2

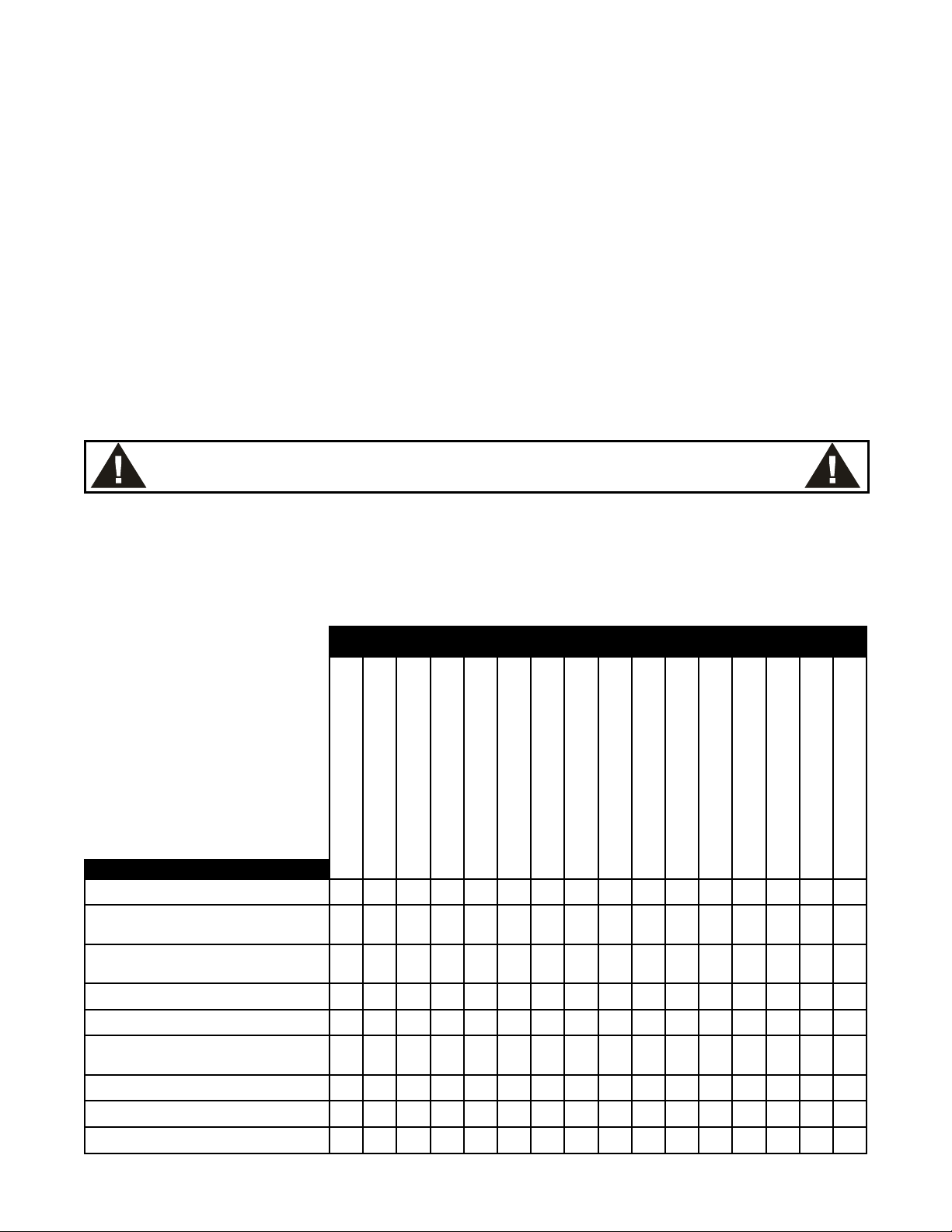

TABLE OF CONTENTS

SECTION ITEM .................. PAGE

1 Safety Precautions/

Safety Information............2

2 General Information ..........4

3 Description .................4

4 Installation & Supply Connections. 4

5 Thermostat Calibration ........5

6 Maintenance ................6

7 Cleaning ...................8

SECTION ITEM .................. PAGE

8 Service ....................8

9 Troubleshooting Guide .......10

10 Suggested Temperature &

Times.....................11

11 Replacement Parts List &

Exploded Views.............11

12 Wiring Diagram .............15

13 Warranty ..................17

APW Wyott takes pride in the design and quality of our products. When used as intended and with

proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read and follow the instructions in this manual carefully.

Installation and start-up should be performed by a qualied installer who thoroughly read, understands

and follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product,

write Technical Service Department: APW Wyott Foodservice Co., Inc., 1307 N Watters Rd. Suite 180,

Allen, TX 75013.

1. SAFETY PRECAUTIONS

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so

that anyone using the equipment will use it correctly and not injure themselves or

harm the equipment.

WARNING: Check the data plate on this unit before installation. Connect the unit

only to the voltage and frequency listed on the data plate. Connect only to 1 or 3

phase as listed on the data plate.

WARNING: Electrical and grounding connections must comply with the applicable

portions of the national electrical code and/or other local electrical codes.

WARNING: Disconnect device from electrical power supply and place a Tag

Out-Lockout on the power plug, indicating that you are working on the circuit.

WARNING: Install per the spacing requirements listed in the installation section of this

manual. We strongly recommend having a competent professional install the equipment.

A licensed electrician should make the electrical connections and connect power to the

unit. Local codes should always be used when connecting these units to electrical power.

In the absence of local codes, use the latest version of the National Electrical Code.

WARNING: This device should be safely and adequately grounded in accordance with

local codes, or in the absence of local codes, with the National Electrical code, ANSI/

NFPA 70, Latest Edition to protect the user from electrical shock. It requires a grounded

system and a dedicated circuit, protected by a fuse or circuit breaker of proper size and

rating. Canadian installation must comply with the Canadian Electrical Code, CSAC22.2,

as applicable.