Page 5

INSTALLATION & FITTING

COMMERCIAL STEAM GENERATORS

BJ6-12AkW & BJ18-24AkW

BJ6-12BkW & BJ18-24BkW

NOTE: - Before the installation of this machine, please make sure you read these instructions thoroughly Failure

to install this machine in accordance with the manufacturers recommendations might invalidate the warranty.

Should you have any queries or require technical advice, contact your distributor who will put you in contact

with our technical department. The electricity supply must only be connected to the unit by a suitably qualied

person in accordance with local regulations.

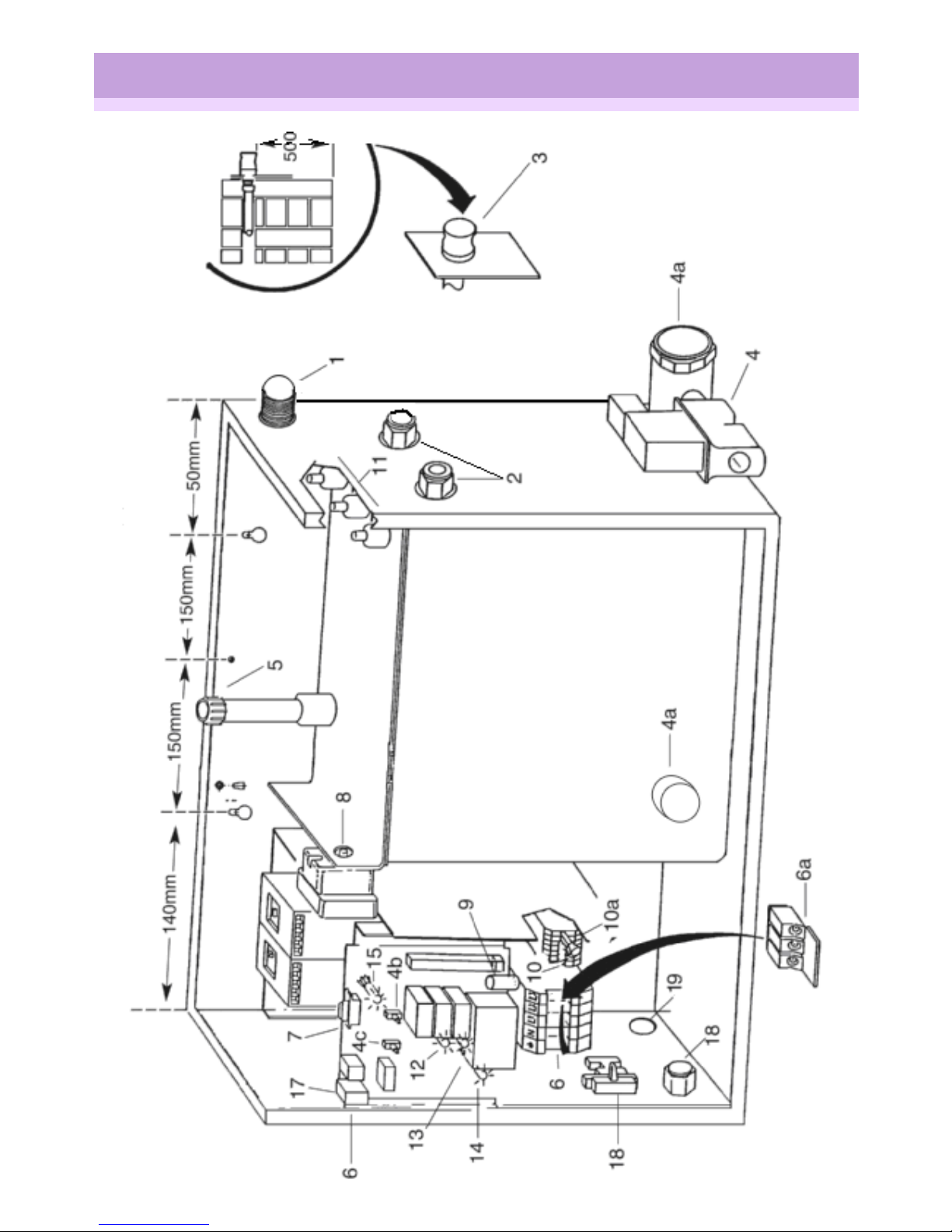

STAGE ONE: - Sighting and Fixing the Generator.

A minimum space of 1100mm for width and 1000mm for height should be allowed, with proper access for

servicing the generator and the descaling cap. (See detail 5 Fig 2) Determine a clean dry place where the steam

generator is to be xed (emphasis on the surface being secure and the unit being properly supported). The unit

is not suitable for installation in a damp or wet area. Screw the generator to the wall, through screw holes (see

dimensions on Fig 2) Make sure the generator is both vertical and horizontally level. Allow 300mm minimum

height from the oor, to leave space for drainage of solids into a container. A minimum space of 400mm from

the cleaning access cap(s) (see Fig 2) from the unit should be permitted for cleaning with the brush provided.

Once the generator has been xed, the anchor screw must be tted to prevent the generator from being

accidentally moved. Should the generator be boxed in, an access door or panel must be tted to allow for easy

access and maintenance of the generator unit without damaging the decoration, you should also make an

allowance for ventilation minimum 100mm x 100mm.

STAGE TWO: - Water Supply

Generally the water supplied from any regional water authority is of sucient quality to use with the Aqua-

Steam generator. Greater care is perhaps required if water is from a well or bore hole particularly if the

iron content is high. Such water should be avoided. If requested the water authority will advise on the scale

content (hardness) of the water supplied. In situation where the water hardness is greater than 100 ppm it is

recommended that a monospheric water softener be incorporated to supply the generator especially if the

unit is to be in frequent use. Alternately inspect the unit for scale after every 100 hours of use and de-scale as

necessary – see descaling instructions. We recommend that a washing machine hose is tted to the 3/4” BSP

male thread of the solenoid valve (detail 1 Fig 2) and connect the other end of the hose to a servicing valve so

the water supply can be isolated. The hose is also useful for ushing the tank and pipe work during maintenance

etc. A minimum water pressure of 0.5 bar and maximum 10.0 bar must be provided for the correct operation of

this machine.

STAGE THREE: - Fitting Steam Outlet

The maximum pipe run must not exceed 20 Mtrs length and must be of 22mm diameter. The pipe work should

be installed in such a way as not to create air locks. Long radius bends should be used or pulled bends to reduce

restriction of steam. The pipe must be adequately lagged to avoid heat loss and condensation of steam. The BJ

18-24 generator has two independent steam outlets; each must be tted as above but totally independent from

each other. When pipe is increased over 10 Metres a higher power setting may be necessary. It is bad practice

and a frequent source of failure to inject essence into the steam pipe(s). Even in very large diameter pipes the

llers and plasticisers used in the essence quickly block the pipe and also back up into the generator.

STAGE FOUR: - Auto-ushing

Connection to the discharge solenoid valve is 1/2” BSP thread and the drain line must be a minimum of 15mm

diameter heat resistant pipe and must have a minimum fall of 1.5 degrees to an open drain, washing machine

trap or similar. Keep the pipe run short with as few bends as possible as it will otherwise ll with scale.

STAGE Five: - In the Cubicle

Fit either the BKW temperature sensor or the AKW cubicle control. The BKW sensor should be tted

approximately 2Mtrs above the oor away from the steam outlet in a safe position. The AKW cubicle control if

tted should be approx l.8mtrs above the oor away from the steam outlet. We recommend that shower type

silicone sealant be used around the stainless steel trim and box assembly of the cubicle control to x the unit to

the wall. Connect plug on lower right hand of attendant control box.