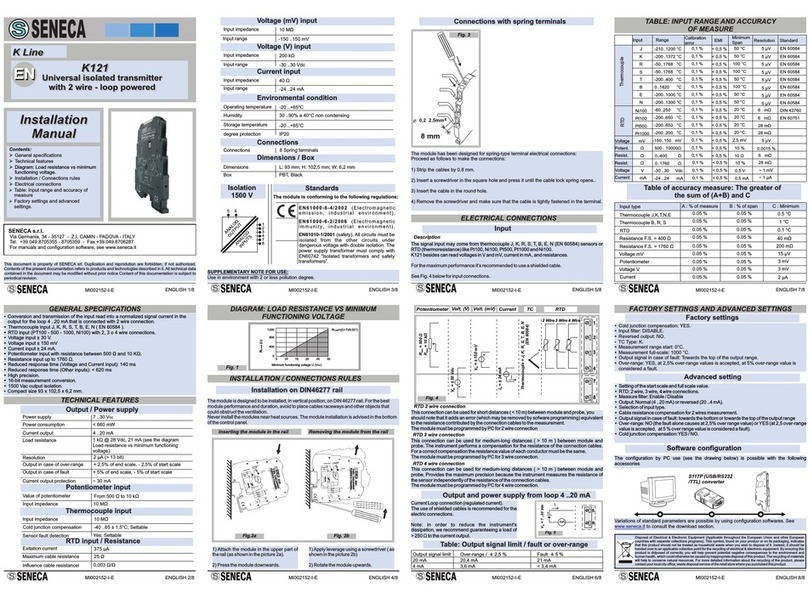

LED indications on the frontal panel

LED Meaning

Rapid flashing

3 pulses/sec.

Internal fault

Slow flashing

1 pulse/sec.

DIP-switch setting error (full scale and start range limits)

Steady light RTD connection wire fault.

Measurement out of range, 3 wire resistance out of range.

rd

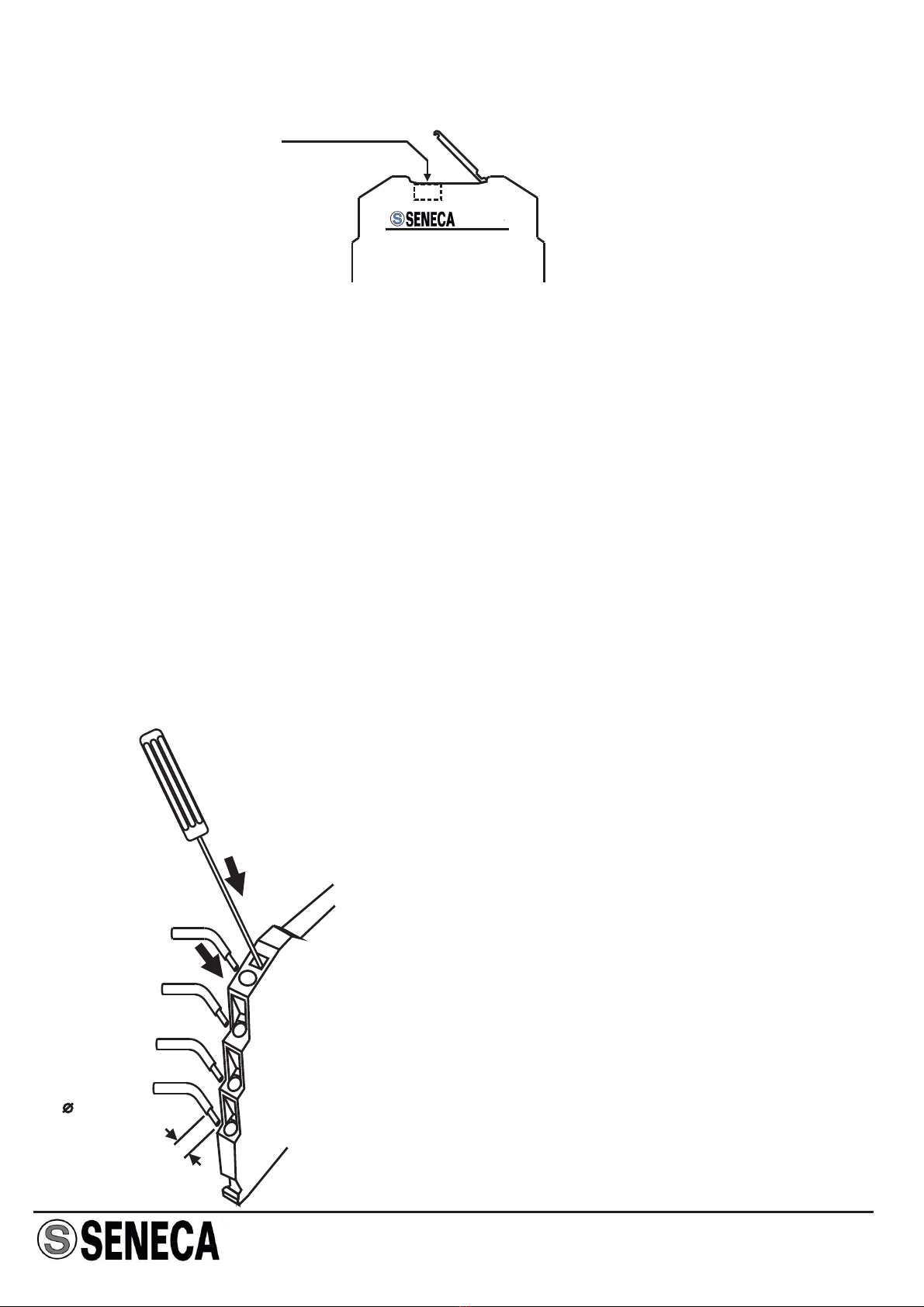

Output

Current loop connection (regolated current).

The use of shield cables is recommended for the electronic connections.

Note: in order to reduce the instrument's dissipation, we recommend guaranteeing a load

of > 250 n

Ωto the curre t output.

15

6 2

3

4

OUTPUT

INPUT

+

-

U

Iout

RLoad

MI00124 -E2 ENGLISH - 8/8

Disposal of Electrical & Electronic Equipment (Applicable throughout the European Union and other

European countries with separate collection programs)

This symbol, found on your product or on its packaging, indicates that this product should not be treated as

household waste when you wish to dispose of it. Instead, it should be handed over to an applicable

collection point for the recycling of electrical and electronic equipment. By ensuring this product is

disposed of correctly, you will help prevent potential negative consequences to the environment and

human health, which could otherwise be caused by inappropriate disposal of this product. The recycling of

materials will help to conserve natural resources. For more detailed information about the recycling of this

product, please contact your local city office, waste disposal service or thè retail store where you

purchased this product.

SENECA s.r.l.

Via Austria, 26 - 35127 - PADOVA - ITALY

Tel. +39.049.8705355 - 8705359 - Fax +39.049.8706287

This document is property of SENECA srl. Duplication and reprodution are forbidden, if not authorized. Contents of the

present documentation refers to products and technologies described in it. All technical data contained in the document

may be modified without prior notice Content of this documentation is subject to periodical revision.