Quartz bath with overflow filler installation instructions Page 5

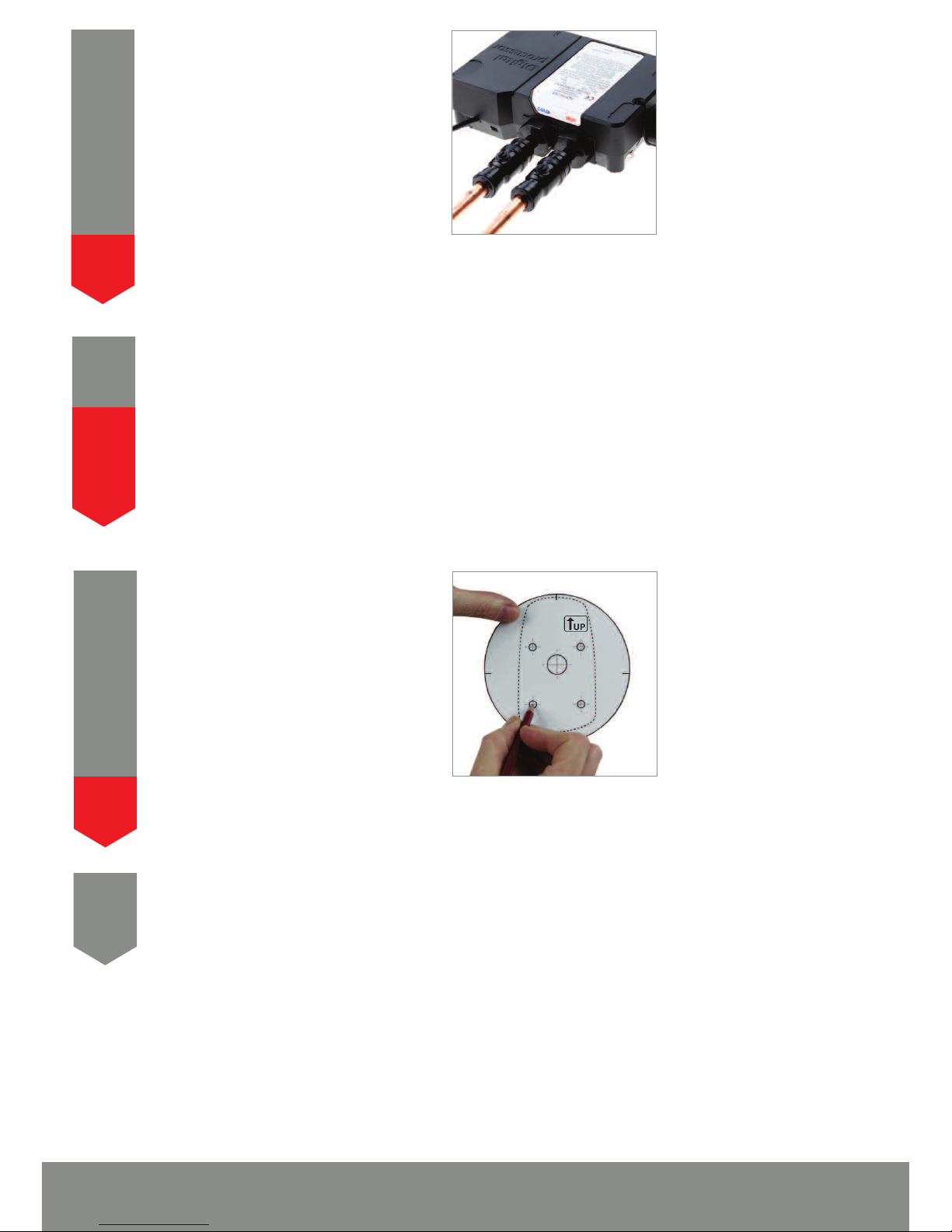

Cables which are chased into the wall must be protected by a suitably sized conduit or sheathing to allow for

removal in the event of service and maintenance purposes.

Surface mounted cables must also be protected by a suitable approved conduit, even in a loft, where there may

be a risk of damage from vermin.

The power lead must only be replaced by the manufacturer or his accredited agent.

The user control is supplied from a safety low voltage source.

This product is suitable for domestic use only.

Quartz Digital is supplied with a 5 year guarantee.

Installation of Digital Gravity Pumped pro essor (for gravity stored

systems)

The Quartz Digital Gravity Pumped Bath system is designed to operate up to a maximum static pressure of

100kPa ((1 bar)(10 metres head)(14.5psi)).

Under no circumstances must the pumped processor be connected directly to the water main or in line with

another booster pump.

The minimum actual capacity of the cold water storage cistern should be not less than 225 litres (50 gallons).

The capacity of the hot water cylinder must be capable of meeting anticipated demand.

Installation of Digital HP/Combi pro essor (for balan ed high pressure

and unvented systems, ombination boiler systems and separately

pumped gravity systems)

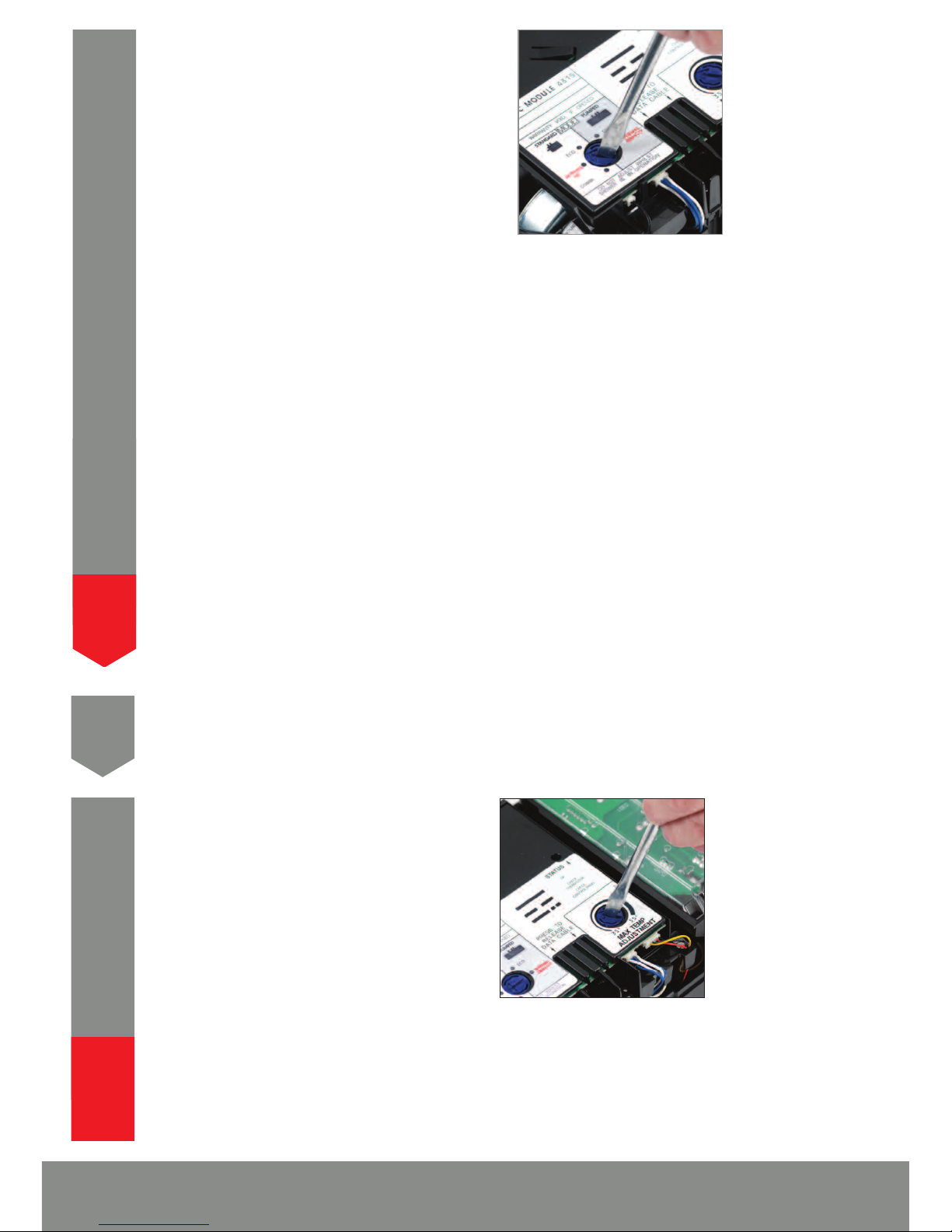

Pressures: The Quartz Digital HP/Combi Bath system is designed to operate up to a maximum static pressure of

700kPa ((7 bar)(100psi)). Where pressures are likely to exceed 700kPa ((7 bar)(100psi)), a pressure reducing valve

must be fitted to the incoming mains supply. A setting of 400kPa ((4 bar)(60psi)) is recommended. It should be

noted that daytime pressures approaching 600kPa((6 bar)(80psi)) can rise above the stated maximum overnight.

Spe ial notes for ombination boiler systems

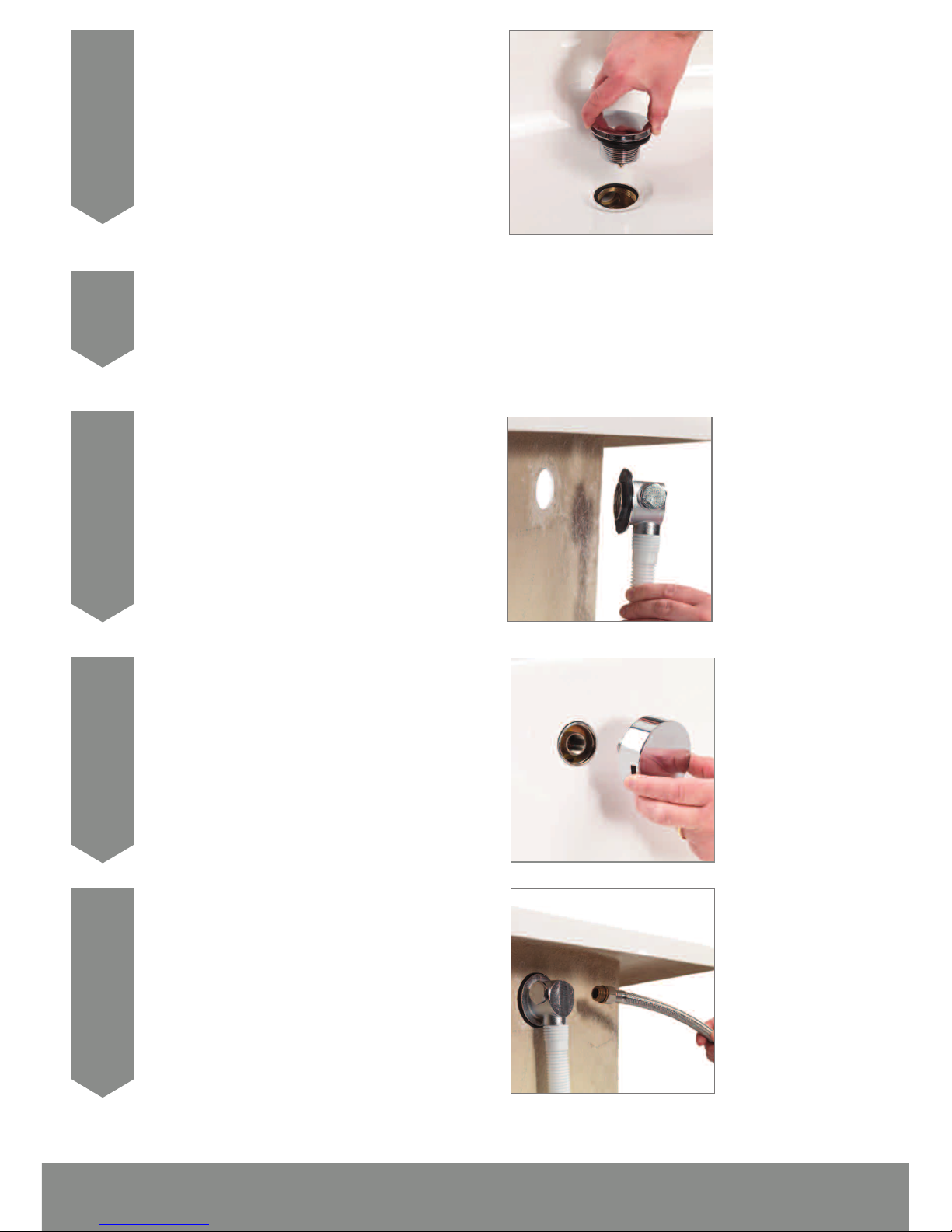

The appliance must have a minimum domestic hot water rating of 24kW (80,000BTU) and be of the type fitted

with a fully modulating gas valve.

If in any doubt, please contact the appliance manufacturer before installation commences.

P EASE NOTE: DUE TO PERFORMANCE CHARACTERISTICS OF COMBINATION BOI ERS, SEASONA IN ET

TEMPERATURE CHANGE WI AFFECT THE PROCESSOR OUT ET F OW RATE RESU TING IN VARYING BATH F OW

RATE AND F OW CONTRO RANGE. IN ET TEMPERATURE CHANGE MAY A SO CAUSE THE TEMPERATURE ED’S

TO F ASH; THIS IS NOT NECESSARI Y CHANGING THE OUT ET TEMPERATURE.