B2210092A • 10016604 • 09.22

© 2022 AprilAire | aprilaire.com | 800.334.6011

AprilAire reserves the right to change specications without notice.

90-1522

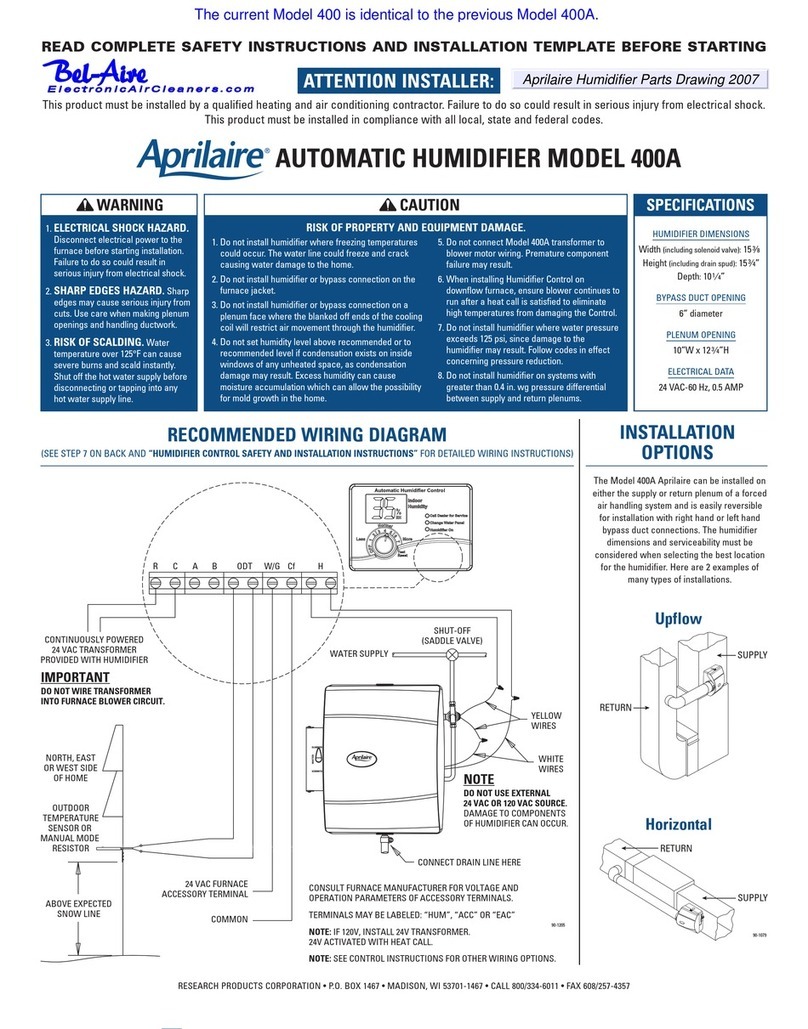

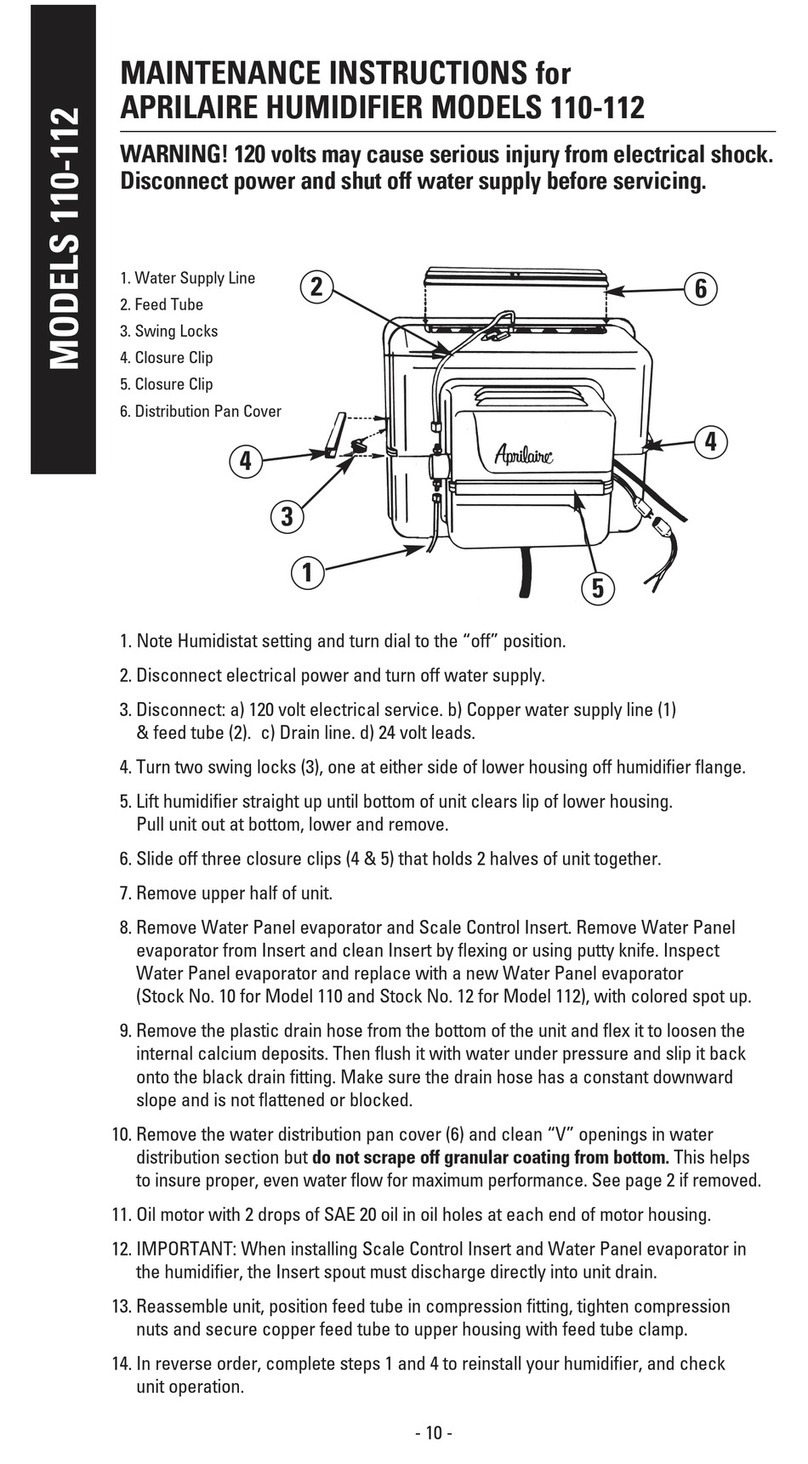

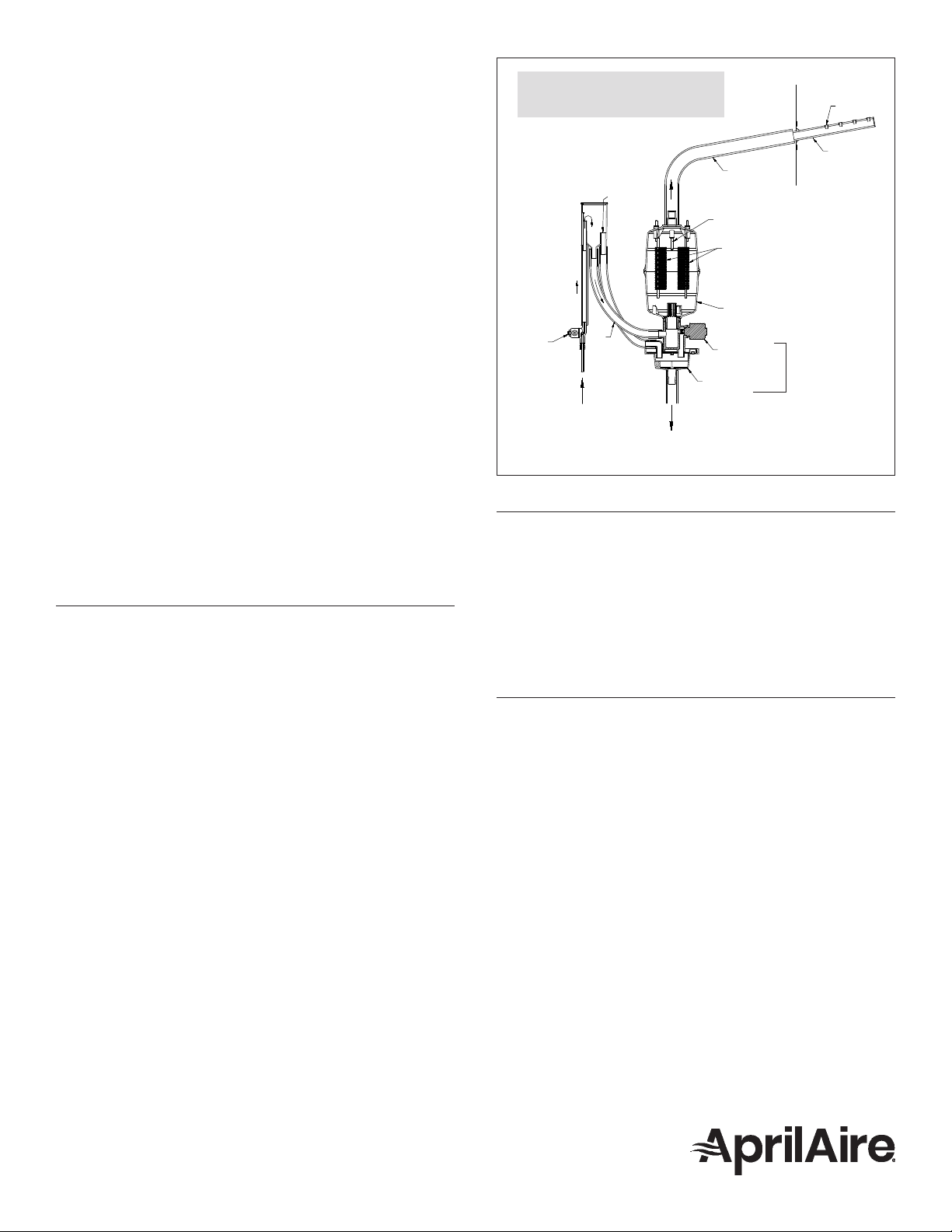

FIGURE 4: FILL & DRAIN

SYSTEM AND CANISTER

Steam

Outlet

Drain

Supply

Water

Drain Cup

Drain Valve

Electrodes

Water Level Probe

Fill Valve

Overflow

Fill

Steam Hose

Dispersion

Tube in

Duct

Tubelets

Canister

Drain

Assembly

5. Slide canister up and out of drain assembly (see FIGURE 4).

Discard old canister.

6. Remove O-ring from drain assembly using small

screwdriver. Discard old O-ring.

7. With your nger, swirl the uid/precipitate mixture in the

bottom of the drain valve reservoir (see FIGURE 4).

8. Using a sponge or paper towels, soak up the water in the

reservoir. If necessary, use a wet/dry vacuum to remove

residue.

9. Clean the inside of the drain port (where coil projects out)

by gently swabbing with a bent cotton swab or other soft

implement.

10. Rinse the drain valve reservoir with clean water and vacuum

as necessary.

11. Insert new O-ring (Part #5258) into slot in drain assembly.

Dampen O-ring with water before inserting canister. Do not

use oil, grease, or any lubricant besides water.

12. Make sure strainer is inserted into bottom of new canister.

13. Insert new canister into drain assembly (see FIGURE 4).

14. Slip steam hose over top of canister and tighten hose lamp

(see FIGURE 4).

15. Reconnect the electrode wires and water level probe wire to

the posts on top of the canister (see Figure 2A and Figure

2B). Electrode wires are interchangeable and can be placed

on either of the two electrode posts on top of the canister.

Ensure connectors are fully seated.

ELECTRODE WIRE REPLACEMENT

1. Remove front panel (see FIGURE 1).

2. Remove side panel (see FIGURE 1).

3. Remove the electrode wires (see FIGURE 2A and FIGURE 2B).

a. For units with one circuit board: Use needle nose pliers

to pull the spade connectors off spade terminals J8 and

J10 on the circuit board.

b. For units with two circuit boards: Use needle nose pliers

to pull the spade connectors off the spade terminals on

the power relay.

4. Ensure the two replacement electrode wires (Part #4978)

have “O” shape connectors (see FIGURE 3B). Do not use

replacement wires with “D” shape connectors (see FIGURE

3A).

5. Attach the new electrode wires (see FIGURE 2A and FIGURE

2B).

a. For units with one circuit board: Use a pair of needle

nose pliers to attach the spade connectors to the spade

terminals J8 and J10 on the circuit board. Electrode wires

are interchangeable and can be placed on either of the

two terminals.

b. For units with two circuit boards: Use a pair of needle

nose pliers to attach the connectors to the spade

terminals on the power relay. One wire, either one but

not both, must go through current-sensing toroid (see

FIGURE 2A). Electrode wires are interchangeable and can

be placed on either of the two terminals.

FILL VALVE SERVICE

1. Disconnect water supply line from ll valve inlet (see

FIGURE 4).

2. Remove in-line strainer from the ll valve inlet port using

a #8 or #10 sheet metal or wood screw with a minimum

length of 0.5”.

3. Clean or replace in-line strainer (Part #4004).

4. Reconnect water supply line to ll valve inlet (see Figure 4).

RESTORE UNIT TO SERVICE

1. Replace side panel if removed (see FIGURE 1).

2. Replace front panel (see FIGURE 1).

3. Inspect drain hose to make sure it is not blocked and has

constant downward slope. Clean or replace if necessary.

4. Inspect and clean condensate pump (if used).

5. Inspect steam hose to make sure it has no low spots and

has constant upward slope from humidier to dispersion

tube in duct. If dispersion tube is mounted below humidier,

inspect drip tee and drain trap.

6. Restore main electrical power to humidier at circuit

breaker.

7. Turn humidier on and verify green On/Off light is

illuminated (see FIGURE 1).

8. Check system operation and inspect all plumbing

connections and piping for signs of cracks or leaks.