GB - 8

• Braking and steering characteristics

• Turning radius and clearances

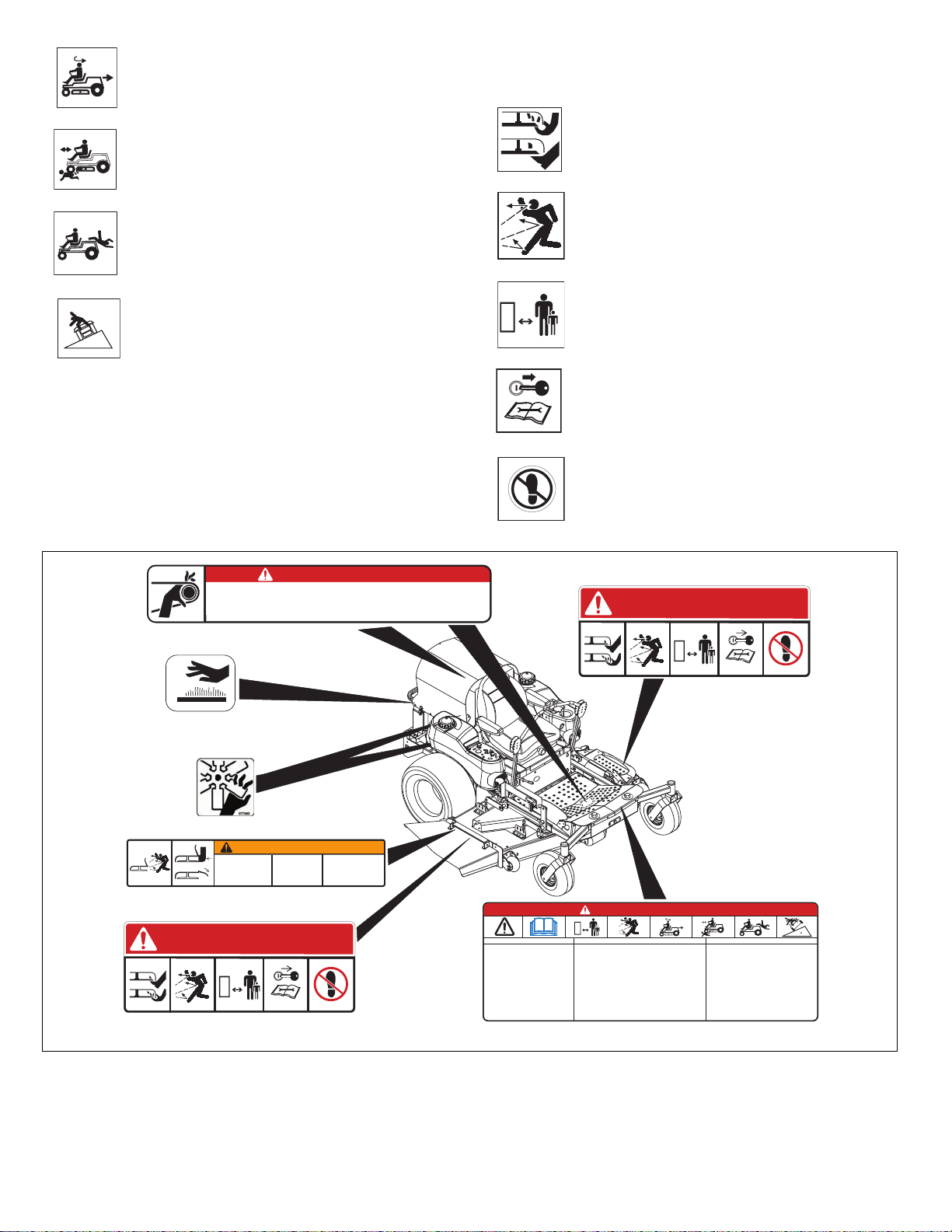

Keep safety devices or guards in place and functioning

properly. NEVER modify or remove safety devices.

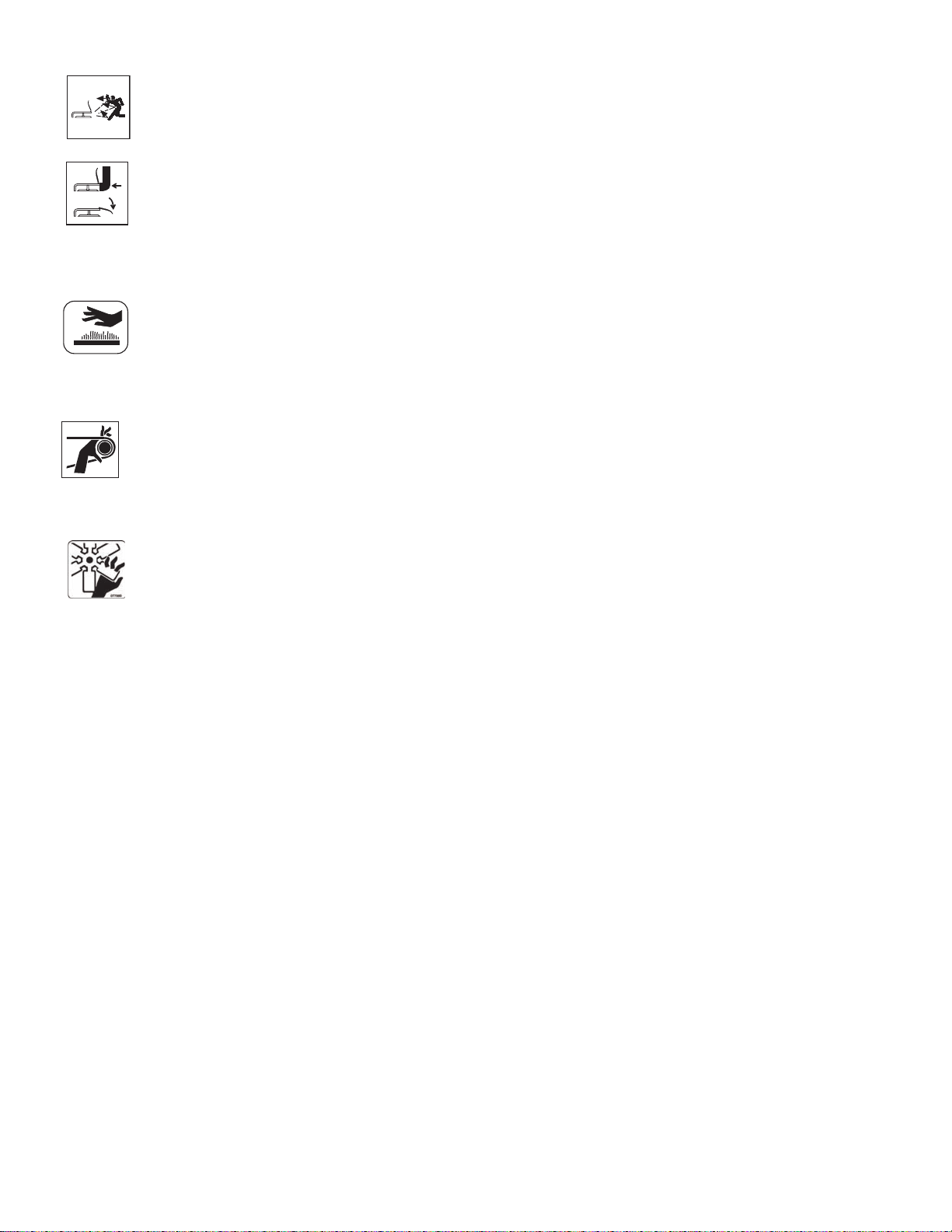

Do not operate without either entire grass catcher or the

discharge guard in place.

Stop engine before removing grass catcher or unclogging

chute.

Ensure Safety Interlock System is functioning properly. DO

NOT operate unit if safety interlock is damaged or disabled.

Start and operate unit only when seated in operator’s

position. Steering control levers must be in neutral, PTO

disengaged and parking brake set when starting engine.

Use care when approaching blind corners, shrubs, trees or

other objects that may obscure vision.

Dust, smoke, fog, etc. can reduce vision and cause an

accident. Mow only in daylight or good artificial light.

Avoid slippery surfaces. Always be sure of your footing.

DO NOT mow on wet grass. Reduced traction could cause

sliding and effect the machine’s stability.

Watch for traffic when operating near or crossing roadways.

Never carry passengers.

DO NOT try to stabilize the machine by putting your foot on

the ground.

Never direct discharge towards persons or property that may

be injured or damaged by thrown objects. Use extreme

caution on gravel surfaces.

Always stand clear of the discharge area.

ALWAYS disengage PTO, stop unit and engine, remove

key, engage parking brake and allow moving parts to stop

before leaving operator’s position.

Never engage PTO while raising attachment or when

attachment is in raised position.

DO NOT operate at too fast a rate. DO NOT change engine

governor settings or over-speed engine. Slow down before

turning.

DO NOT operate in reverse unless absolutely necessary.

ALWAYS look down and behind before and while backing.

Stop and inspect equipment if you strike an object or if there

is an unusual vibration. Repair, if necessary, before

restarting. Never make adjustments or repairs with the

engine running.

Mower blades are sharp and can cut you. Wrap the blade(s)

or wear gloves, and use extra caution when servicing them.

NEVER weld or straighten mower blades.

Rotation of one blade may cause rotation of the other

blades.

Take all possible precautions when leaving unit unattended.

Shut off engine. Remove wire from spark plug and secure it

away from spark plug.

ALWAYS remove key to prevent unauthorized use.

Know the weight of loads. Limit loads to those you can

safely control and the unit can safely handle.

Disengage PTO when attachment is not in use. ALWAYS

turn off power to attachment when travelling, crossing

driveways, etc.

Mow up and down slopes, not across them.

DO NOT operate on slopes of more than 17 degrees.

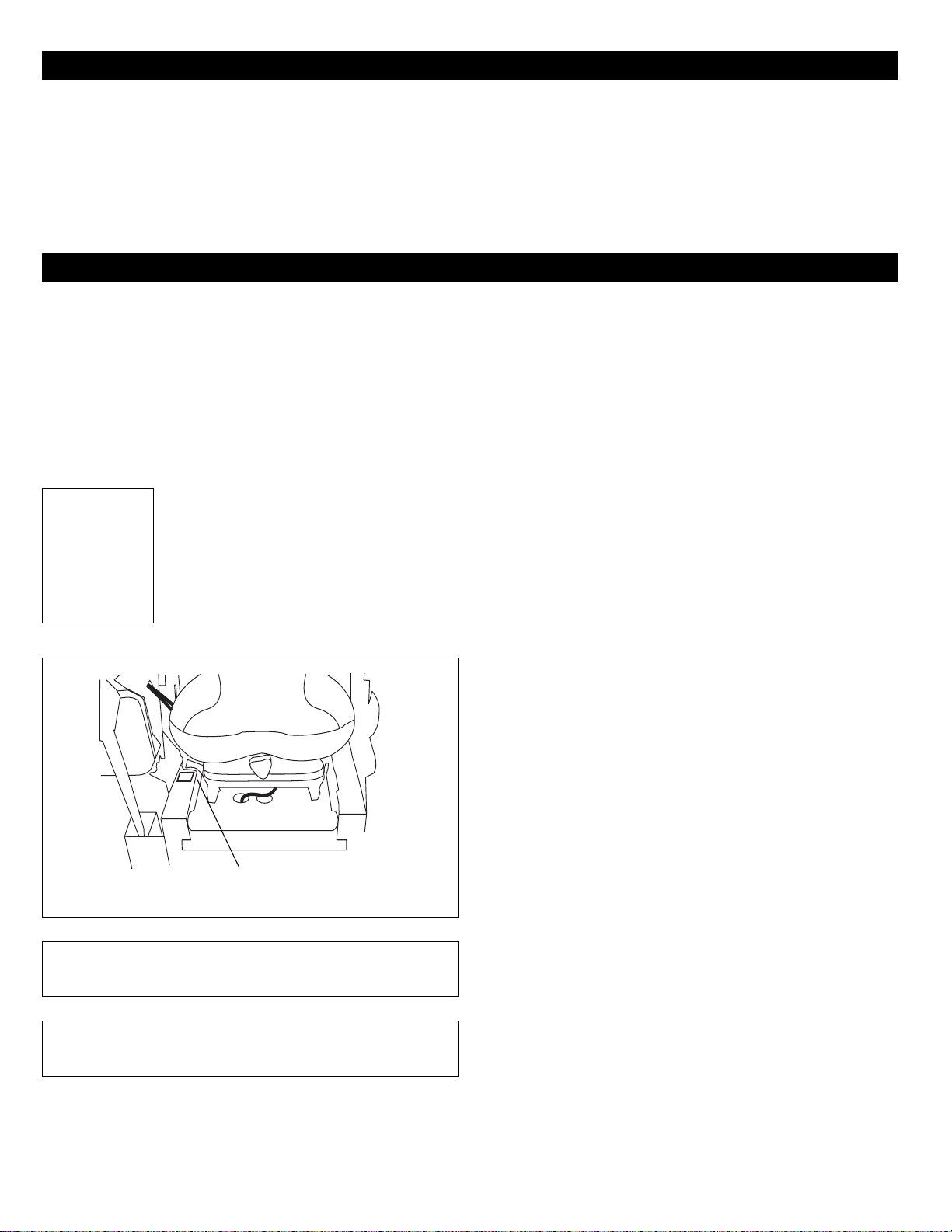

Use of a Rollover Protection System (ROPS) is

recommended for slope operation. See Attachments and

Accessories.

Always wear a seat belt when operating unit using a

Rollover Protection System (ROPS).

Keep all movements on the slope slow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on the slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

If you cannot back up a slope or you feel uneasy on it, do not

mow it.

DO NOT park on slopes unless necessary. When parking on

slope always chock or block wheels. Always set parking

brake.

Use a slow speed. Tires may lose traction on slopes even

though the brakes are functioning properly.

Do not bypass transmission when on a slope.

Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the hitch

point.

Follow the manufacturer’s recommendations for weight

limits for towed equipment and towing on slopes.

NEVER allow children or others in or on towed equipment.

On slopes, the weight of the towed equipment may cause

loss of control.

Travel slowly and allow extra distance to stop.

Use extra care when loading or unloading unit onto trailer or

truck.

Secure unit chassis to transport vehicle. NEVER secure

from rods or linkages that could be damaged.

DO NOT transport machine while engine is running.

ALWAYS turn off power to attachment and shut off fuel

when transporting unit.

Keep unit free of debris. Clean up oil or fuel spills.

This product is equipped with an internal combustion type

engine. DO NOT use unit on or near any unimproved,

forest-covered or brush covered land unless exhaust system

is equipped with a spark arrester meeting applicable local,

state or federal laws. A spark arrester, if it is used, must be

maintained in effective working order by operator.

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use an approved fuel container.

NO smoking, NO sparks, NO flames. ALWAYS allow engine

to cool before servicing.

NEVER fill fuel tank when engine is running or hot from

operation.

NEVER fill or drain fuel tank indoors.