2 VCS - Viscomaster™

Content

1 Introduction......................................................................................................................................... 3

1.1 Liability Disclaimer ..............................................................................................................................................................................3

1.2 Safety precautions...............................................................................................................................................................................3

1.3 Receiving and Storage Requirements .........................................................................................................................................4

2Application.................................................................................................................................... 4

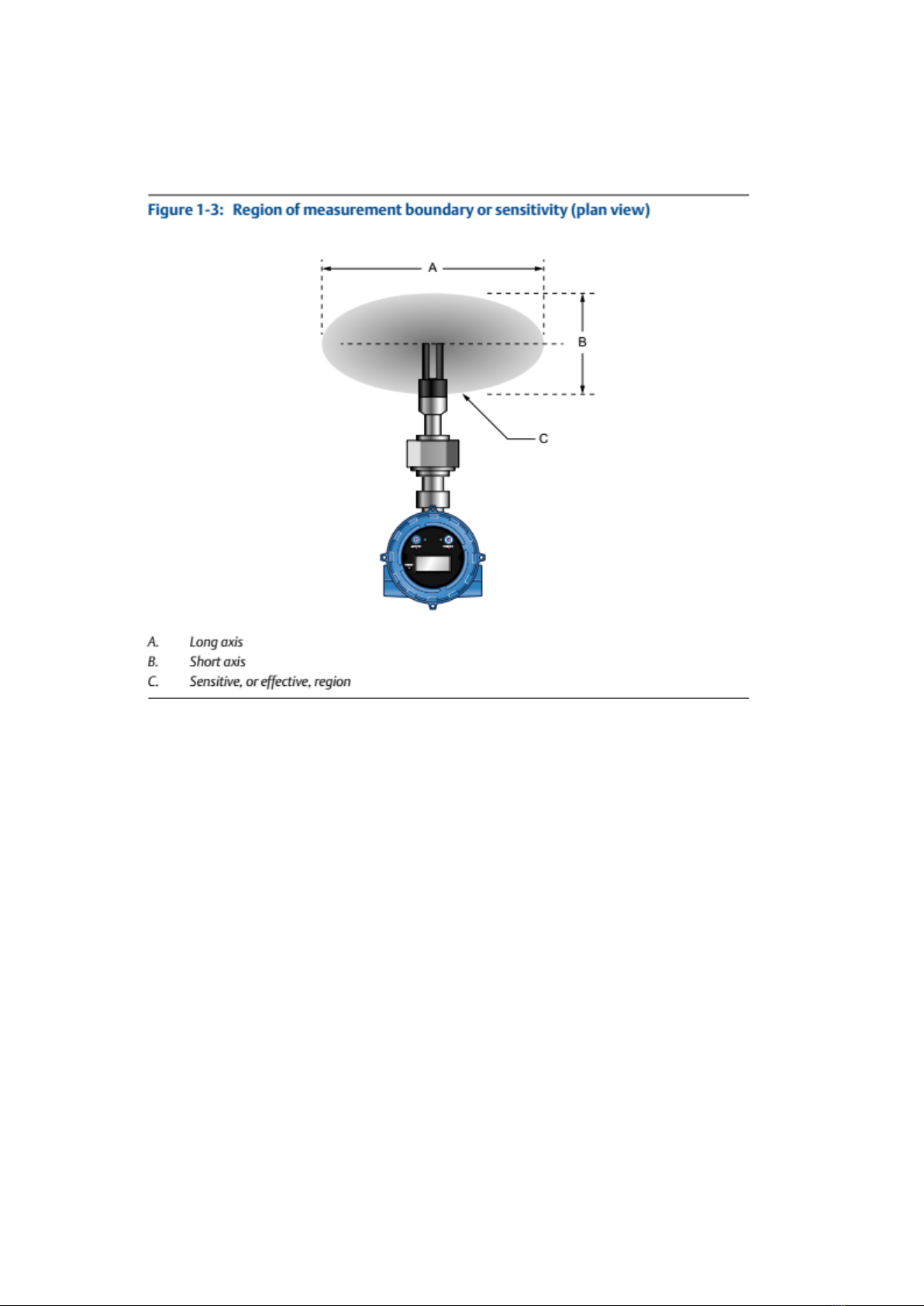

2.1 Description of Viscomaster™ Sensor...........................................................................................................................................4

3Viscosity Sensor installation / implementation ........................................................................ 5

3.1 Planning...................................................................................................................................................................................................5

3.1.1 Installation checklist.....................................................................................................................................................................6

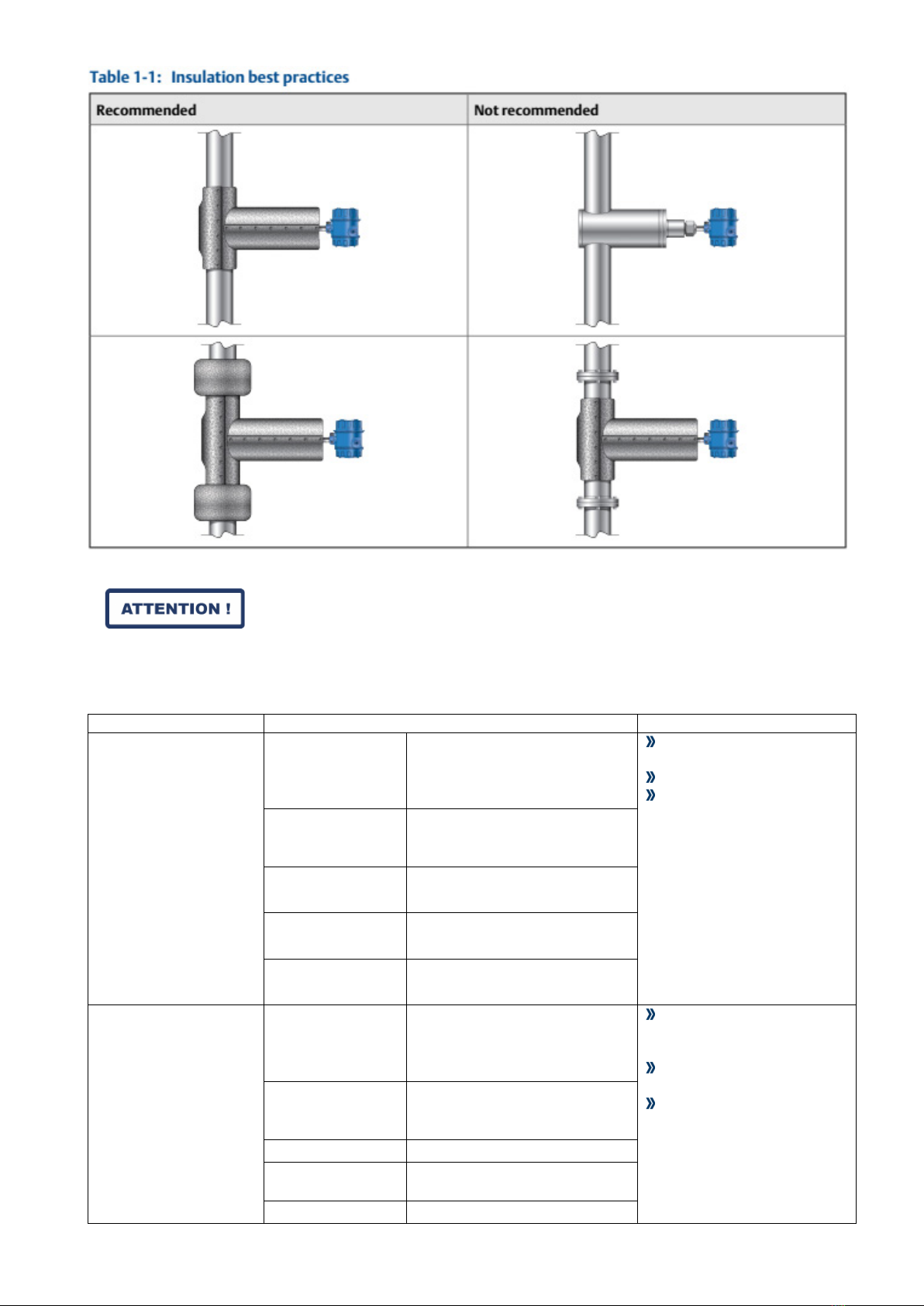

3.1.2 Best practices..................................................................................................................................................................................6

3.1.3 Power requirements.....................................................................................................................................................................6

3.1.4 Other installation considerations............................................................................................................................................7

3.1.5 Perform a pre-installation meter check.............................................................................................................................12

3.2 Mounting ............................................................................................................................................................................................. 12

3.2.1 Prepare the installation............................................................................................................................................................13

3.2.2 Mount the meter........................................................................................................................................................................13

3.2.3 Rotate the electronics on the meter (optional)..............................................................................................................18

3.2.4 Rotate the display on the transmitter (optional)...........................................................................................................18

3.3 Wiring.................................................................................................................................................................................................... 19

3.3.1 Terminals and wiring requirements ....................................................................................................................................19

3.3.2 Wire power and outputs in Signal device and Modbus Environment ..................................................................20

3.3.3 Grounding..................................................................................................................................................................................... 21

4Viscomaster Operation .............................................................................................................. 22

4.1 Putting into Operation ................................................................................................................................................................... 22

4.2 Check meter status .......................................................................................................................................................................... 22

4.3 Configure Modbus communication ..........................................................................................................................................23

5Maintenance and Repair............................................................................................................ 25

5.1 Calibration ...........................................................................................................................................................................................25

5.2 Service maintenance .......................................................................................................................................................................25

5.3 Spare Parts ..........................................................................................................................................................................................27

6Troubleshooting ......................................................................................................................... 28

7Decommissioning, Dismantling and Disposal ......................................................................... 31

7.1 Decommissioning............................................................................................................................................................................. 31

7.2 Dismantling.........................................................................................................................................................................................31

7.3 Return of materials........................................................................................................................................................................... 31

7.4 Disposal................................................................................................................................................................................................32

8Technical Data ............................................................................................................................ 32

8.1 Viscomaster.........................................................................................................................................................................................32

8.2 Dimensional drawings .................................................................................................................................................................... 33

8.3 Electrical Connection diagrams...................................................................................................................................................34

9Appendix ..................................................................................................................................... 40

9.1 Using the transmitter display (Option) ....................................................................................................................................40

9.1.1 Components of the transmitter interface.........................................................................................................................40

9.1.2 Use the optical switches..........................................................................................................................................................40

9.1.3 Access and use the display menu system ........................................................................................................................41

9.2 Display operation ............................................................................................................................................................................. 42

9.2.1 View process variables using the display .........................................................................................................................42

9.2.2 View and acknowledge status alerts ..................................................................................................................................42

9.2.3 You can control the process variables shown on the display and a variety of display behaviors. ............ 45

9.3 Display codes and abbreviations................................................................................................................................................45