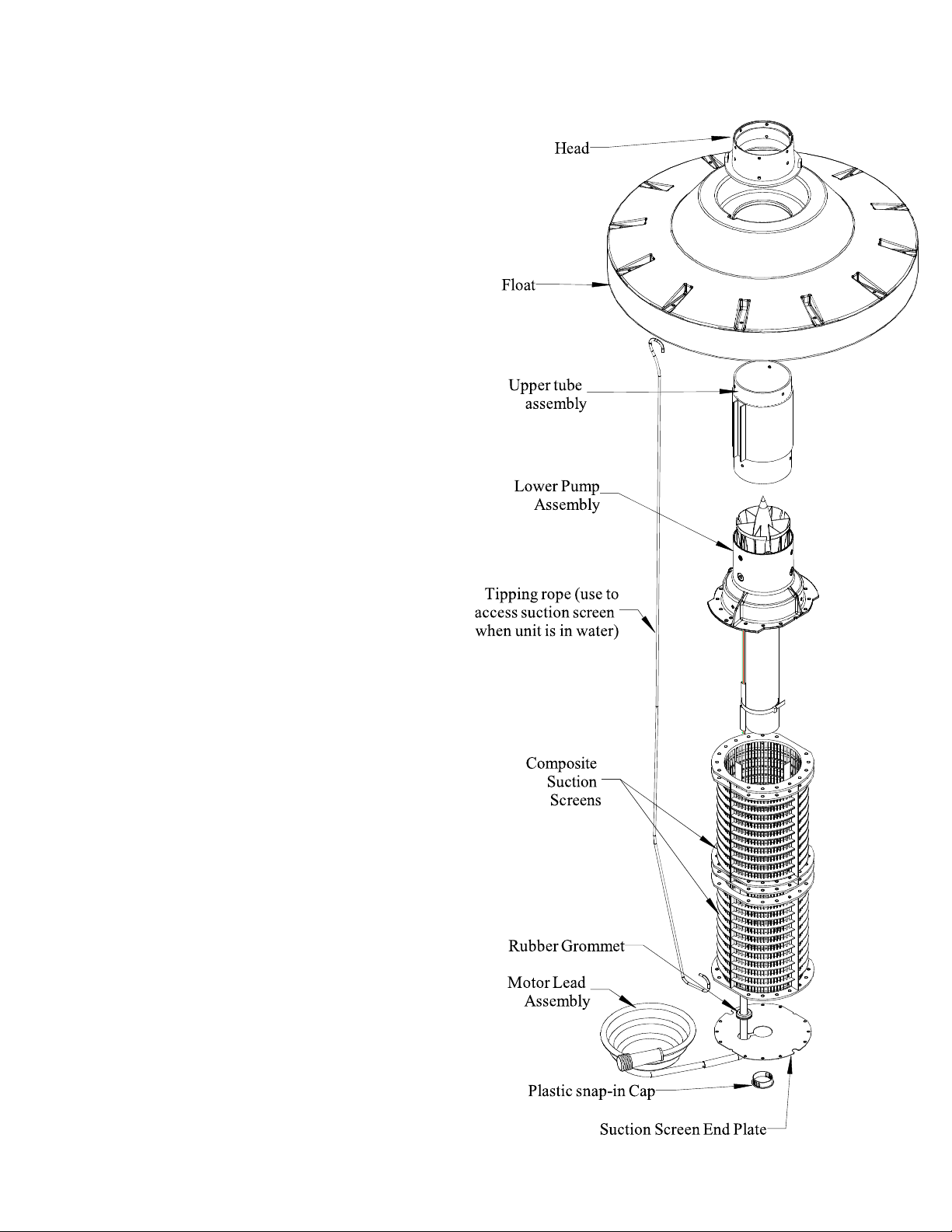

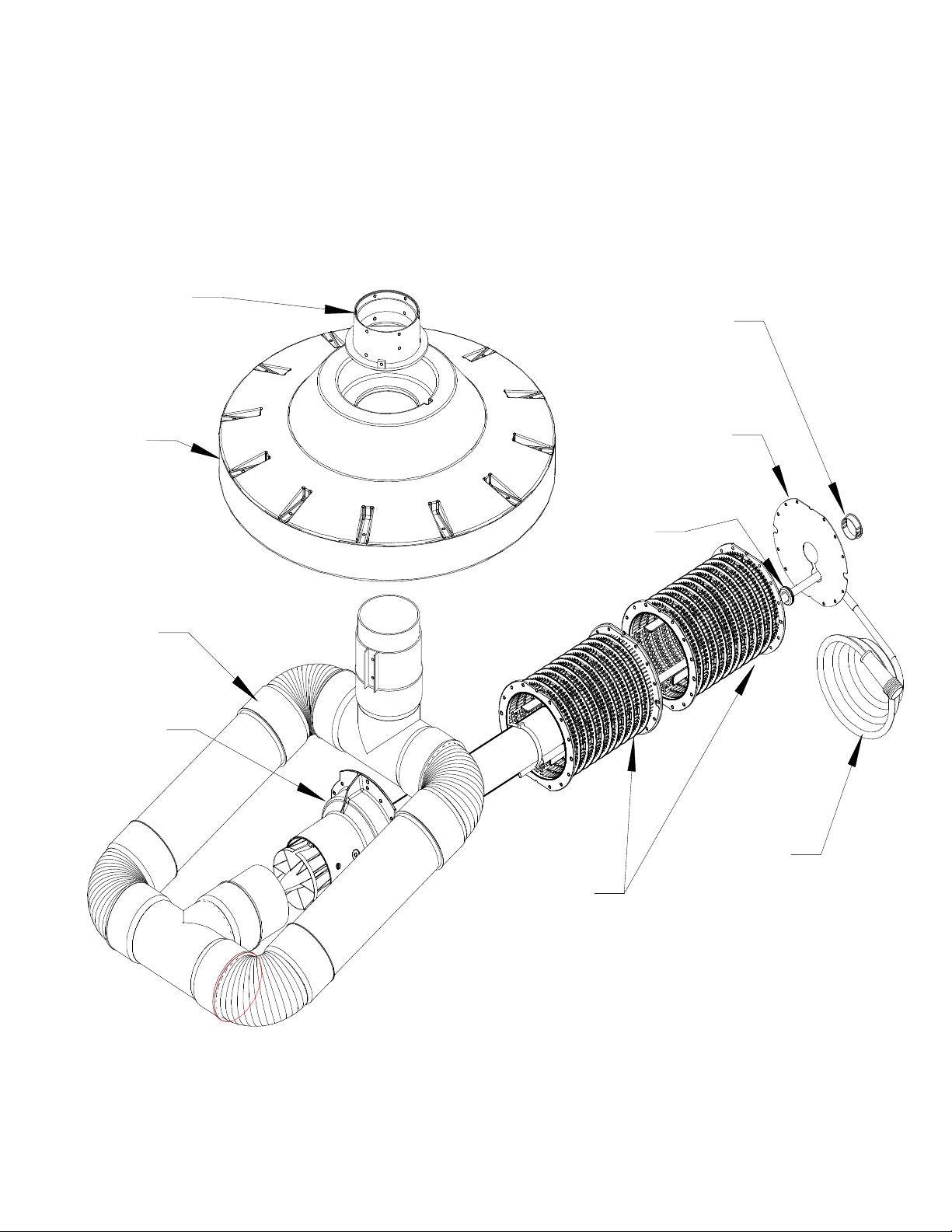

U-BRACKET

FLOAT

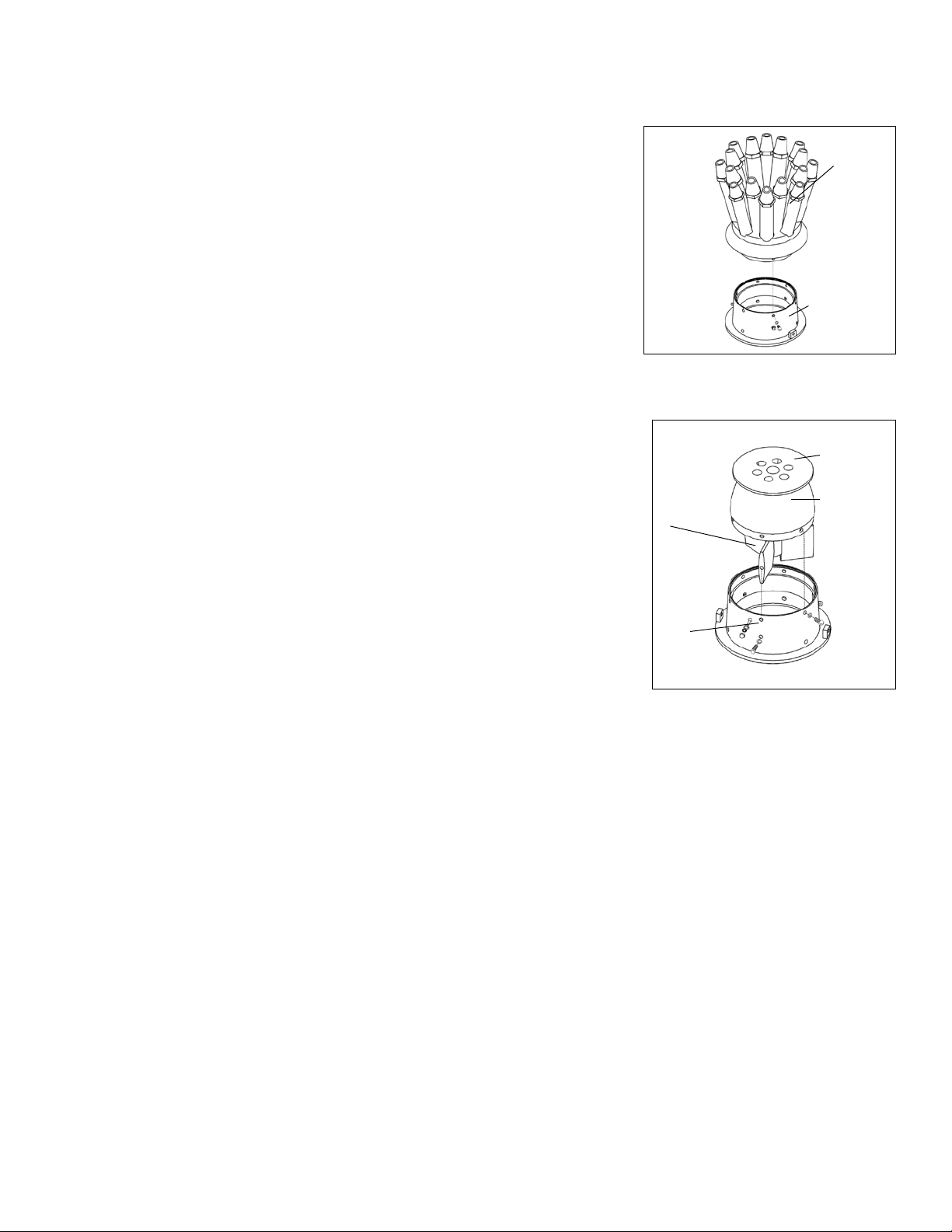

LIGHT

HEX NUTS HEX BOLTS

HEX BOLTS

ANGLED FLOAT

BRACKETS

U-BRACKET

FLOAT

LIGHT

FLAT BRACKET

ANGLED FLOAT

BRACKETS

FLAT

BRACKET

6Aqua Control, Inc. 60 Hz. Select Series 2 Instruction Manual

HEX BOLTS HEX NUTS

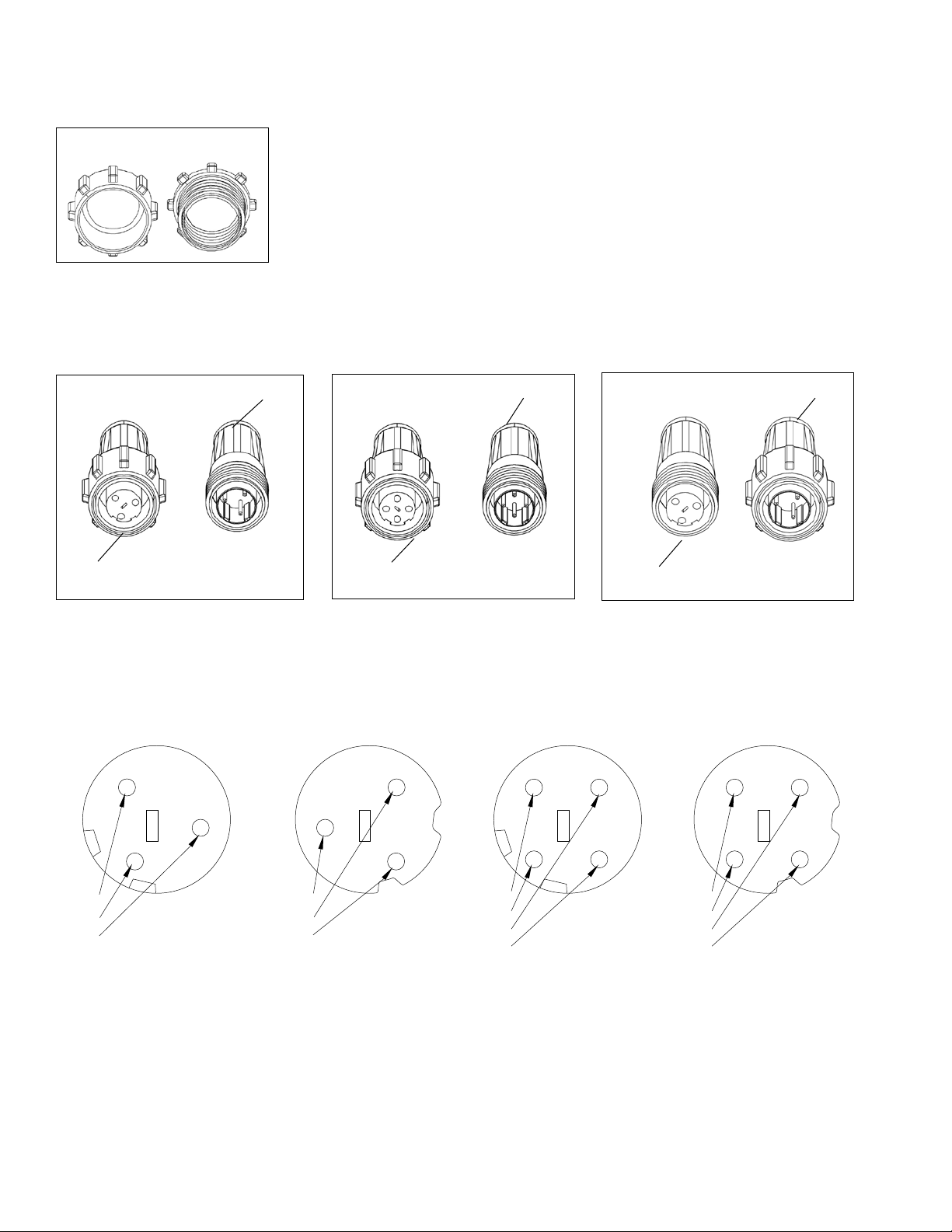

LIGHT SET ASSEMBLY

SELECT SERIES 2 FRESHWATER & SALTWATER

SELECT SERIES 2FRESHWATER

SELECT SERIES 2 SALTWATER

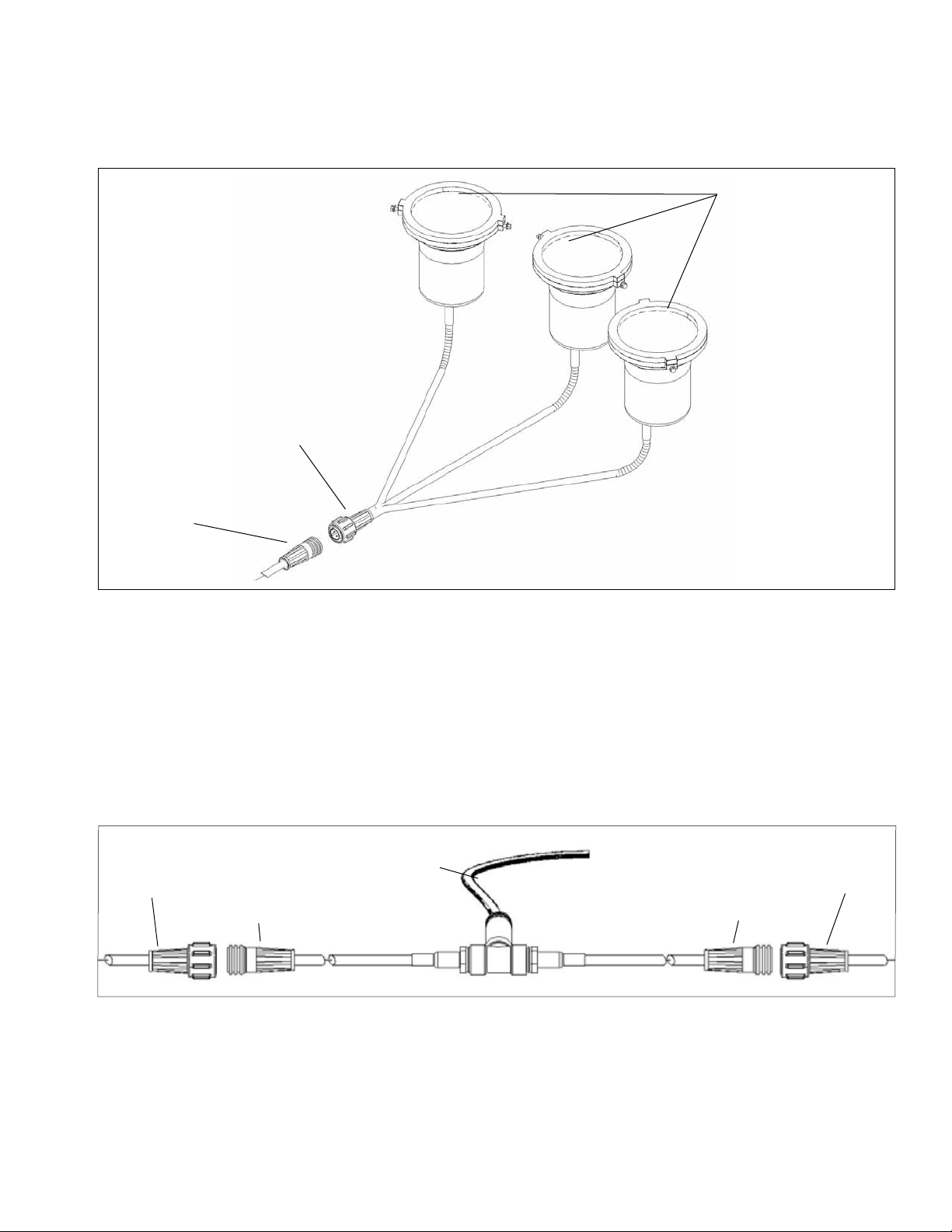

6. Using (2) two hex head bolts, (2) lock washers

and (2) hex nuts, attach the light bracket(s)

to the flat float bracket(s). The slots in

the light U-bracket need to be pointed up

towards the top of the unit. The light

U-bracket is shown attached at the

optimum height if the unit is floating

at the recommended depth. (See flotation

on page 12 for adding weights.) If the unit

is floating higher and is not going to be

weighted down, then the light bracket

will need to be attached lower. The

lights must be 2" below the surface of

the water when the unit is running.

4. Attach a flat float bracket to each set of

angled brackets using a hex head bolt,

lock washer and hex nut at each angled

bracket.

5. Take the light canisters with light brackets

attached out of the box. Stretch out the

light leads to make sure they are not tangled.

1. Open the light set box and remove the plastic

bagcontaining brackets and hardware. The

packagecontains (1) one straight float

bracket, (2) two angled float brackets, (6)

hex head bolts, (6) lock washers and (4) four

hex nuts for each light set.

2. Attach (1) one of the angled float brackets to

the top of the float at any one of the

threaded inserts. Place a lock washer on a

hex bolt and put the bolt through the

middle hole or the hole furthest from the

angle on the bracket. Thread the hex bolt

into the insertand tighten. Repeat this step

for each light in the set, placing the brackets

symmetrically around the float.

7. For saltwater units, all of the threaded

inserts in the floats are plugged by the

factory during assembly except under the

eye bolts. Remove the rubber washer and

attach the bracket by replacing the rubber

washer between the bracket and thefloat.

Plug any remaining inserts with the weight

pins or the 1/2" screws, lock washers,flat

washer and rubber washers. The rubber

washer always goes between the insert and

the hardware.

3. Attach the remaining angled float brackets

to the bottom of the float directly below

the brackets attached in step 2, using the

same hardware as in step 2. Usethesame

hole in step 3.

8. The unit is ready to be floated after

the cable connection(s) have been

made.