1 Version:1.9

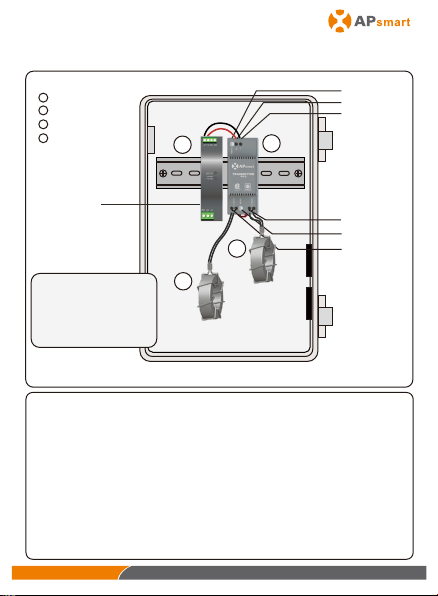

Transmitter-PLC Installation

• Mount Transmitter-PLC and power supply on DIN rail

• Connect DC leads from power supply to transmitter-PLC

• Connect dual core(Core 1 and Core 2) to transmitter-PLC

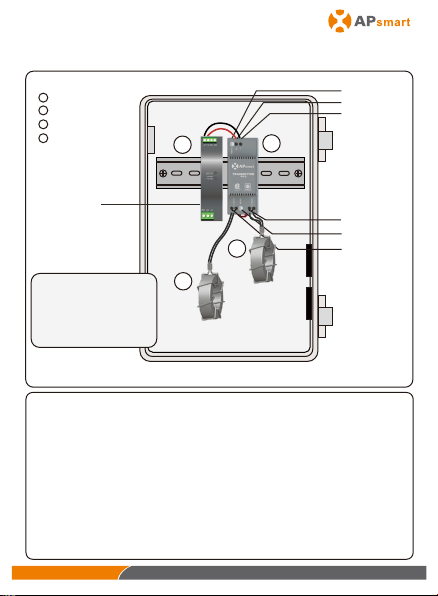

Note: Install RSD before powering on the Transmitter.

Place rapid shutdown system label no more than 1m (3ft) from Transmitter or AC

disconnect if not at same location.

Power supply must be on same AC branch circuit as inverter to meet rapid

shutdown requirements.

During operation,the Power LED should be lit and the Singal LED should be

blinking.When Transmitter fails to work,the singal LED will not be blinking.

If the Power LED is also not lit, check the power supply first.

V -

Power Supply

Transmitter-PLC

Core 1

Core 2

1

2

3

4

Optional Power Supply

120/240VAC

480/277VAC

1

3

4

LED1(Power)

V+

V -

Core 2

LED2(Signal)

Core 1

2

180/550VAC

Power Supply

Transmitter-PLC terminal

installation requirements:

1. A 3mm slotted screwdriver

2. The torque requirement

standard: 0.2-0.4N•m

Note:

Warning:

The cores need to

be fixed to prevent

swing and causing

the damage to the

Transmitter-PLC.

Note: If there is only one core needed, connect using Core 1 terminal.