2

Thank you to choose an AQUATEC Watermaker for the provisioning of fresh water on your boat.

AQUATEC equipment is made from high-quality components exclusively and has proven its reliability

on long cruising-yachts. We are convinced that our product will serve you for many years without

interferences.

This instruction includes important safety information and instructions for commissioning,

operation and maintenance of the Aquatec Watermaker components. It is essential therefore, that the

responsible specialist refers to it before starting any work on the machinery as well as prior to

commissioning. Furthermore, this instruction must always be available on site.

To ensure total satisfaction, please read this user manual carefully. Warranty will be void if the installation does

not meet this requirement. Disregarding the warnings / instructions in the User Guide and incorrect installation

can lead to serious health damage or possibly the loss of the vessel.

The following symbols and their meaning must be observed throughout the manual. Please follow the

instructions and take appropriate measures.

EXPLANATION OF SYMBOLS

Warning!

Immediate danger that

can lead to serious injury

to persons or damage to

the machine or the loss of

the vessel.

Warning!

Warnings regarding electric

power equipment. Non-

observance of safety

instructions could lead to

danger of life or limb:

Attention!

Indicates an

instruction that

requires

special

attention.

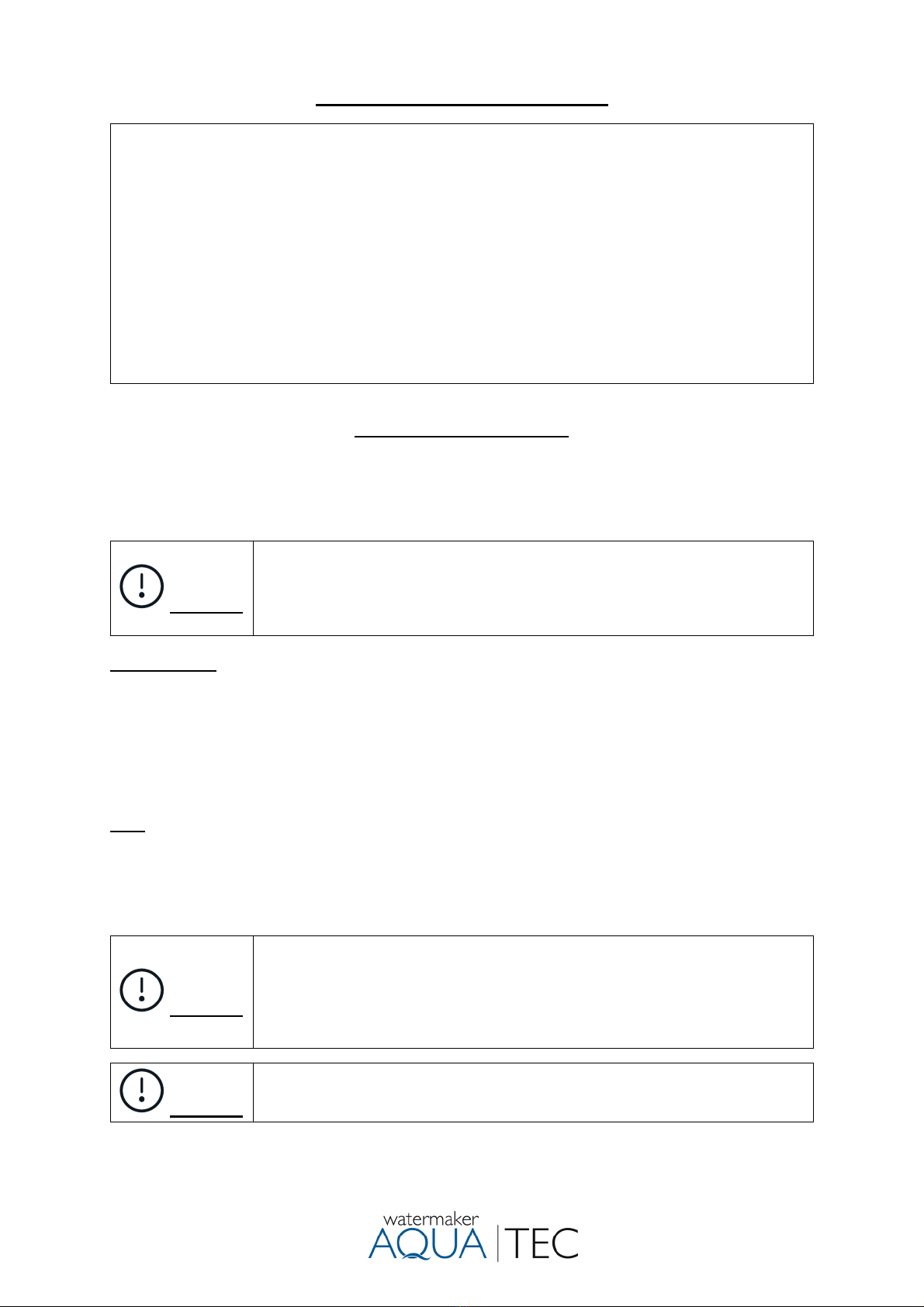

Please note the following information.

Wa

nin

!

Damage to pumps and system parts due to dry running or insufficient water

supply are not covered by warranty.

Wa

nin

!

Aquatec Watermaker are designed for permanent installation on ships.

Operation of the system is only permitted with clean seawater.

Warning!

Never operate your Aquatec Watermaker unsupervised and leave the

operation only to trained persons.

Please note: If there are any leaks, the boat can fill up with water and sink,

thereb

endan

erin

the life of the people on board.

Warning!

The maximum working pressure of 55 bar (800 psi) must not be exceeded.

When exceeding the specified product water quantity (seawater with lower salt

content, brackish water

, the workin

pressure must be reduced.

Warning!

Install the high-pressure pump on a stable substrate

.

Install the high-pressure

pump in a dry area which allows an exchange of air necessary for cooling the

motor-pump unit.

The pumps may not be operated if explosive or flammable Materials are present.

Please note: The motors and pumps develop high temperatures during

operation. Touchin

it can cause burns.

Warning!

The installation of the hoses to the components of the system must be carried

out in compliance with the bending radii without stress and vibration (risk of

breaka

e

.

Attention!

Like any piece of mechanical equipment, the system will require inspection and

service from time to time. For easy access to enable a simple regular monitoring

and proper maintenance do not place the components in inaccessible areas.

It should be easily accessible roundly to make service and inspection work as

comfortable as possible.

Attention!

The already assembled membranes can be stored for approx. 5 months in the

sealed pressure tube, preferably cool, but preferably not above 20 ° ambient

temperature. However, we recommend installing and using the Watermaker as

soon as possible.