Contents

1Safety Information ..................................................................................................... 5

1.1 Intended Use ...................................................................................................... 5

1.2 Statutory Obligations............................................................................................. 5

1.3 Electrical Safety .................................................................................................. 5

1.4 Installation Safety ................................................................................................ 6

1.5 Post-Installation Safety .......................................................................................... 6

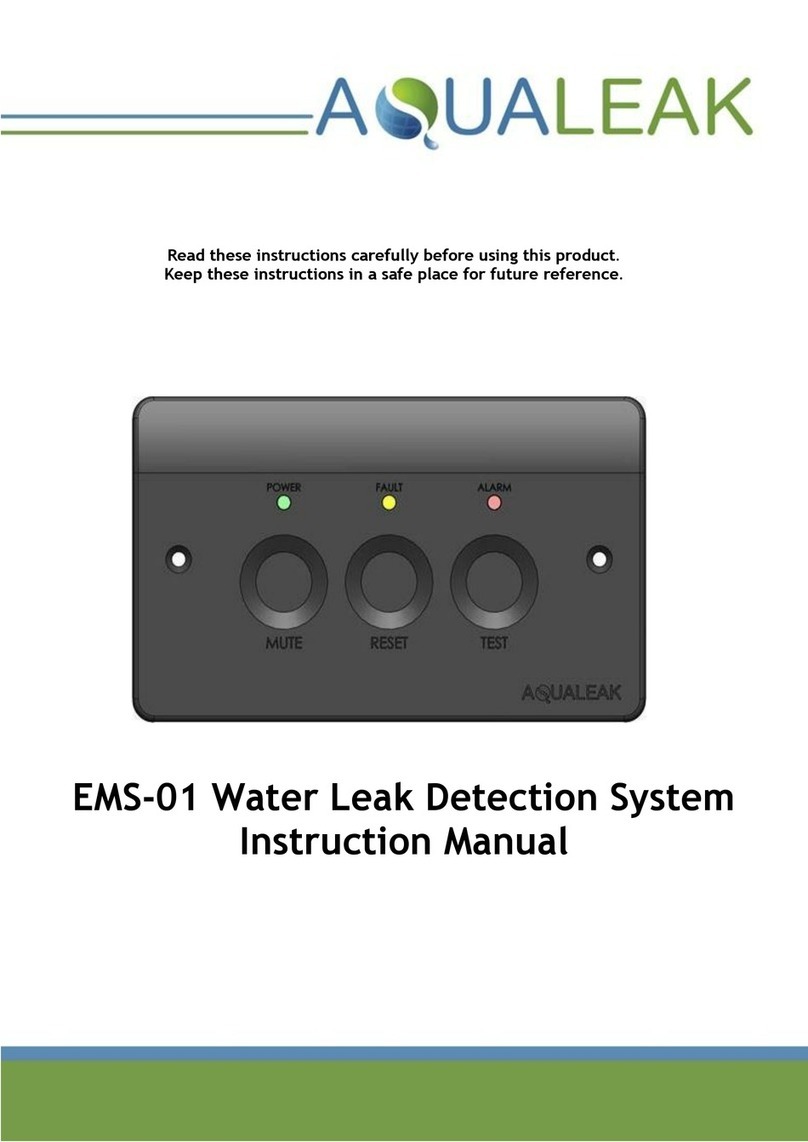

2Product Overview ...................................................................................................... 7

2.1 Technical Specifications ......................................................................................... 8

2.2 Input-Output Connections ....................................................................................... 9

3Installation .............................................................................................................10

3.1 Unit Installation.................................................................................................. 10

3.1.1 Mounting ....................................................................................................... 10

3.1.2 Power Connections ........................................................................................... 10

3.2 Valve/Flow Meter Assembly.................................................................................... 11

3.3 Sensors and Relays .............................................................................................. 12

3.3.1 Sensor / Relay Connections ................................................................................. 13

3.4 Ancillary Devices................................................................................................. 17

3.4.1 Signalling to an Ancillary Device ........................................................................... 17

3.4.2 230V Output to an Ancillary Device ........................................................................ 17

4Menu Settings ..........................................................................................................20

4.1 Passcode Protection ............................................................................................. 20

4.2 Contrast........................................................................................................... 20

4.3 Maximum Flow Rate ............................................................................................. 20

4.4 Maximum Time of Flow Rate................................................................................... 21

4.5 Holiday Mode Time .............................................................................................. 21

4.6 Valve Exercise Frequency ...................................................................................... 21

4.7 Sensor Sensitivity ................................................................................................ 22

4.8 Valve Type........................................................................................................ 22

4.9 K Factor ........................................................................................................... 22

4.10 Valve Voltage .................................................................................................... 23

5Operation ...............................................................................................................24

5.1 Monitor Mode..................................................................................................... 25

5.2 Fault Mode........................................................................................................ 25

5.3 Alarm Mode....................................................................................................... 26

5.4 Manual Override ................................................................................................. 26

5.4.1 Manual Open................................................................................................... 26

5.4.2 Manual Close .................................................................................................. 26

6Maintenance ...........................................................................................................27

6.1 Cleaning........................................................................................................... 27

7Troubleshooting .......................................................................................................28

8Warranty................................................................................................................29