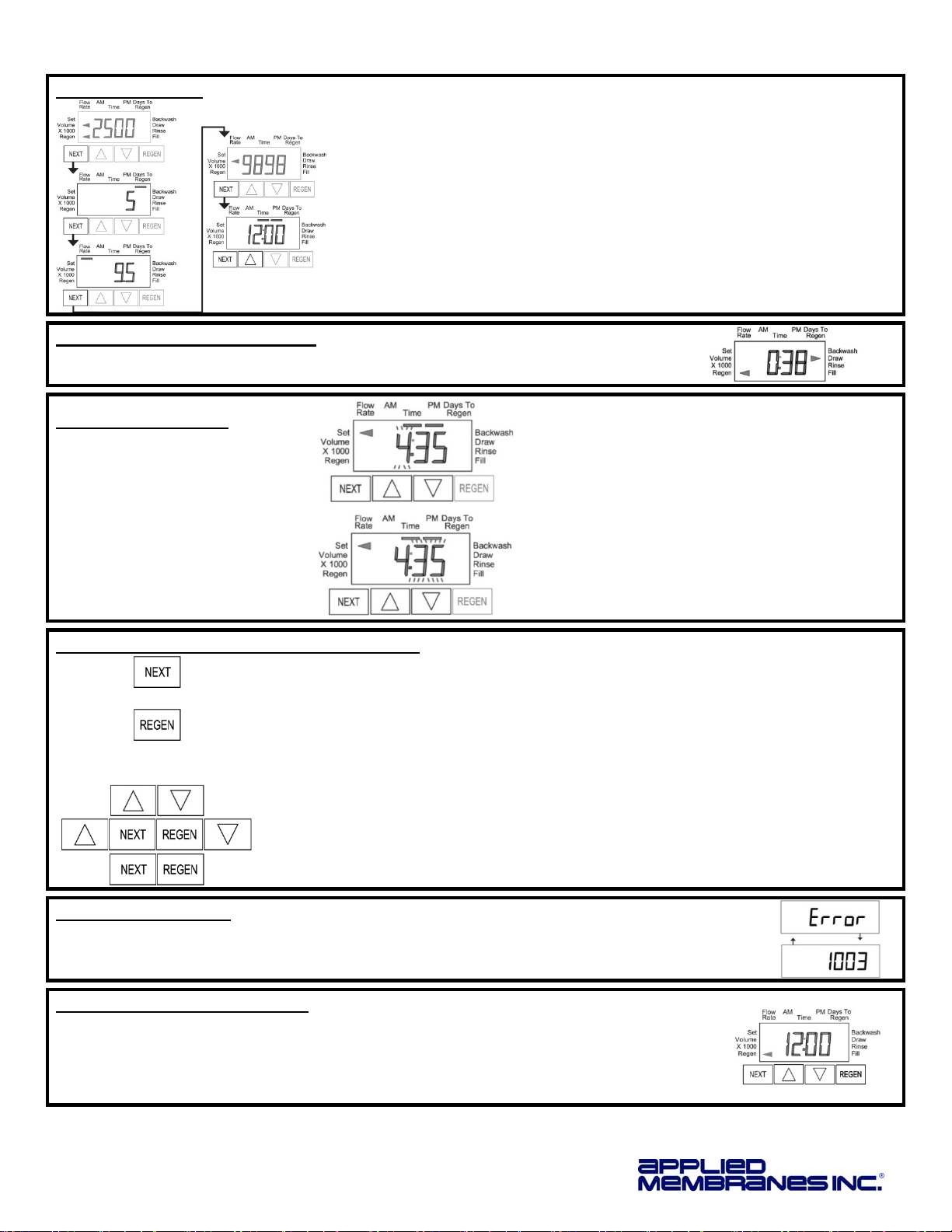

Regeneration Screens.......................................................................................................................................................10

Set Time of Day.................................................................................................................................................................10

Button Operation and Function .........................................................................................................................................10

Error Message...................................................................................................................................................................10

Manual Regeneration........................................................................................................................................................10

General Warnings & Site Requirements ...........................................................................................................................11

Control Valve General Features and Information..............................................................................................................11

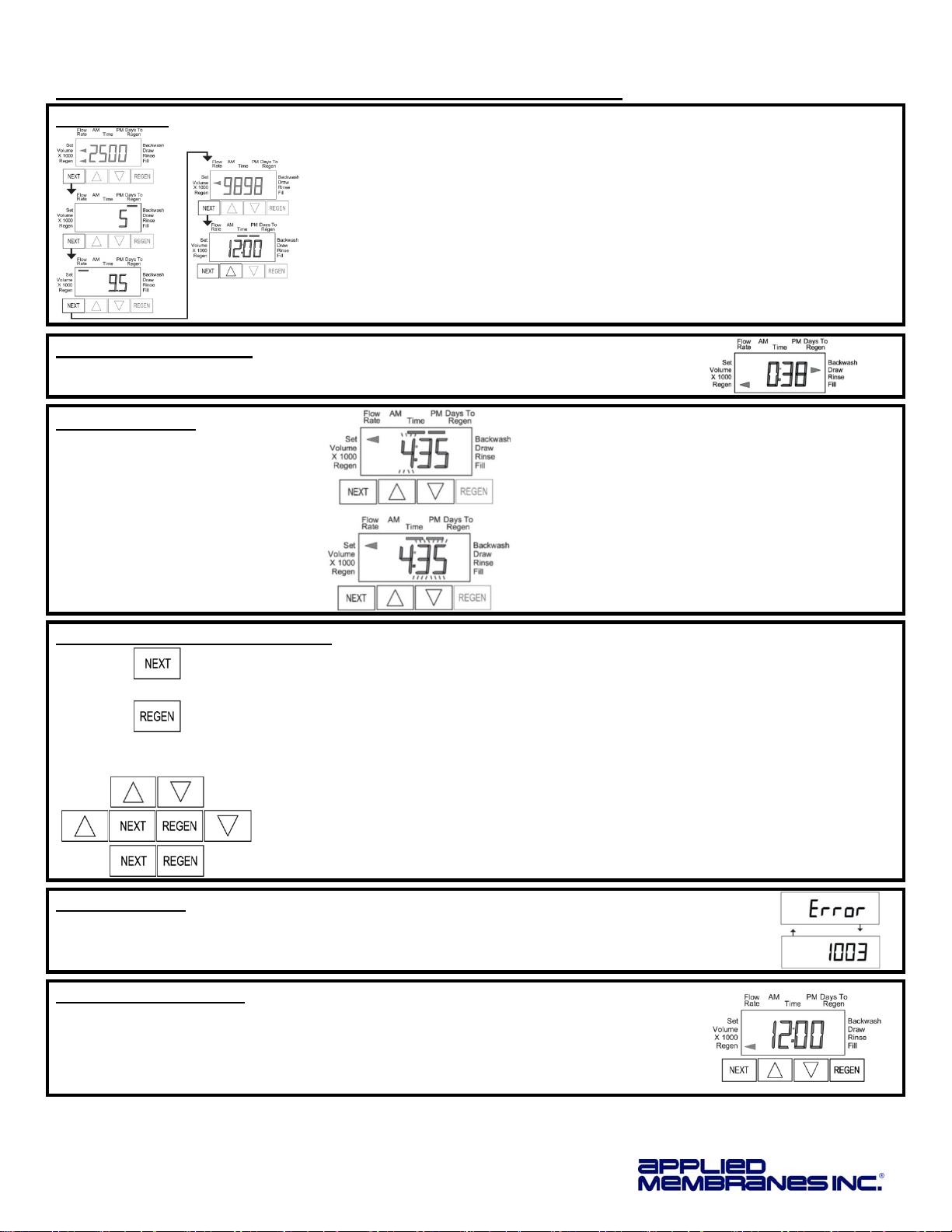

Configuring and Programming Control Valve Options...................................................................................................11

Metered Backwash Filter Recommended Programming Overview...................................................................................12

Configuration Settings (Pre-Programmed to Factory Defaults).......................................................................................13

Regeneration Cycle Time Settings (Pre-Programmed to Factory Defaults)..................................................................14

Installer Displays and Settings for Control Valve Options.................................................................................................15

Diagnostics........................................................................................................................................................................17

Control Valve Drawings and Components.......................................................................................................................18

CV1.5 Overview Drawings.................................................................................................................................................18

CV1.5 Drive Cap Assembly, Downflow Piston, Regenerate Piston & Spacer Stack Assembly ......................................19

CV1.5 Injector Valve Body, Refill Flow Control and Injector Plug.....................................................................................20

CV1.5 Drain Line Flow Controls........................................................................................................................................21

Meter Assembly.................................................................................................................................................................22

CV1.5 Flow Diagram, Service ...........................................................................................................................................23

CV1.5 Flow Diagram, Backwash.......................................................................................................................................23

CV1.5 Flow Diagram, Rinse..............................................................................................................................................24

Service Spanner Wrench...................................................................................................................................................24

Control Valve Service Instructions ...................................................................................................................................25

Drive Assembly..................................................................................................................................................................25

Drive Cap Assembly..........................................................................................................................................................26

Main Piston........................................................................................................................................................................26

Spacer Stack Assembly.....................................................................................................................................................27

Injector Cap, Screen, and Injector Plug.............................................................................................................................27

Refill Port Plug...................................................................................................................................................................27

Drain Line Flow Control.....................................................................................................................................................27

Meter Assembly Service Instructions ................................................................................................................................27

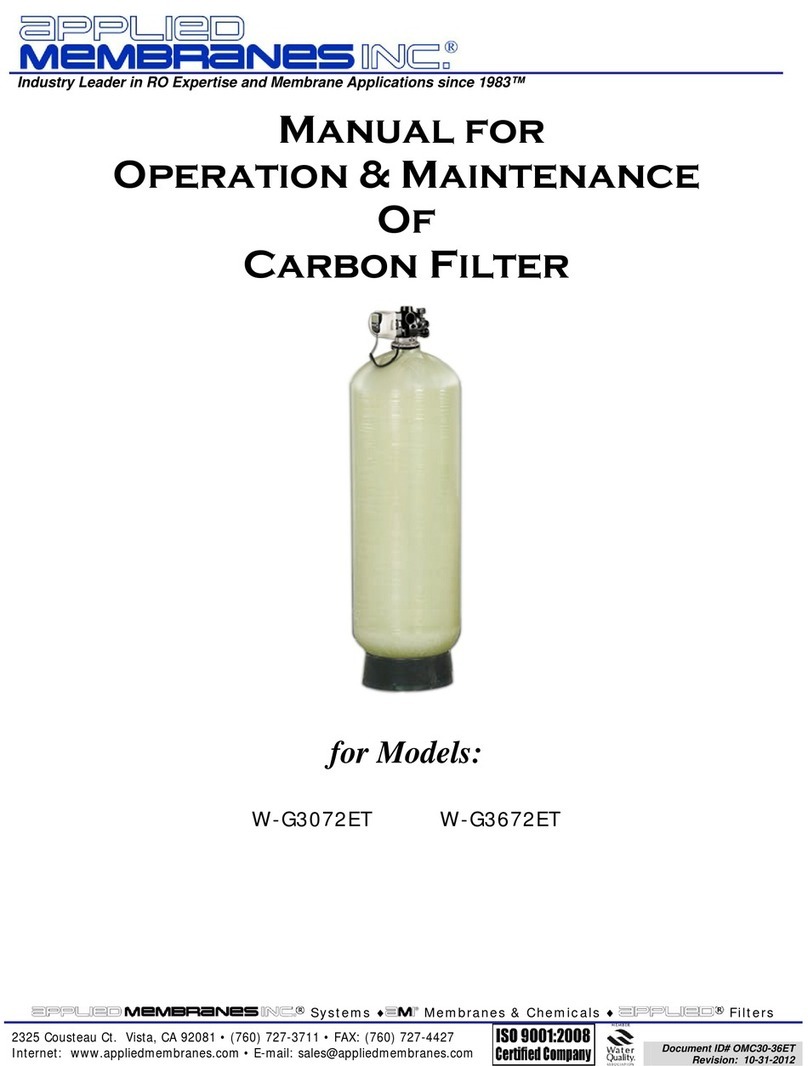

Maintenance – Removal & Replacement of Carbon Media.............................................................................................28

Troubleshooting..................................................................................................................................................................29

Product Warranty................................................................................................................................................................32