LinMot C1250-IP Series Installation and operating instructions

March 2020

0185-1120-E_1V5_AN_PLC_Commissioning

PLC Commissioning of LinMot Servo Drives

Application Note / How-to

© 2020 NTI AG

This work is protected by copyright.

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, microfilm, storing in an information retrieval system, not even for

didactical use, or translating, in whole or in part, without the prior written consent of NTI AG.

LinMot® is a registered trademark of NTI AG.

Note

The information in this documentation reflects the stage of development at the time of press and is therefore

without obligation. NTI AG reserves itself the right to make changes at any time and without notice to reflect

further technical advance or product improvement.

NTI AG

LinMot®

Bodenaeckerstrasse 2

CH-8957 Spreitenbach

Tel: +41 56 419 91 91

Fax: +41 56 419 91 92

Email: office@linmot.com

Homepage: www.linmot.com

PLC Commissioning

NTI AG / LinMot

Page 3 of 205

Table of Contents

Table of Contents ..................................................................................................................................................3

Use of This Document ..........................................................................................................................................8

Version History ......................................................................................................................................................8

Trademarks ............................................................................................................................................................9

1 General ..............................................................................................................................................................10

1.1 Abbreviations.................................................................................................................................................10

1.1.1 LinMot Drive System Generations (SG)...................................................................................................10

1.1.2 LinMot Drive Interface Extensions ...........................................................................................................10

1.2 Available LinMot Libraries .............................................................................................................................10

1.3 Documentation / User Manuals.....................................................................................................................11

1.4 UPID (Unique Parameter ID) ........................................................................................................................12

1.5 Recent Version of LinMot-Talk and Drive Firmware......................................................................................12

2 Overview ...........................................................................................................................................................13

2.1 LinMot Profile (Commissioning using the LinMot Libraries)..........................................................................13

2.2 Drive Profiles (Direct Integration as Motion Axis using standardized Drive Profiles)....................................14

3 LinMot Profile: Beckhoff TwinCAT 2&3..........................................................................................................15

3.1 Overview .......................................................................................................................................................15

3.2 Configuration and Connection of the LinMot Drive .......................................................................................16

3.2.1 Motor Configuration..................................................................................................................................16

3.2.2 XML Files .................................................................................................................................................16

3.2.3 EtherCAT Connection ..............................................................................................................................16

3.3 PLC Setup EtherCAT (E1450-EC-QN, E1250-EC-UC, C1x00-EC-XC-xx)...................................................17

3.3.1 Insert LinMot Drive as Slave ....................................................................................................................17

3.3.2 Config Module ..........................................................................................................................................18

3.3.3 Links to PLC Control ................................................................................................................................19

3.3.4 Check EoE settings..................................................................................................................................20

3.4 Check with LinMot-Talk if the Fieldbus is running .........................................................................................21

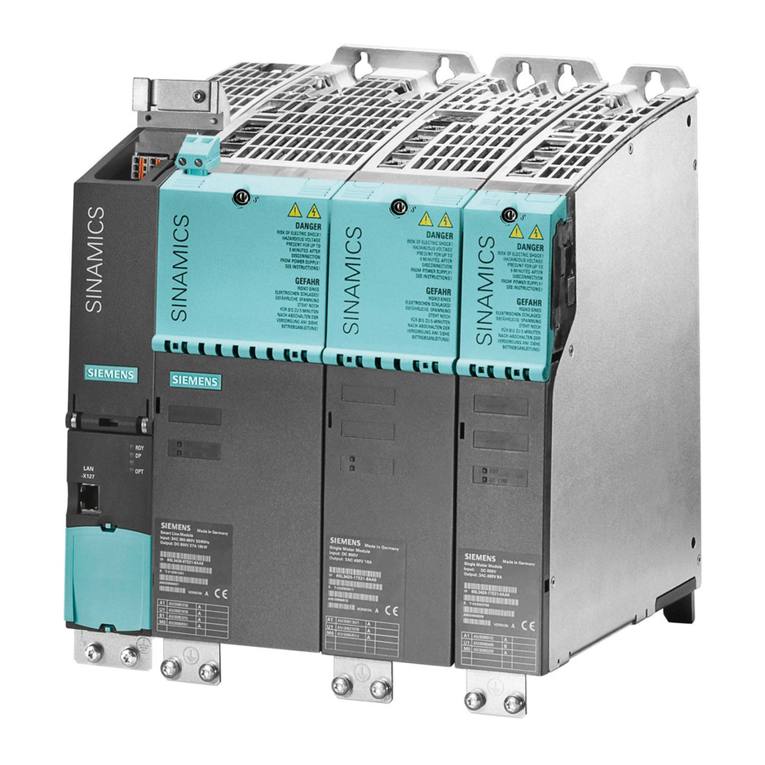

4 LinMot Profile: Siemens TIA ...........................................................................................................................22

4.1 Overview .......................................................................................................................................................22

4.2 Configuration and Connection of the LinMot Drive .......................................................................................23

4.2.1 Motor configuration ..................................................................................................................................23

4.2.2 GSD / GSDML files ..................................................................................................................................23

4.2.3 PROFIBUS Connection ...........................................................................................................................23

4.2.4 PROFINET Connection............................................................................................................................25

4.3 PLC Setup PROFIBUS (E1430-DP-QN, E1230-DP-UC, E1130-DP-xx) ......................................................26

4.4 PLC Setup PROFINET (E1450-PN-QN, E1250-PN-UC, C1250-PN-UC, C1150PN-UC) ............................28

4.4.1 Assigning the Device Name and IP Address............................................................................................30

4.5 Check with LinMot-Talk if the Fieldbus is running .........................................................................................33

5 LinMot Profile: Rockwell RSLogix 5000 / Logix Designer............................................................................34

5.1 Overview .......................................................................................................................................................34

5.2 Minimum Requirements ................................................................................................................................34

5.3 Configuration and Connection of the LinMot Drive .......................................................................................35

5.3.1 Motor Configuration..................................................................................................................................35

5.3.2 EDS Files (Requires RSLogix 5000 V20 or higher) .................................................................................35

5.3.3 EtherNet/IP Connection ...........................................................................................................................35

5.3.4 IP Address ................................................................................................................................................35

5.4 PLC Setup EtherNet/IP .................................................................................................................................36

5.4.1 RSLinx Classic .........................................................................................................................................36

5.4.2 Add a LinMot drive using AOP (E1250-IP-xx, C1250-IP-xx)....................................................................37

PLC Commissioning

Page 4 of 205

NTI AG / LinMot

5.4.3 Add a LinMot drive using the EDS file (recommended for Studio <V31) .................................................41

5.4.4 Add a LinMot drive as Generic Ethernet Module (ETHERNET-MODULE)..............................................44

5.5 Check with LinMot-Talk if the Fieldbus is running .........................................................................................46

6 Drive Profile: Siemens TIA, PROFIdrive.........................................................................................................47

6.1 Overview .......................................................................................................................................................47

6.2 Configuration and Connection of the LinMot Drive .......................................................................................48

6.2.1 Motor Configuration..................................................................................................................................48

6.2.2 GSDML File..............................................................................................................................................49

6.2.3 PROFINET Connection............................................................................................................................49

6.3 PLC Setup .....................................................................................................................................................50

6.3.1 Install GSDML File(s) ...............................................................................................................................50

6.3.2 Insert the LinMot Drive as Device ............................................................................................................50

6.3.3 Set PROFINET Name and IP Address ....................................................................................................51

6.3.4 Insert and Setup a new Technology object (Linear Axis) .........................................................................53

6.3.5 Insert and Setup a new Technology object (Rotary Axis) ........................................................................59

6.4 Home / Set Reference...................................................................................................................................65

6.4.1 Home the Linear Axis ...............................................................................................................................65

6.4.2 Home / Set Reference of the Rotary Axis ................................................................................................67

6.4.3 Active Homing for both linear and rotary motors......................................................................................68

6.5 Parameter Access (RAM)..............................................................................................................................70

6.6 Add Additional Parameters / Variables to the Real-Time Channel ...............................................................71

6.6.1 Drive Configuration ..................................................................................................................................71

6.6.2 PLC Configuration....................................................................................................................................72

6.7 Tuning the Control Loops ..............................................................................................................................73

6.7.1 Drive Control Loop ...................................................................................................................................73

6.7.2 PLC Control Loop.....................................................................................................................................75

6.8 Check with LinMot-Talk if the Fieldbus is running .........................................................................................76

7 Drive Profile: Rockwell Motion using PVA Streaming (CIP Sync) ...............................................................77

7.1 Overview .......................................................................................................................................................77

8 Drive Profile: Beckhoff TwinCAT 2/3, SoE .....................................................................................................78

8.1 Overview .......................................................................................................................................................78

8.2 Configuration and Connection of the LinMot Drive .......................................................................................79

8.2.1 Motor Configuration..................................................................................................................................79

8.2.2 XML File ...................................................................................................................................................80

8.2.3 EtherCAT Connection ..............................................................................................................................80

8.3 PLC Setup .....................................................................................................................................................81

8.3.1 EtherCAT Device Description File XML ...................................................................................................81

8.3.2 Scanning the EtherCAT for new Devices .................................................................................................81

8.3.3 Setting up the Process Data of the LinMot Drive .....................................................................................83

8.3.4 Check EoE settings..................................................................................................................................85

8.3.5 Setting up the NC Axis .............................................................................................................................86

8.4 Encoder Parameter Examples for Linear and Rotary Motors .......................................................................88

8.4.1 Linear Motors PS01 / PS10 .....................................................................................................................88

8.4.2 Rotary Motors RS01 & RS02 ...................................................................................................................88

8.4.3 Rotary Motors EC02.................................................................................................................................89

8.4.4 Other motors ............................................................................................................................................89

8.5 Homing ..........................................................................................................................................................90

8.6 Visualization ..................................................................................................................................................91

8.7 Drive Reset....................................................................................................................................................91

8.8 Asynchronous Parameter Access .................................................................................................................92

8.9 Add Additional Parameters or Variables to the Process Data (MDT 1 / AT 1) ..............................................94

PLC Commissioning

NTI AG / LinMot

Page 5 of 205

9 Drive Profile: Beckhoff TwinCAT 2/3, CoE DS402.........................................................................................97

9.1 Overview .......................................................................................................................................................97

9.2 Configuration and Connection of the LinMot Drive .......................................................................................98

9.2.1 Motor Configuration..................................................................................................................................98

9.2.2 XML File ...................................................................................................................................................99

9.2.3 EtherCAT Connection ..............................................................................................................................99

9.3 PLC Setup ...................................................................................................................................................100

9.3.1 EtherCAT Device Description File XML .................................................................................................100

9.3.2 Scanning the EtherCAT for new Devices ...............................................................................................100

9.3.3 Setting up the Process Data of the LinMot Drive ...................................................................................102

9.3.4 Check EoE settings................................................................................................................................104

9.3.5 Setting up the NC Axis ...........................................................................................................................105

9.4 Encoder Parameter Examples for Linear and Rotary Motors (Axis > Enc) ................................................107

9.4.1 Linear Motors PS01 / PS10 ...................................................................................................................107

9.4.2 Rotary Motors RS01 & RS02 .................................................................................................................107

9.4.3 Rotary Motors EC02...............................................................................................................................108

9.4.4 Other motors ..........................................................................................................................................108

9.5 Homing ........................................................................................................................................................109

9.6 Visualization ................................................................................................................................................110

9.7 Drive Reset.................................................................................................................................................. 110

9.8 Asynchronous Parameter Access ................................................................................................................111

9.9 Add Positive and Negative torque/force limit (0x1711) to the Process Data .............................................. 113

9.10 Add Additional Parameters or Variables to the Process Data................................................................... 115

10 Drive Profile: Schneider Electric PacDrive 3, FSP_DRIVE.......................................................................119

10.1 Overview ...................................................................................................................................................119

10.2 Configuration and Connection of the LinMot Drive ...................................................................................120

10.2.1 Motor Configuration..............................................................................................................................120

10.2.2 Sercos Connection...............................................................................................................................121

10.2.3 Sercos Address ....................................................................................................................................122

10.3 PLC Setup .................................................................................................................................................123

10.3.1 General Device Properties ...................................................................................................................123

10.3.2 Add the LinMot Drive to the Sercos .....................................................................................................124

10.3.3 Device Configuration............................................................................................................................125

10.3.3.1 Identification ....................................................................................................................................125

10.3.3.2 Motor/Mechanic using a LinMot linear motor..................................................................................126

10.3.3.3 Motor/Mechanic using a rotary motor .............................................................................................127

10.3.3.4 Realtime channel ............................................................................................................................128

10.4 Homing (Linear Motors) ............................................................................................................................129

10.4.1 Homing using the Schneider template (FB_Home) .............................................................................129

10.4.1.1 Setup...............................................................................................................................................129

10.4.2 Drive-Based Homing (S-0-0148)..........................................................................................................130

10.5 Parameter Access .....................................................................................................................................131

10.5.1 Supported UPID Functions via IDN Access over the Sercos Service Channel ...................................131

10.5.2 Read RAM Parameter Example...........................................................................................................132

10.5.3 Write RAM Parameter Example ...........................................................................................................133

10.6 Enable/Disable Drive Warnings ................................................................................................................134

11 Drive Profile: CODESYS SoftMotion, CiA402 ............................................................................................135

11.1 Overview....................................................................................................................................................135

11.2 Configuration and Connection of the LinMot Drive ...................................................................................136

11.2.1 Motor Configuration..............................................................................................................................136

11.2.2 XML File ...............................................................................................................................................137

PLC Commissioning

Page 6 of 205

NTI AG / LinMot

11.2.3 EtherCAT Connection...........................................................................................................................137

11.3 PLC Setup .................................................................................................................................................138

11.3.1 EtherCAT Device Description File XML................................................................................................138

11.3.2 Add and setup the LinMot drive............................................................................................................138

11.3.3 Check EoE settings ..............................................................................................................................140

11.4 Homing ......................................................................................................................................................141

11.5 Visualization ..............................................................................................................................................142

11.6 Parameter Access .....................................................................................................................................143

11.7 Add Additional Parameters or Variables to the Process Data ...................................................................144

12 Drive Profile: B&R NC Motion using the SDC interface ...........................................................................147

12.1 Overview ...................................................................................................................................................147

12.2 Compatibility LinMot_SDC <> ACP10 ARNC0 .........................................................................................148

12.3 Configuration and Connection of the LinMot Drive ...................................................................................149

12.3.1 Motor Configuration..............................................................................................................................149

12.3.2 XDD File ...............................................................................................................................................150

12.3.3 Powerlink Connection ..........................................................................................................................150

12.3.4 Node ID ................................................................................................................................................150

12.4 Short Description of the LinMot SDC interface function block ..................................................................151

12.4.1 Principle of Operation...........................................................................................................................151

12.4.2 HTML Help ...........................................................................................................................................151

12.4.3 LM_SdcIf (Interface Function Block)....................................................................................................152

12.4.4 enCallType ...........................................................................................................................................152

12.4.5 stConfig ................................................................................................................................................152

12.5 Prerequisites .............................................................................................................................................153

12.6 Automation Studio Physical View..............................................................................................................154

12.6.1 Add the LinMot drive to the Powerlink network ....................................................................................154

12.6.2 Configuration........................................................................................................................................155

12.6.3 I/O Mapping..........................................................................................................................................156

12.6.4 Powerlink Interface and PLC Configuration .........................................................................................157

12.6.5 Add a B&R drive to generate all NC object specific requirements automatically ................................158

12.7 Automation Studio Configuration View......................................................................................................160

12.7.1 Setup NC Manager and NC Mapping ..................................................................................................160

12.7.2 Add new NC Object..............................................................................................................................162

12.7.3 Add TextSystem ...................................................................................................................................163

12.8 Automation Studio Logical View: Linear Motor Example ..........................................................................165

12.8.1 Add the example program to the project ..............................................................................................165

12.8.2 ACOPOS Parameter Table...................................................................................................................165

12.8.3 Init Parameter Table .............................................................................................................................166

12.8.4 Check Init Parameters of the SDC function block................................................................................167

12.8.5 Assign the example program to Cyclic #1............................................................................................167

12.9 Automation Studio Logical View: Rotary Motor Example..........................................................................168

12.9.1 Add the example program to the project ..............................................................................................168

12.9.2 ACOPOS Parameter Table...................................................................................................................169

12.9.3 Init Parameter Table .............................................................................................................................171

12.9.4 Check Init Parameters of the SDC function block................................................................................172

12.9.5 Assign the example program to Cyclic #1............................................................................................172

12.10 Homing ....................................................................................................................................................173

12.10.1 Linear Motor .......................................................................................................................................173

12.10.2 Rotary Motor ......................................................................................................................................173

12.10.3 Reference Switch (mcHOME_ABS_SWITCH) ..................................................................................174

12.11 Test ..........................................................................................................................................................176

PLC Commissioning

NTI AG / LinMot

Page 7 of 205

12.11.1 Switch On ...........................................................................................................................................176

12.11.2 Homing ...............................................................................................................................................177

12.11.3 Error Acknowledge .............................................................................................................................177

12.12 Parameter Access ...................................................................................................................................178

12.12.1 Parameter access by LMcf_ParaAccess function block ....................................................................178

12.12.2 Parameter access by SDO commands..............................................................................................179

12.13 Add Additional Parameters or Variables to the Process Data.................................................................181

12.14 Errors (LM_SdcIf outputs) .......................................................................................................................182

12.14.1 bError .................................................................................................................................................182

12.14.2 diStatusID...........................................................................................................................................182

12.14.3 uiErrorCode ........................................................................................................................................182

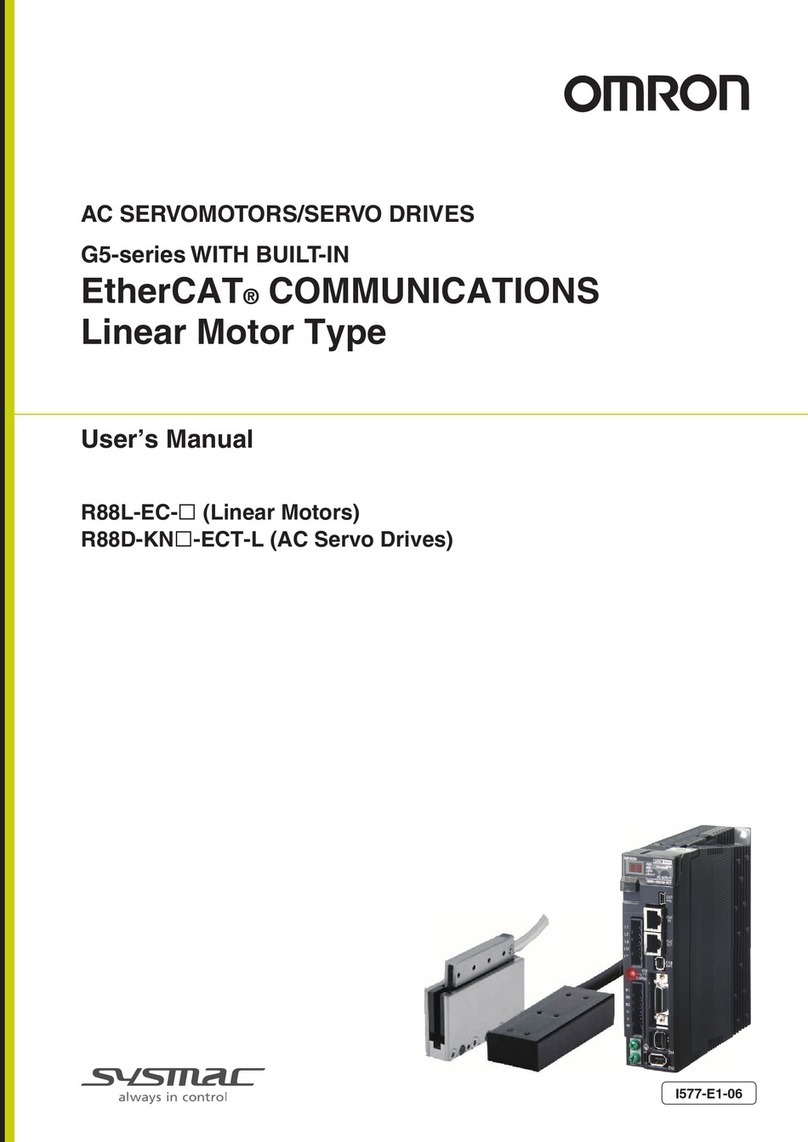

13 Drive Profile: OMRON Sysmac Studio, CoE DS402..................................................................................183

13.1 Overview ...................................................................................................................................................183

13.2 Configuration and Connection of the LinMot Drive ...................................................................................184

13.2.1 Motor Configuration..............................................................................................................................184

13.2.2 XML File ...............................................................................................................................................185

13.2.3 EtherCAT Connection ..........................................................................................................................185

13.3 PLC Setup .................................................................................................................................................186

13.3.1 EtherCAT Device Description File XML ...............................................................................................186

13.3.2 Define EtherCAT node address on LinMot-Device ..............................................................................186

13.3.2.1 Set node address by address selector on device ...........................................................................187

13.3.2.2 Set node address by parameter on device .....................................................................................188

13.3.2.3 Set node address by EtherCAT Master ..........................................................................................189

13.3.3 Scanning the EtherCAT for new Devices .............................................................................................190

13.3.4 Create a motion axis and link it to your physical LinMot axis ..............................................................191

13.3.5 Setting up the motion axis....................................................................................................................193

13.4 Drive based homing ..................................................................................................................................194

13.4.1 Settings on LinMot drive ......................................................................................................................194

13.4.2 Function blocks required on Sysmac ...................................................................................................195

13.4.2.1 EC_CoESDOWrite ..........................................................................................................................195

13.4.2.2 MC_ResetFollowingError................................................................................................................195

13.4.2.3 MC_HomeWithParameter...............................................................................................................195

13.4.3 Homing procedure on Sysmac.............................................................................................................196

13.5 Drive Reset................................................................................................................................................197

13.6 Parameter Access .....................................................................................................................................198

13.7 Add Additional Parameters or Variables to the Process Data (PDO Map) ...............................................199

14 Troubleshooting ...........................................................................................................................................200

Appendix I: Basic Position Control Loop Tuning ..........................................................................................202

Notes ..................................................................................................................................................................204

Contact & Support.............................................................................................................................................205

PLC Commissioning

Page 8 of 205

NTI AG / LinMot

Use of This Document

This document is an Application Note / How-To to help the user connecting LinMot drives to different PLC types.

It provides guides when using function block libraries provided by NTI AG / LinMot and guides to integrate

LinMot drives using standardized drive profiles.

This document is provided by NTI AG / LinMot free of charge with no warranty for updates.

Also, LinMot accepts no liability for damages that may be caused by using this document or programming

examples referred to.

Drives: Various

Classification: [x] Application Note

[x] Installation Guide

[x] User Manual

[x] Documentation

[x] LinMot internally

Version History

Version

Date

Author

Description

1V0

31/05/2017

fj

Initial Release

1V1

13/06/2017

fj

Minor corrections

1V2

10/07/2017

fj

Added chapter 11 Drive Profile: CODESYS SoftMotion, CiA402

1V3

27/03/2019

fj / mm

Added chapter 7 Drive Profile: Rockwell Motion using PVA Streaming (CIP Sync)

Added chapter 8.4 Encoder Parameter Examples for Linear and Rotary Motors

Added chapter 9 Drive Profile: Beckhoff TwinCAT 2/3, CoE DS402

Added chapter 10.3.3.3 Motor/Mechanic using a rotary motor

Added chapter 12 Drive Profile: B&R NC Motion using the SDC interface

Updated chapter 6 Drive Profile: Siemens TIA, PROFIdrive

Removed chapter OMRON with EC drives (obsolete)

Various minor updates and corrections

1V4

03/06/2019

fj

Minor: added library compatibility list: chapter 12.2

Minor: fixed screenshot and description in chapter 12.13

1V5

26/02/2020

fj

Added chapter 10.4.1 Homing using the Schneider template (FB_Home)

Added chapter Trademarks

Various minor updates and corrections

PLC Commissioning

NTI AG / LinMot

Page 9 of 205

Trademarks

Product and company names and logos referenced may be either trademarks or registered trademarks of their

respective companies. The sole purpose of any trademarks in this document is the identification of the

corresponding products.

Company

Trademarks / Registered Trademarks

Siemens AG

SIEMENS®, SIMATIC®, TIA Portal®, Step 7®

Rockwell Automation, Inc

Rockwell Automation®, Allen-Bradley®, CompactLogix™, ControlLogix®, Studio 5000®, Studio

5000 Logix Designer®, RSLogix 5000®, Stratix®, RSLinx®,

Beckhoff Automation GmbH

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®

Schneider Electric

PacDrive®, SoMachine®

Bosch Rexroth

IndraControl, IndraMotion

3S-Smart Software Solutions GmbH

CODESYS

B&R Industrial Automation GmbH

B&R Automation Studio®, Ethernet POWERLINK®

Omron

SYSMAC®,

Profibus and Profinet International (P.I.)

Profibus®, Profinet®

Interests Group SERCOS interface e.V

SERCOS interface®

ODVA, Inc

EtherNet/IP™, CIP™, CIP Sync™,

All other product and company names and marks mentioned in this document are the property of their

respective owners and are mentioned for identification purposes only.

PLC Commissioning

Page 10 of 205

NTI AG / LinMot

1 General

1.1 Abbreviations

1.1.1 LinMot Drive System Generations (SG)

SG

Drives

SG3

Family E1100 (GP, CO, DN, DP) (LC/HC/XC)

SG4

Family B1100 (VF, PP, GP, ML) (LC/HC/XC)

SG5

Family E1200 (GP, DP, DS, EC, IP, PD, PL, PN, SC, SE, LU)

Family E1400 (GP, DP, DS, EC, IP, PD, PL, PN, SC, SE, LU) (0S/1S)

Family B8000-ML (GP, EC, IP, PL, PN, SC)

SG6

Family C1250 (DS, EC, CM, IP, PD, PL, PN, SC, SE, LU) (0S/1S)

Family E1400V2 (GP, DP, DS, EC, IP, PD, PL, PN, SC, SE, LU) (0S/1S)

Family C1400 (GP, DS, EC, IP, PD, PL, PN, SC, SE, LU) (0S/1S)

SG7

Family A1100

Family C1100 (GP, DS, EC, PD, PN, SE) (0S/1S)

1.1.2 LinMot Drive Interface Extensions

Extension

Interface

GP

General Purpose (Depends on system generation and installed FW: LinRS and/or CANopen and/or DeviceNet)

CO

CANopen (LinMot Profile)

DN

DeviceNet (LinMot Profile)

DP

PROFIBUS (LinMot Profile)

PN

PROFINET (LinMot Profile)

PD

PROFIdrive (PROFIdrive Standard Telegram 5 & 9, SIEMENS Telegram 105)

EC

EtherCAT (LinMot Profile)

SE

EtherCAT SoE (Servo Drive Profile over EtherCAT)

DS

EtherCAT CoE (DS402, CiA402)

PL

Powerlink (LinMot Profile)

IP

EtherNet/IP (LinMot Profile)

CM

EtherNet/IP (CIP Sync, LinMot Profile)

SC

Sercos III (FSP_DRIVE, FSP_IO)

LU

LinUDP (LinMot Ethernet UDP protocol)

RS

LinRS (LinMot serial protocol for RS232, RS422, RS485)

E.g. C1250-SE-XC-xS -> SE = EtherCAT SoE

1.2 Available LinMot Libraries

LinMot provides several function block libraries for different PLCs and fieldbus systems to allow a fast and

comfortable integration of LinMot drives into almost any control concept.

An overview of available LinMot libraries can be downloaded from the LinMot website:

http://www.linmot.com/support/plc-library/

Or search for the document reference (0185-1105) in the LinMot eCatalogue:

http://shop.linmot.com

Note: The available libraries can be downloaded from: http://download.linmot.com/plc_lib/libraries

For preliminary libraries that are not available for download please contact the LinMot support team.

PLC Commissioning

NTI AG / LinMot

Page 11 of 205

1.3 Documentation / User Manuals

Beside the documentation included in the libraries available for download, reading the following user manuals is

essential to understand the communication between the PLC and the LinMot drive. The manuals are included in

the LinMot-Talk software (Menu Manuals → All Documents or Relevant Documents if logged in to a drive) or can

be downloaded from the LinMot eCatalogue (search by document reference): http://shop.linmot.com

User Manuals: General

System Generation

Document Reference

LinMot-Talk

All

0185-1059

Motion Control Software

SG3 & SG4

0185-1092

Motion Control Software

SG5 - SG7

0185-1093

User Manuals: Configuration Over Fieldbus

System Generation

Document Reference

Drive Configuration Over Fieldbus

SG3

0185-1072

Drive Configuration Over Fieldbus

SG4

0185-1073

Drive Configuration Over Fieldbus

SG5 - SG7

0185-1074

User Manuals: Interfaces

System Generation

Document Reference

EtherCAT (LinMot Profile)

SG5 - SG7

0185-1079

EtherCAT SoE (Servo Drive Profile over EtherCAT)

SG5 - SG7

0185-1080

EtherCAT CoE (CiA402, CANopen over EtherCAT)

SG5 - SG7

0185-1103

PROFIBUS DP

SG3, SG5 & SG6

0185-1089

PROFINET IO

SG5 - SG7

0185-1090

PROFINET PROFIdrive

SG6

0185-1132

Sercos III (FSP_DRIVE or FSP_IO)

SG5 & SG6

0185-1091

EtherNet/IP

SG5 & SG6

0185-1081

EtherNet/IP CIP Sync

SG6

0185-1165

Powerlink

SG5 & SG6

0185-1088

CANopen

SG3 & SG4

0185-1075

CANopen

SG5 - SG7

0185-1076

DeviceNet

SG3 & SG4

0185-1078

LinRS (LinMot serial protocol)

SG3 - SG7

0185-1082

LinUDP (Linmot Ethernet UDP protocol) up to FW6.3

SG5 & SG6

0185-1083

LinUDP V2 (LinMot Ethernet UDP protocol) from FW6.3

SG5 & SG6

0185-1108

PLC Commissioning

Page 12 of 205

NTI AG / LinMot

1.4 UPID (Unique Parameter ID)

The value of any parameter of a LinMot drive is stored as an integer value (raw data) in the memory space of

the drive. The parameter is identified through its Unique Parameter ID (UPID), which is a 16 Bit integer number.

Note: Detailed information about LinMot drive parameters can be found in the user manual Drive

Configuration Over Fieldbus. See chapter 1.3 Documentation / User Manuals

Attention ROM Access:

Intense use of writing into the ROM memory can reduce the lifetime of the drive memory!

More details can be found in the Drive Configuration Over Fieldbus (0185-1074) user manual

> see chapter Documentation / User Manuals

1.5 Recent Version of LinMot-Talk and Drive Firmware

The most recent LinMot-Talk version including all drive firmware, device description files and documentation can

be downloaded from

either:

https://linmot.com/download/linmot-talk-drive-configuration/

or:

http://download.linmot.com/LinMot-Talk/Release/

Hint:

LinMot C1250, C1450 & E1450 series drives support configuration over several interfaces (ProfiNet,

EtherNet/IP, EtherCAT, Sercos III & LinUDP). This allows to login with LinMot-Talk into the drive and

change parameters, monitor the drive, import/export the drive configuration, etc.

Please request the according application note from support@linmot.com

PLC Commissioning

NTI AG / LinMot

Page 13 of 205

2 Overview

2.1 LinMot Profile (Commissioning using the LinMot Libraries)

The following table shows working combinations of different PLC types and LinMot drives. For these

combinations function block libraries and/or example projects are available. Click the link in the See chapter

column to directly open the according chapter (if available).

PLC Type

Interface

LinMot I/F Extension

Type

Language

See chapter

Beckhoff TwinCAT 2&3

EtherCAT

CANopen

PROFIBUS

-EC

-GP

-DP

Library

ST (Structured Text)

3

Siemens Step 7 V5.5

(S7-300 and higher)

PROFINET

PROFIBUS

-PN

-DP

Library

AWL

4

Siemens TIA

(S7-300, S7-1500)

PROFINET

PROFIBUS

-PN

-DP

Library

AWL

4

Siemens TIA

(S7-1200, S7-1500)

PROFINET

PROFIBUS

-PN

-DP

Library

SCL

4

Rockwell Automation

EtherNet/IP

-IP

Addon Instructions (AOI)

LD (Ladder)

5

B&R

Powerlink

CANopen

-PL

-GP

Library

ST

Not yet

CODESYS 2.x / 3.x

Various

Various

Library

ST

Not yet

PLC Commissioning

Page 14 of 205

NTI AG / LinMot

2.2 Drive Profiles (Direct Integration as Motion Axis using standardized Drive Profiles)

The following table shows the drive profiles supported by LinMot servo drives. Based on your PLC type the

correct LinMot drive can be selected. Click the link in the See chapter column to directly open the according

chapter (if available).

PLC Type

Interface

LinMot I/F Extension

Integration

Drive Profile

See chapter

Siemens

(Simotion, S7-1500, …)

PROFIdrive

-PD

As axis

Standard Telegram 5

SIEMENS Telegram 105

6

Rockwell Automation

EtherNet/IP (CIP Sync)

-CM

As motion axis

LinMot PVA Streaming

7

Beckhoff TwinCAT 2&3

EtherCAT SoE

-SE

As NC axis

SoE

8

Beckhoff TwinCAT 2&3

EtherCAT CoE

-DS

As NC axis

CoE (DS402)

9

Schneider Electric

(PacDrive 3)

Sercos III

-SC

As axis

FSP_DRIVE

10

Bosch Rexroth

(IndraControl /

IndraMotion)

Sercos III

-SC

As axis

FSP_DRIVE

Footnote 1

CODESYS Motion

EtherCAT CoE

-DS

As axis

CoE (DS402)

11

TRIO MC464

(P680)

EtherCAT

-EC

As axis

TRIO specific

Footnote 2

B&R

Powerlink

-PL

As SDC axis

LinMot PV Streaming

12

Omron

(NJ501-1500)

EtherCAT CoE

-DS

As axis

CoE (DS402)

13

1

See Bosch Rexroth online help for GAT compact. The LinMot Sercos (-SC) drives are integrated

as sercosDrive.

2

Contact TRIO Motion for help to integrate. They have directly integrated LinMot EtherCAT drives (-

EC) in their firmware.

PLC Commissioning

NTI AG / LinMot

Page 15 of 205

3 LinMot Profile: Beckhoff TwinCAT 2&3

3.1 Overview

This chapter shows how a LinMot C1250-EC-XC-0S drive (with LinMot EtherCAT interface) can be integrated

and setup in a Beckhoff TwinCAT environment to be used with the library provided by LinMot. For this example,

TwinCAT 2 is used. The steps are generally similar for TwinCAT 3.

The library for TwinCAT 2&3 can be downloaded from:

http://download.linmot.com/plc_lib/libraries/Beckhoff/ (named Beckhoff_LinMot_Library_...)

Note:

More information can be found in the library documentation (part of the above-mentioned download)

and in the user manual EtherCAT (LinMot Profile) (see chapter 1.3 Documentation / User Manuals)

Image Source: http://www.beckhoff.com/

EtherCAT is the open real-time Ethernet network originally developed by Beckhoff. The LinMot acts as Slave in

this network and is implemented with the standard ASIC ET1100 from Beckhoff.

For further information on the EtherCAT fieldbus please visit:

http://www.ethercat.org/

additional device (s)

PLC Commissioning

Page 16 of 205

NTI AG / LinMot

3.2 Configuration and Connection of the LinMot Drive

The LinMot drive is configured using the LinMot-Talk software:

http://www.linmot.com/download/linmot-talk-drive-configuration/

3.2.1 Motor Configuration

It is assumed that the motor connected to the drive is already configured.

Use the Motor Wizard inside LinMot-Talk to setup the motor (Menu -> Drive -> Motor Wizard):

See Appendix I: Basic Position Control Loop Tuning

3.2.2 XML Files

Install the XML file that is part of the LinMot-Talk software/firmware you are using.

The most recent device files are always part of the newest LinMot-Talk software. They are located by default:

•EtherCAT: \\LinMot-Talk X.X Build XXXXXXXX\Firmware\Interfaces\EtherCAT\XML

3.2.3 EtherCAT Connection

The drive is connected to the EtherCAT network using the X17 & X18 connectors.

The below pictures show the ports of an E1250-EC-UC drive. On all other LinMot drives supporting EtherCAT

the ports are named the same (X17 & X18) but they may be placed differently on the drive housing.

PLC Commissioning

NTI AG / LinMot

Page 17 of 205

3.3 PLC Setup EtherCAT (E1450-EC-QN, E1250-EC-UC, C1x00-EC-XC-xx)

3.3.1 Insert LinMot Drive as Slave

The required XML files can be found in the following folder (default):

C:\Program Files\LinMot\LinMot-Talk X.X Build XXXXXXXX\Firmware\Interfaces\EtherCAT\XML

These files have to be copied to the IO folder of TwinCAT:

•C:\TwinCAT\Io\EtherCAT\ (for TwinCAT 2)

•C:\TwinCAT\3.1\Config\Io\EtherCAT\ (for TwinCAT 3)

Note: You may have to restart the developing environment to have the new XML file to be recognized.

Insert a new device by right-click on the EtherCAT-Master and Append Box (figure below) or restart

the PLC to “Config Mode” and scan for the devices attached to the EtherCAT bus.

PLC Commissioning

Page 18 of 205

NTI AG / LinMot

3.3.2 Config Module

The Config Module provides access to parameters, curve profiles, command table and so on of a LinMot drive.

If the config function blocks of the library are used the „Config Module“ inputs and outputs (0x1B08 &

0x1708) have to be enabled and linked as well.

PLC Commissioning

NTI AG / LinMot

Page 19 of 205

3.3.3 Links to PLC Control

To be able to link the input and output data of the LinMot drive you have to create an instance of the tstLM_Axis

data type (part of the library) in the global variables of you PLC project.

The inputs and outputs of the modules must be linked as shown below:

Hint:

It is possible to change multiple links at once. Just select the names you want to link > right-click >

Change Multi Link. Don’t forget to check “All Types” and “Continuous”.

PLC Commissioning

Page 20 of 205

NTI AG / LinMot

3.3.4 Check EoE settings

On supported drives (C1250-..., C1450-… & E1450-...) please check the EoE (Ethernet over EtherCAT)

settings.

LinMot drives do NOT support the DHCP mode yet. A fix IP must be assigned (select IP Address) or the EoE

feature must be completely disabled (disable Virtual Ethernet Port).

Note:

EoE can be used to login into the drive with LinMot-Talk directly over EtherCAT.

E.g. to change drive settings or for monitoring and tracing.

This manual suits for next models

18

Table of contents

Other LinMot Servo Drive manuals

LinMot

LinMot E1250-IP-UC User manual

LinMot

LinMot E1450-PL-QN-0S User manual

LinMot

LinMot C1100 series User manual

LinMot

LinMot C1200 User manual

LinMot

LinMot C1250 Series User manual

LinMot

LinMot C1450 VS-1S Series User manual

LinMot

LinMot C1251-2S User manual

LinMot

LinMot E14 0 V2 Series User manual

LinMot

LinMot C1400-CI-VS-0S-YYY User manual

LinMot

LinMot E1200 Series User manual