2 VI 14-419 def 07.2017

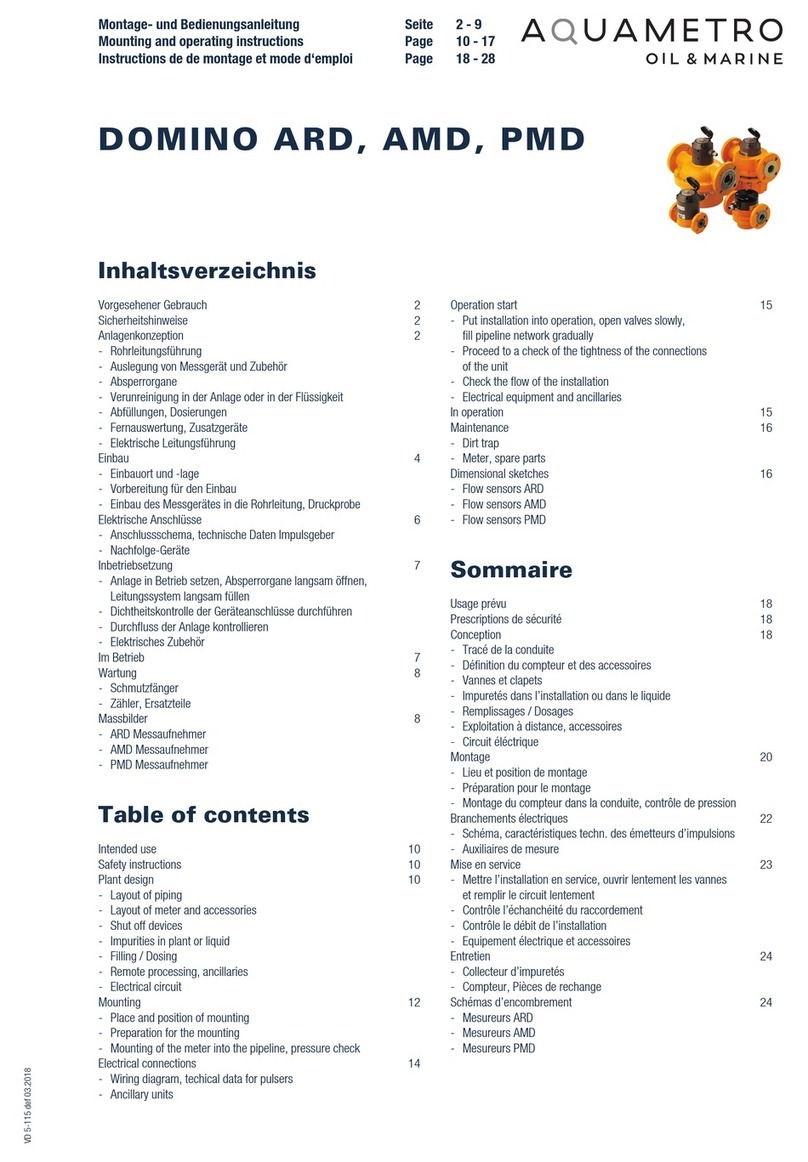

Inhaltsverzeichnis Index of contents Sommaire

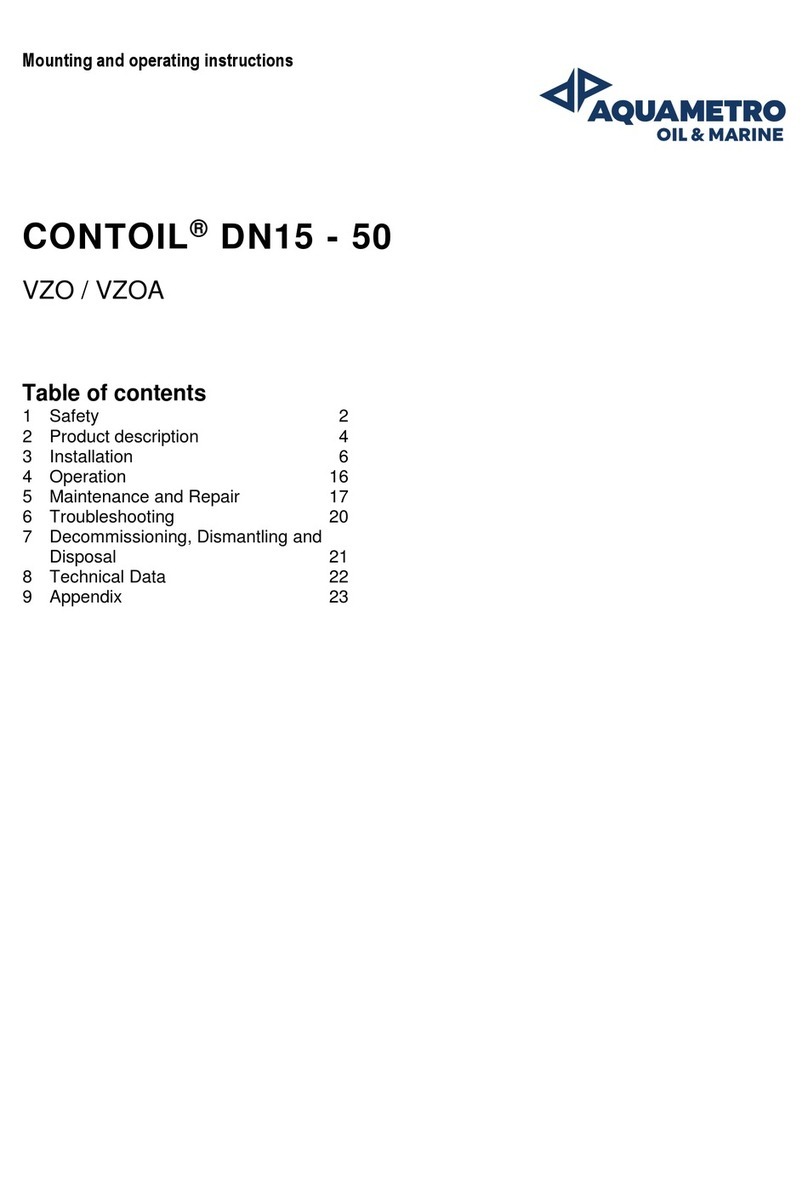

GERÄTEAUFBAU / METER CONFIGURATION / STRUCTURATION DES COMPTEURS ...............3

ZUSÄTZLICHE ANLEITUNGEN /SUPPLEMENTARY INSTRUCTIONS /MANUELS D'INSTRUCTIONS COMPLÉMENTAIRES .......3

MESSKAMMERVERSION /VERSION OF MEASURING CHAMBER /TYPE DE CHAMBRE DE MESURE....................................3

CONTOIL®MESSAUFNEHMER FÜR / FLOW SENSORS FOR / MESUREURS POUR: VZF(A) II /

VZO(A)................................................................................................................................................4

CONTOIL®MAINTENANCE SET .......................................................................................................4

SCHRAUBEN-ANZUGSDREHMOMENTE / SCREW TORQUE / SERRAGE DES VIS......................4

ZÄHLER MIT MESSUMFORMER UND MULTIFUNKTIONSANZEIGE / METER WITH

TRANSDUCER AND MULTIFUNCTIONAL DISPLAY / COMPTEURS AVEC AFFICHAGE

MULTIFONCTIONS ET SORTIES PARAMÉTRABLES VZF II / VZFA II............................................5

VZF(A) II...............................................................................................................................................................5

UMBAU EINES ZÄHLERS ..........................................................................................................................................5

MODIFYING A METER ..............................................................................................................................................5

MODIFICATION D'UN COMPTEUR...............................................................................................................................5

ZÄHLER MIT ROLLENZÄHLWERK / METERS WITH ROLLER REGISTER / COMPTEURS AVEC

TOTALISATEUR À ROULEAUX ........................................................................................................6

VZO MAX.130°C...................................................................................................................................................6

ZÄHLER MIT ROLLENZÄHLWERK / METERS WITH ROLLER REGISTER / COMPTEURS AVEC

TOTALISATEUR À ROULEAUX ........................................................................................................7

VZO MAX.180°C...................................................................................................................................................7

ZÄHLER MIT ROLLENZÄHLWERK / METERS WITH ROLLER REGISTER / COMPTEURS AVEC

TOTALISATEUR À ROULEAUX ........................................................................................................8

VZO… RV MAX.130°C..........................................................................................................................................8

ZÄHLER MIT IMPULSGEBER RV / METERS WITH PULSER RV / COMPTEURS AVEC

EMETTEUR D'IMPULSIONS RV ........................................................................................................9

VZO… RV MAX.180°C..........................................................................................................................................9

ZÄHLER MIT IMPULSGEBER RV / METERS WITH PULSER RV / COMPTEURS AVEC

EMETTEUR D'IMPULSIONS RV ......................................................................................................10

VZOA RV 130 &180°C...................................................................................................................................... 10

VZO/VZOA ZÄHLER MIT IMPULSGEBER IN / METERS WITH PULSER IN / COMPTEURS AVEC

EMETTEUR D'IMPULSIONS IN........................................................................................................11

ABBILDUNGEN / FIGURES / FIGURES...........................................................................................12

FEHLERANALYSE...........................................................................................................................13

REPARATURANLEITUNG UND FEHLERBEHEBUNG.................................................................................................... 14

SICHERHEITSHINWEISE ........................................................................................................................................ 14

REPARATURANLEITUNG MESSAUFNEHMER............................................................................................................ 14

REPARATURANLEITUNG AUFBAUGRUPPEN ............................................................................................................ 14

FAULT ANALYSIS............................................................................................................................15

REPAIR INSTRUCTIONS AND TROUBLE SHOOTING................................................................................................... 16

SAFETY NOTES.................................................................................................................................................... 16

REPAIR INSTRUCTIONS FOR MEASURING SENSORS ................................................................................................ 16

REPAIR INSTRUCTIONS FOR ANCILLARIES.............................................................................................................. 16

DÉPANNAGES.................................................................................................................................17

INSTRUCTIONS POUR RÉPARATIONS ET DÉPANNAGES ............................................................................................ 18

RECOMMANDATIONS EN MATIÈRE DE SÉCURITÉ..................................................................................................... 18

INSTRUCTIONS DE RÉPARATION POUR MESUREURS................................................................................................ 18

INSTRUCTIONS DE RÉPARATION POUR DISPOSITIFS COMPLÉMENTAIRES.................................................................. 19