Applied Membranes AAA-126UV Series Manual

Other Applied Membranes Water Filtration System manuals

Applied Membranes

Applied Membranes W-G3072ET Manual

Applied Membranes

Applied Membranes AAA-125P Owner's manual

Applied Membranes

Applied Membranes W-G844EM User manual

Applied Membranes

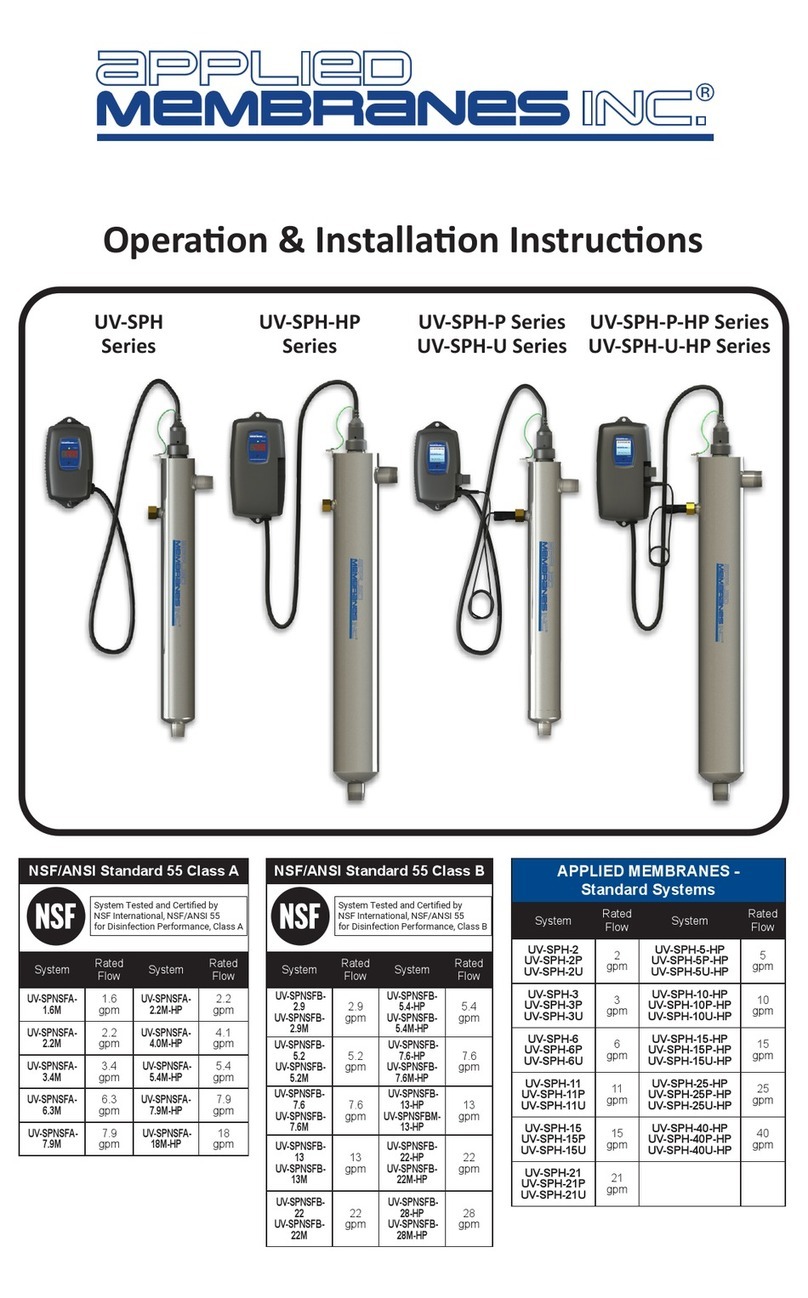

Applied Membranes UV-SPH Series User manual

Applied Membranes

Applied Membranes AAA-124 Manual

Applied Membranes

Applied Membranes AMI DELUXE Owner's manual

Applied Membranes

Applied Membranes AAA-125 Owner's manual

Applied Membranes

Applied Membranes L Series Manual

Applied Membranes

Applied Membranes W-G2162EM Instruction Manual

Popular Water Filtration System manuals by other brands

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual