Mounting and operating instructions

CONTOIL®

VZF II / VZFA II, DN 15 –50

Table of Contents

1Safety.............................................................................................................................2

1.1 Intended Use ............................................................................................................................................................ 2

1.2 Notes on safety rules and symbols.................................................................................................................. 2

1.3 Safety rules and precautions .............................................................................................................................. 3

1.4About the operating manual.............................................................................................................................. 3

2Product description .....................................................................................................4

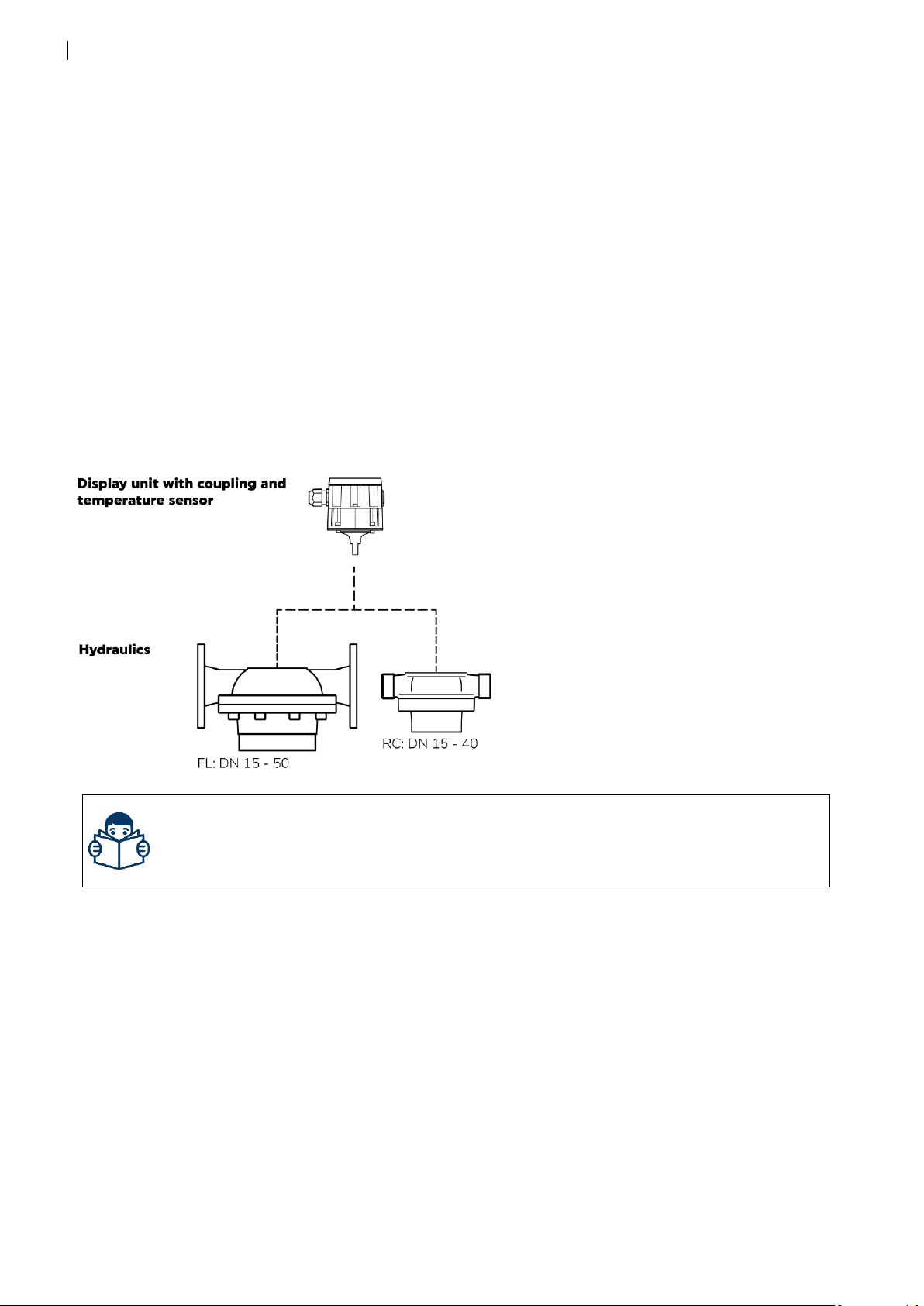

2.1 Flow meter configuration .................................................................................................................................... 4

3Scope of delivery an accessories................................................................................5

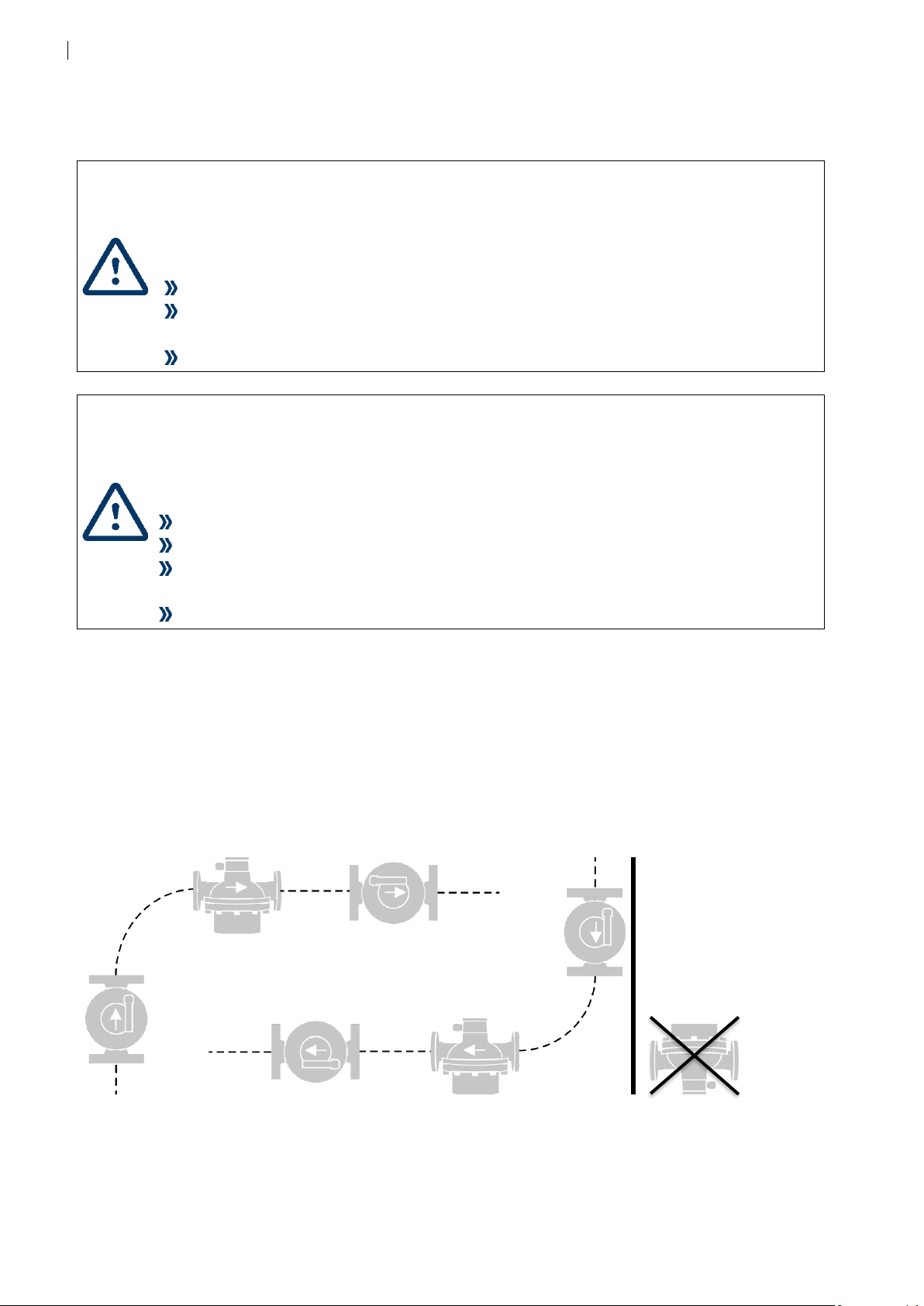

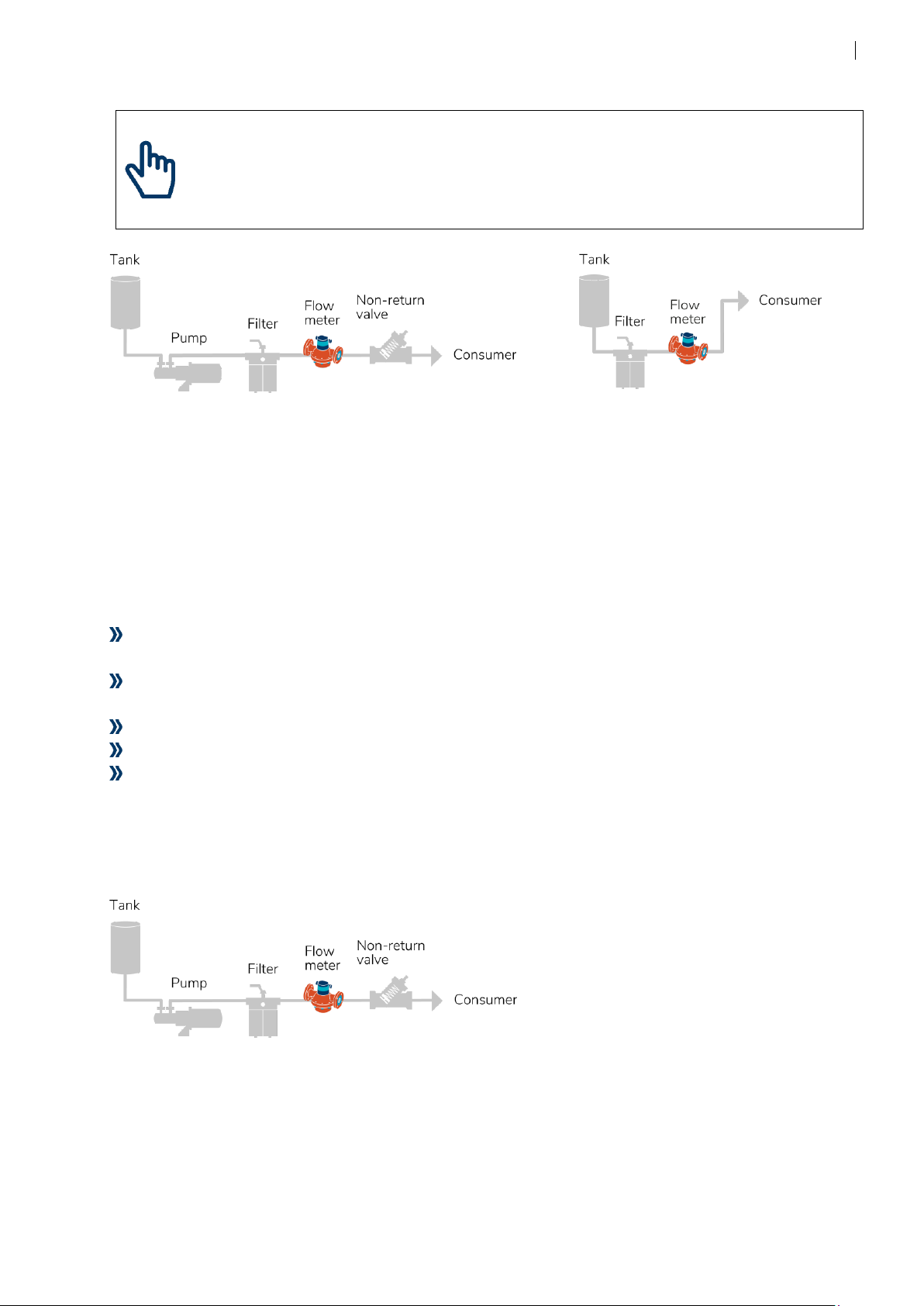

4Mounting ......................................................................................................................6

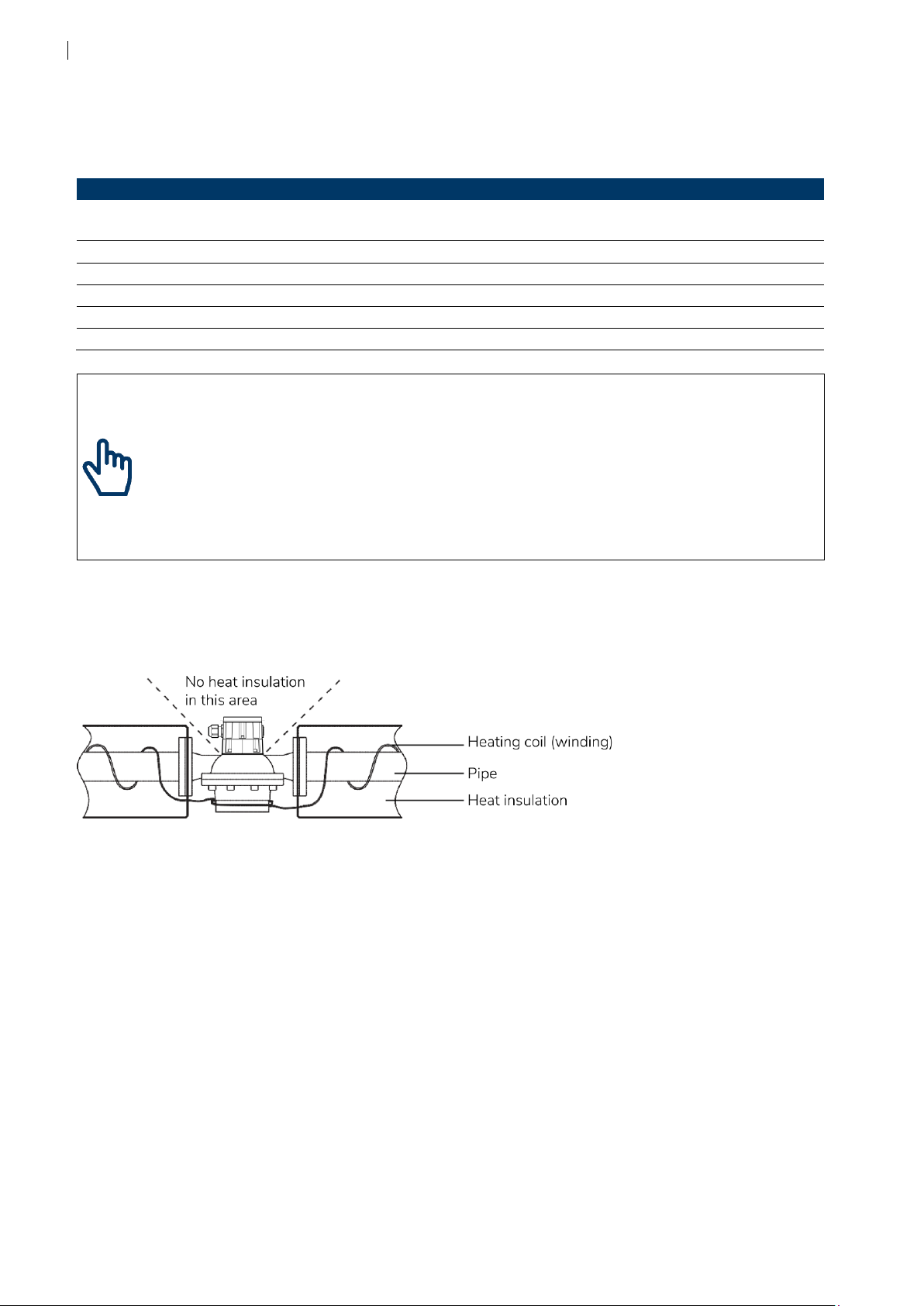

4.1 Mechanical installation.......................................................................................................................................12

4.2 Electrical Installation............................................................................................................................................14

4.3 Engineering notes.................................................................................................................................................15

5Handling and operation............................................................................................16

5.1 Commissioning......................................................................................................................................................17

5.2 Display and operation.........................................................................................................................................17

5.3 Parameterizing.......................................................................................................................................................18

5.4 Main Menu..............................................................................................................................................................18

5.5 Setup menu structure..........................................................................................................................................20

5.6 Output assignment settings .............................................................................................................................22

5.7 Description of menu items................................................................................................................................24

6Maintenance and Repair ...........................................................................................27

6.1 Calibration ...............................................................................................................................................................27

6.2 Service maintenance............................................................................................................................................27

6.3 Maintenance...........................................................................................................................................................29

6.4 Spare parts ..............................................................................................................................................................30

7Troubleshooting.........................................................................................................31

7.1 Error messages VZF II / VZFA II .......................................................................................................................32

7.2 Alarm messages VZF II / VZFA II.....................................................................................................................33

8Decommissioning, Dismantling and Disposal ........................................................34

8.1 Decommissioning.................................................................................................................................................34

8.2 Dismantling.............................................................................................................................................................34

8.3 Return of materials...............................................................................................................................................35

8.4 Disposal....................................................................................................................................................................35

9Technical data ............................................................................................................36

9.1 Hardware characteristics....................................................................................................................................36

9.2 Parameterizing the VZF II / VZFA II outputs...............................................................................................38

10 Appendix.....................................................................................................................43

10.1 Dimensional drawings.........................................................................................................................................43

10.2 Default settings VZF II / VZFA II ......................................................................................................................44

11 Certificates..................................................................................................................47