MΩ/cm30 to 19.99 0.01

uS/cm3

0 to 2.000 0.01

0 to 20.00 0.1

0 to 200.0 0.1

0 to 5000 1.0

mS/cm30 to 20.00 10

0 to 200.0 50

Section I - Specifications Page 2

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section I - Specifications

pH ORP Conductivity Flow

Display 2 x 16 alpha-numeric LCD display

Power Requirements 4 to 20mA, Loop Powered, 16 to 32 VDC

Flow: 0 to 9999 with

selectable

flow rate units

pH: 0.01 to 14.00 ORP: -1999 to +1999mV

Volume: 0 - 999 with Auto Range

Measuring Range (Dependent on sensor)

Flow rate units: Gallons (GP), Cubic

Temp: 0 to 100°C or Temp: 0 to 100°C or

Feet (CF), Liters (LP), Cubic Meters

32° to +212°F 32° to +212°F (

CM), custom by entering factor

related to Gallons

Time units: Seconds (S), Minutes (M)

Temp: 0 to 100°C or 32° to +212°F

Hours (H)

Automatic or Manual

Temperature Automatic or Manual Not required User selectable temperature Not required

Compensation 0 - 100°C (32° to +212°F)

compensation slope 0.0 to 10.0%/°C.

0 to 100°C (32° to +212°F)

Temperature Unit °C or °F Not required

Temperature Sensor User selectable: 300ΩNTC Thermistor, 3000ΩNTC Thermistor or Pt. 1000 RTD Not required

Auto-Calibration Manual Calibration Dry Calibration

Calibration Modes Manual Calibration Temperature Calibration Sample Calibration K factor Input

Temperature Calibration Temperature Calibration

Ambient Conditions Temperature: -20°C to +60°C or -4°F to +140°F Humidity: 0 to 90% RH (non-condensing)

Sensor to Transmitter Differential Sensor: 3000 ft 300 ft 2000 ft

Distance Combination Sensor: 10 ft

Analog Output 4 to 20mA

Isolated Output, Range expand 0 to 100% of full scale (min segment 10% of full scale), max. load 800Ω

Memory Back-up All user settings are retained indefinitely in memory (EEPROM)

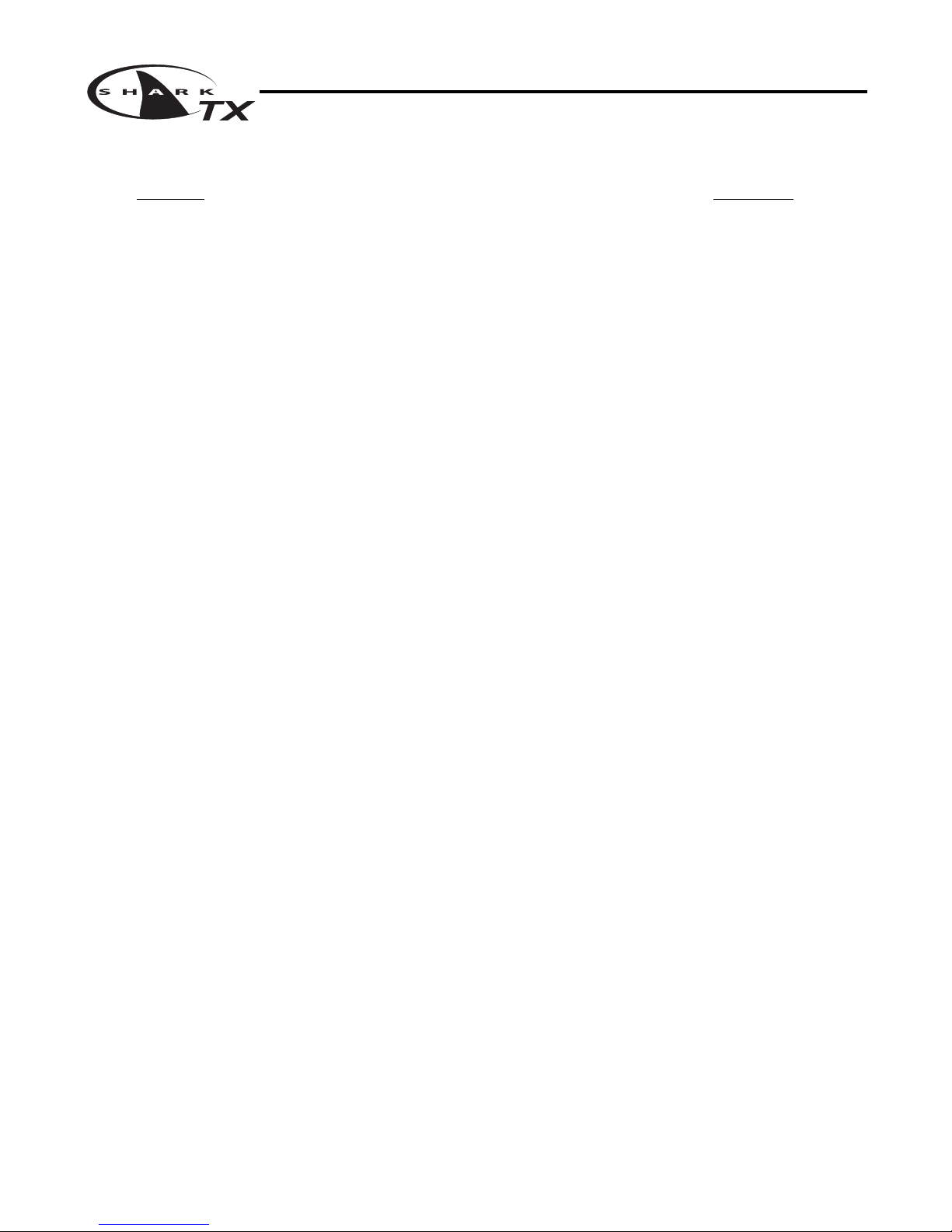

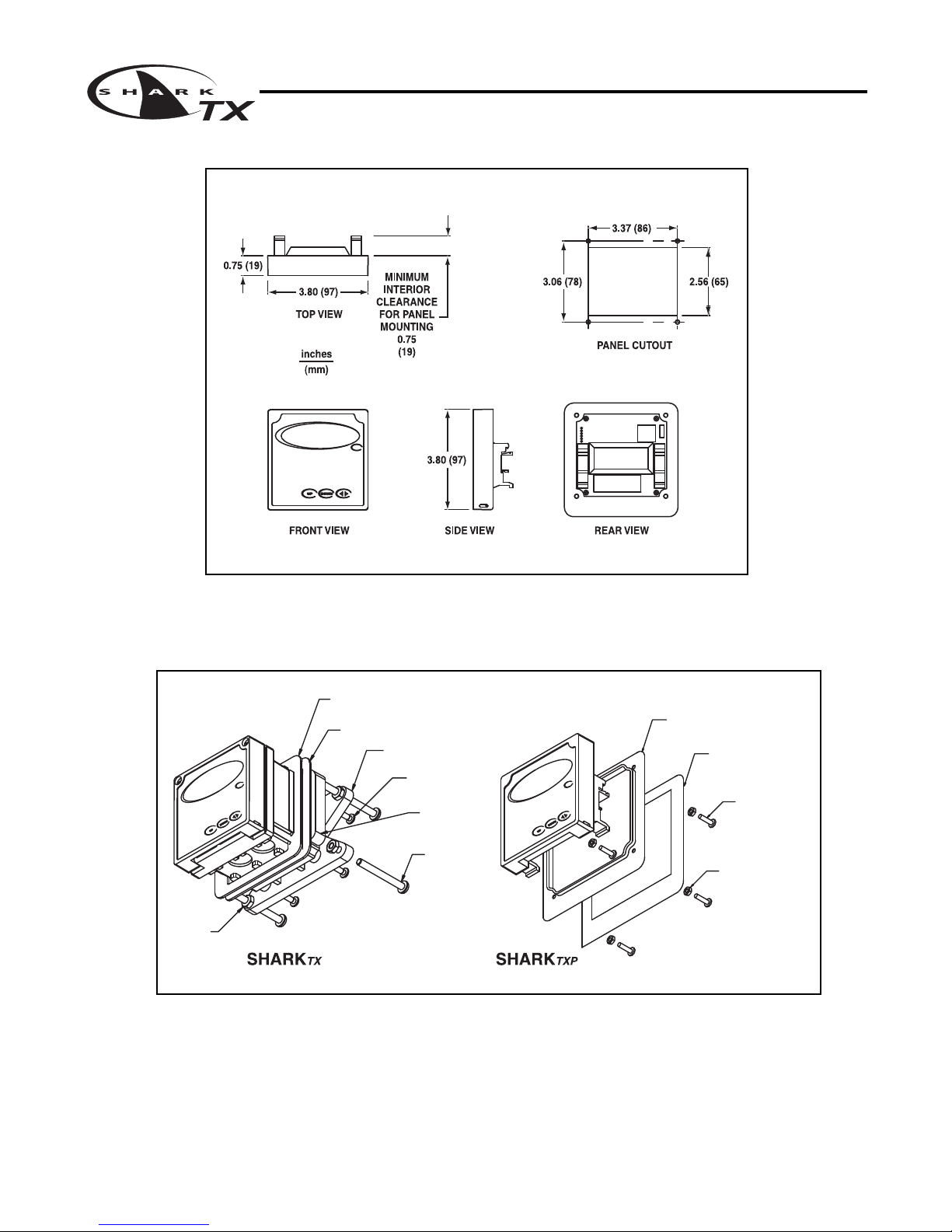

SHARKTX Enclosure: NEMA 4X, 1/4 DIN, polycarbonate enclosure with two 1/2”conduit holes

Mechanical SHARKTXP Enclosure: NEMA 4X front panel, 1/4 DIN, polycarbonate

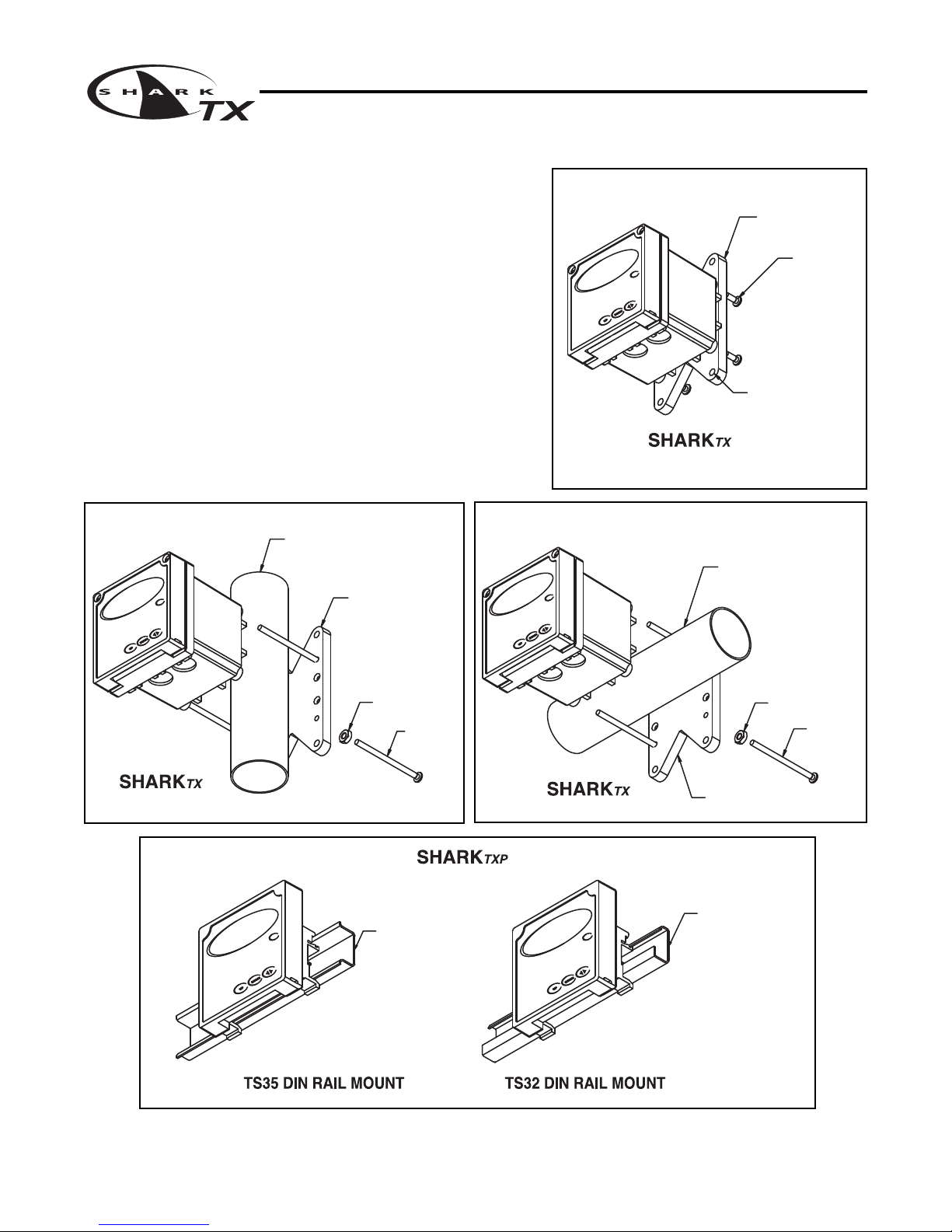

SHARKTX Mounting: Universal Mounting kit for surface, pipe and panel mount included

SHARKTXP Mounting: Panel and DIN rail mount included

Sensor Input Probe: -600 to +600mV Probe: -1999 to +1999mV Cell: 0 to 9999ΩPaddle: 0 to 2000Hz

Temp. Sensor: 0 to 9999ΩTemp. Sensor: 0 to 9999ΩTemp. Sensor: 0 to 9999Ω

Invalid Entries Invalid entries cannot be stored

Manual Test Mode Process value can be simulated with arrow keys to verify correct setup of output

Output Hold 4 to 20mA output is placed on hold when the transmitter is in Menu mode

Recall data from last

Recall data from last calibration, calibration mode, calibration, calibration buffer

Calibration Data 1st & 2nd accepted buffer value and probe mV output, accepted value, and cell Recall store K factor.

calibration temperature, calibration slope, and probe resistance, calibration

efficiency temperature

Auto Return User selectable auto return if the transmitter is left in menu mode for more than 10 min.

Display Damping User can select rate at which the transmitter updates display. Enables display damping of unstable process

Net Weight SHARKTX: 0.71 lbs (0.32 kg)

SHARKTXP: 0.25 lbs (0.12 kg)

Approvals ULC (pending)