i

TABLE OF CONTENTS

SECTION 1 - FACTORY CONTACT INFORMATION...........................................................................................1

SECTION 2 - SAFETY INFORMATION ................................................................................................................1

SECTION 3 - OWNER QUICK START & RUN.....................................................................................................3

3.1 How Your Digital Nano/Nano+Works ............................................................................................................3

3.2 Control Overview ............................................................................................................................................4

3.2.1 Up and Down Arrows...................................................................................................................4

3.2.2 The Boost Button ......................................................................................................................... 4

3.2.3 Menu and Select Button...............................................................................................................4

3.2.4 Check System Light and Audio Alarm .........................................................................................4

3.3 Normal Display................................................................................................................................................5

3.4 Water Balance & Chemistry Recommendations ............................................................................................5

SECTION 4 - SPECIFICATION AND APPROVALS.............................................................................................6

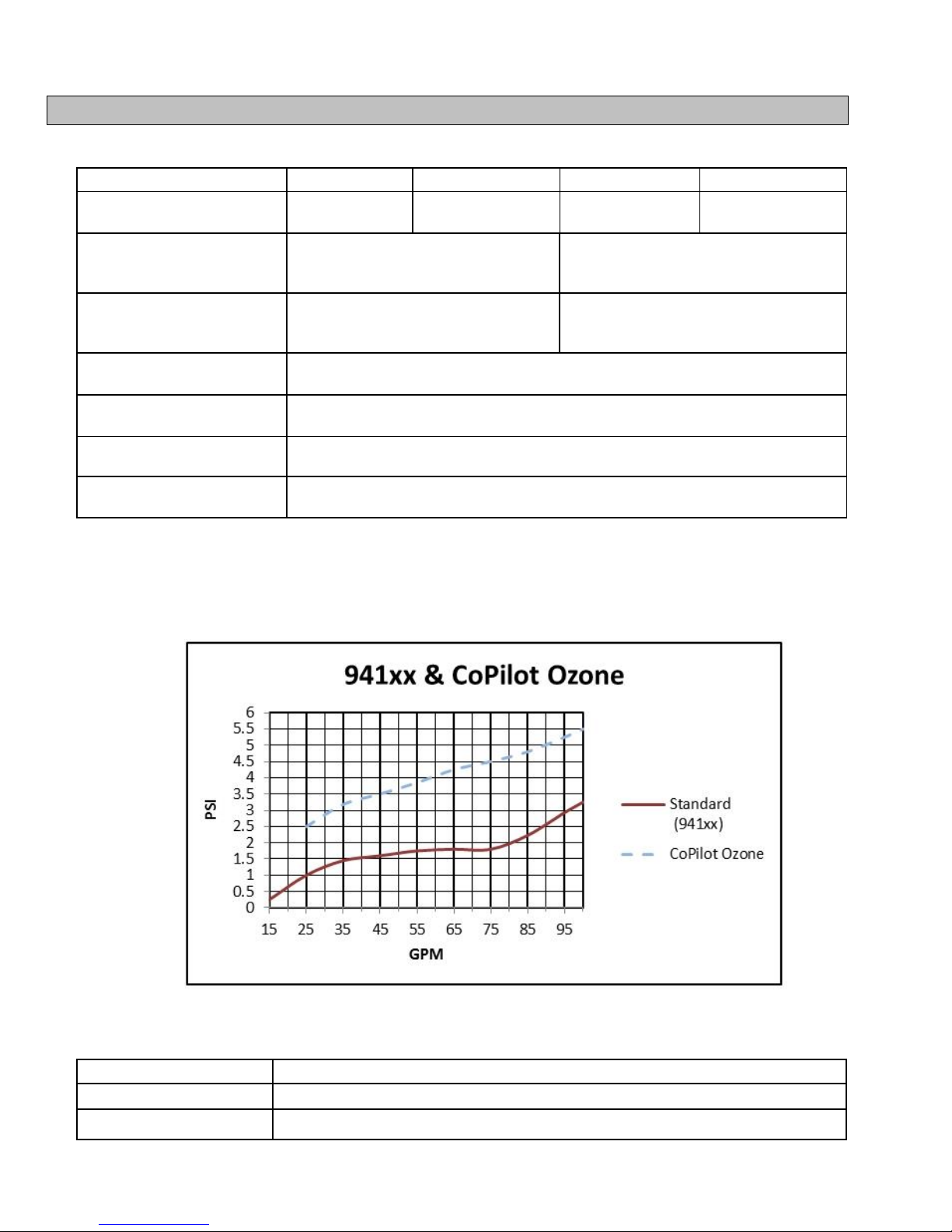

4.1 Specifications..................................................................................................................................................6

4.2 Manifold Pressure Drop Versus Flow .............................................................................................................6

4.3 Agency Approvals...........................................................................................................................................6

SECTION 5 - FEATURES......................................................................................................................................7

5.1 Patented Temperature Compensation............................................................................................................7

5.2 Water Manifolds Assemblies - Available Options...........................................................................................7

5.2.1 Automatic-Flow Bypass Manifold Assembly (#94105 and #94106) ............................................8

5.2.2 CoPilot Manifold Assembly.......................................................................................................... 8

SECTION 6 - MAINTENANCE...............................................................................................................................9

6.1 Fuse Location and Ratings.............................................................................................................................9

6.2 Removing / Inspecting / Cleaning Tri-Sensor...............................................................................................10

6.2.1 Tri-Sensor Assembly Overview..................................................................................................10

6.2.2 Inspect Tri-Sensor......................................................................................................................10

6.2.3 Cleaning Tri-Sensor...................................................................................................................11

6.2.4 Test Tri-Sensor Flow Switch......................................................................................................11

6.3 Servicing the Cell..........................................................................................................................................12

6.3.1 Removal.....................................................................................................................................12

6.3.2 Visual Inspection........................................................................................................................12

6.3.3 Manual Cleaning........................................................................................................................13

6.3.4 Installing.....................................................................................................................................13

6.4 Winterizing ....................................................................................................................................................14

6.5 Spring Start-up..............................................................................................................................................14

SECTION 7 -PROGRAMMING...........................................................................................................................15

7.1 Control Panel................................................................................................................................................15

7.1.1 Button Overview.........................................................................................................................15

7.1.2 Menu Button...............................................................................................................................15

7.1.3 Display Overview .......................................................................................................................15

7.2 Menus ...........................................................................................................................................................16

7.3 Basic Operational Programming...................................................................................................................16

7.3.1 Adjusting the Chlorine Output %................................................................................................16

7.3.2 Boost or Super Boost.................................................................................................................17

7.3.3 Chlorine Mode............................................................................................................................17

7.3.4 Chlorine % Adjustment Procedure.............................................................................................17

7.4 Test Pool Pilot (Diagnostic Menu) ................................................................................................................18

7.5 View Setup....................................................................................................................................................18