2

aquaguardpoolsystems.com

Safety Information

Safety Guidelines

This manual contains information that is very important

to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following symbols.

DANGER: indicates imminently hazardous situations

which, if not avoided, WILL result in death or serious injury.

WARNING: indicates potentially hazardous situations

which, if not avoided, COULD result in death/serious injury.

CAUTION: indicates potentially hazardous situations

which, if not avoided, MAY result in minor/moderate injury.

NOTICE: indicates important information, that if not

followed, may cause damage to equipment.

NOTE: indicates information requires special attention.

General Safety Information

WARNING: California Proposition 65 - This product may

contain chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm.

Wash hands after handling.

Read all product manuals carefully. Be familiar with

the controls and the proper use of the equipment.

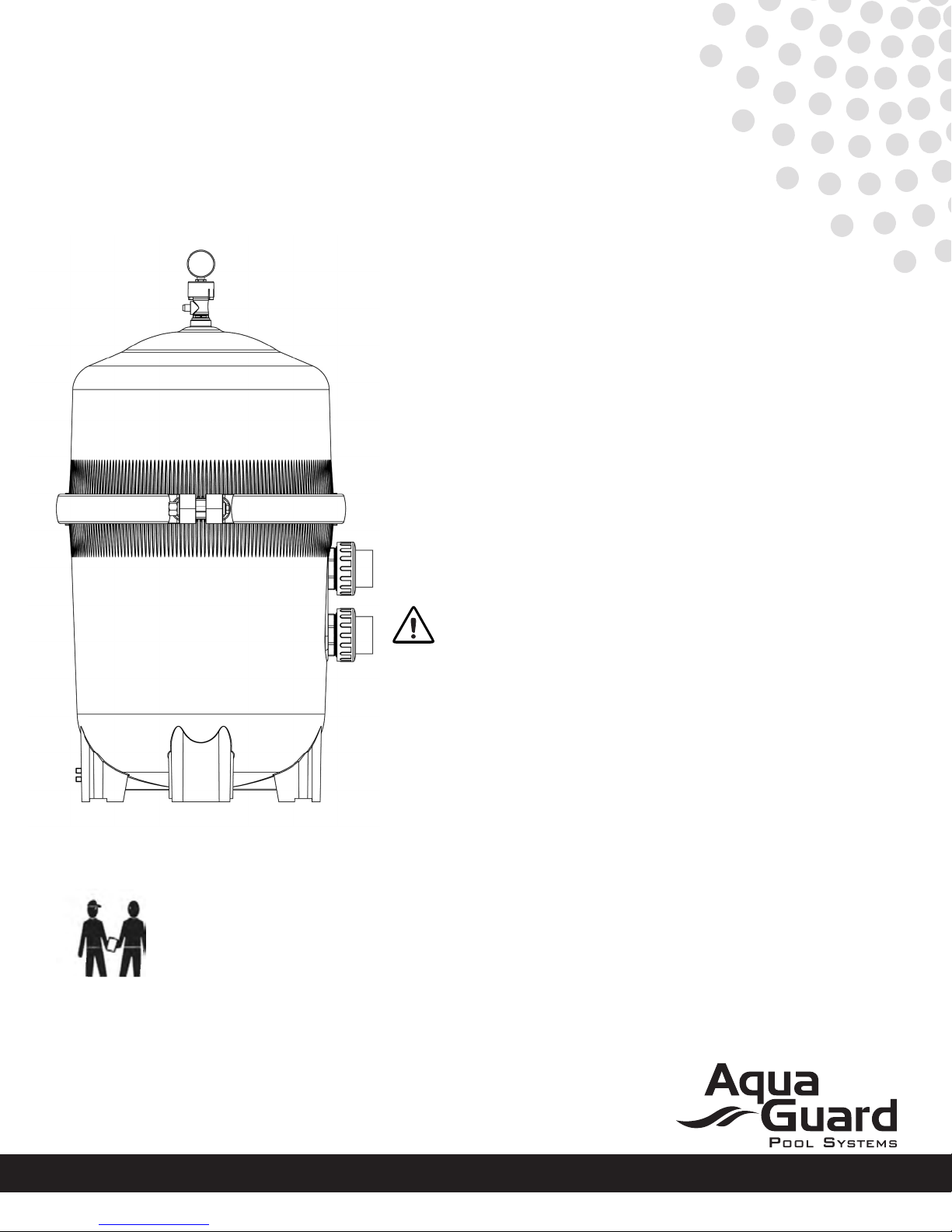

WARNING: This lter operates under high

pressure. Incorrectly installed/serviced

equipment could explode, causing severe injury,

death, and/or property damage.

• Have a trained pool professional perform all pressure tests.

• Never connect lter to compressed air.

• Use lter only in a pool or spa installation.

• Never connect lter to external city/pressurized water.

• Do not connect to pumps that exceed 50 PSI pressure.

• Do not subject lter to pressure in excess of 50 PSI, even

when conducting hydrostatic pressure tests. Pressures

exceeding 50 psi can cause the tank to rupture and could

result in severe injury, death or property damage.

• Air trapped in the system can cause an explosion. Open

the air relief valve to vent all air from the system before

operating or testing the system.

WARNING: Do not use solvents to clean the lter assembly

as they may damage the plastic components.

WARNING: Wear rubber gloves, protective

clothing and eye-wear when using acids and

cleaners. Avoid contact with skin and eyes.

If ingested, call local poison control center.

Observe all warnings and precautions supplied

with acids and cleaners.

WARNING: Risk of electrical shock/electrocution.

• Position the lter drain and air relief valve to

safely direct drainage and purged air or water

away from the pump and other electrical

components. Water discharged from an improperly

positioned assembly can create an electrical hazard that

can cause serious injury, death, and/or property damage.

• Ensure lter installation, grounding and bonding meets

local codes and National Electrical Code (NEC) standards.

All wiring, grounding, and bonding of associated

equipment must be performed by a qualied electrician.

WARNING: Risk of falling and drowning.

• Place equipment 4 ft or more from pool so children cannot

climb over it into pool. Do not stand/play on equipment.

• Never leave lter open/unattended. Secure lter area.

• Keep children away from equipment at all times.

WARNING: This lter is designed to remove debris and

particulates from pool and spa water. Proper water

chemistry MUST be maintained to keep water clean and

avoid spreading diseases. Consult a local pool professional

for more information.

NOTICE: This lter is not designed for backwashing. If unit

is plumbed backwards or backwashed, it will damage the

lter cartridge and will void the warranty.

NOTICE: Attention Installer: This manual contains

important information about the installation, operation

and safe use of this lter. This information should be

furnished to the end user of this equipment.

Table of Contents

Safety Information ............................................................................ 2

Product Specications ..................................................................... 3

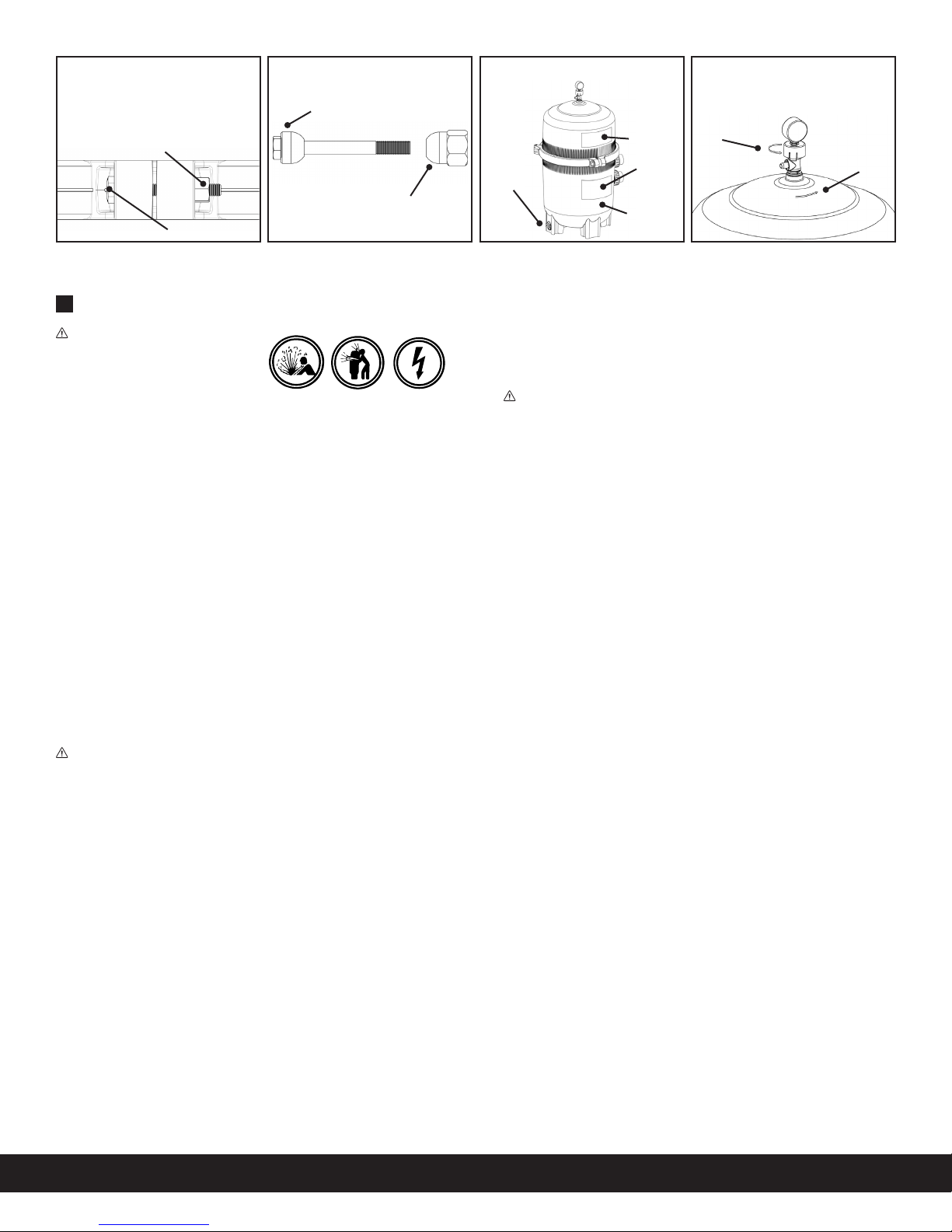

Installation ........................................................................................... 4

Initial Startup ...................................................................................... 5

Maintaining Your Filter .................................................................... 5

Cartridge Cleaning ............................................................................ 6

Filter Re-Assembly .............................................................................. 7

Trouble Shooting ............................................................................... 8

System Inspection ............................................................................. 9

Winterizing .......................................................................................... 9

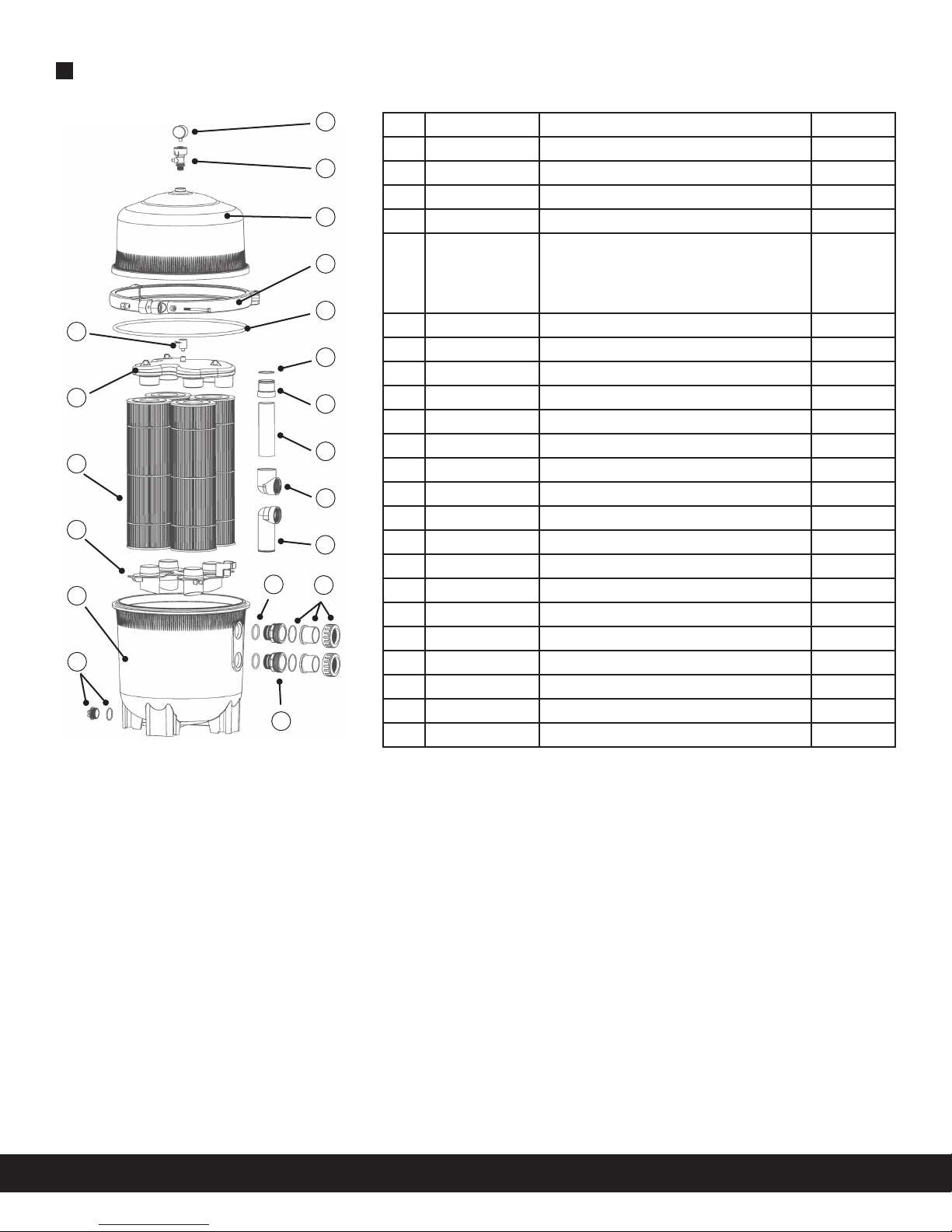

MasterPro Parts Listing .................................................................. 10

Warranty ............................................................................................. 11

SAVE THESE INSTRUCTIONS.