The socket is located in the seat box and is attached under the seat.

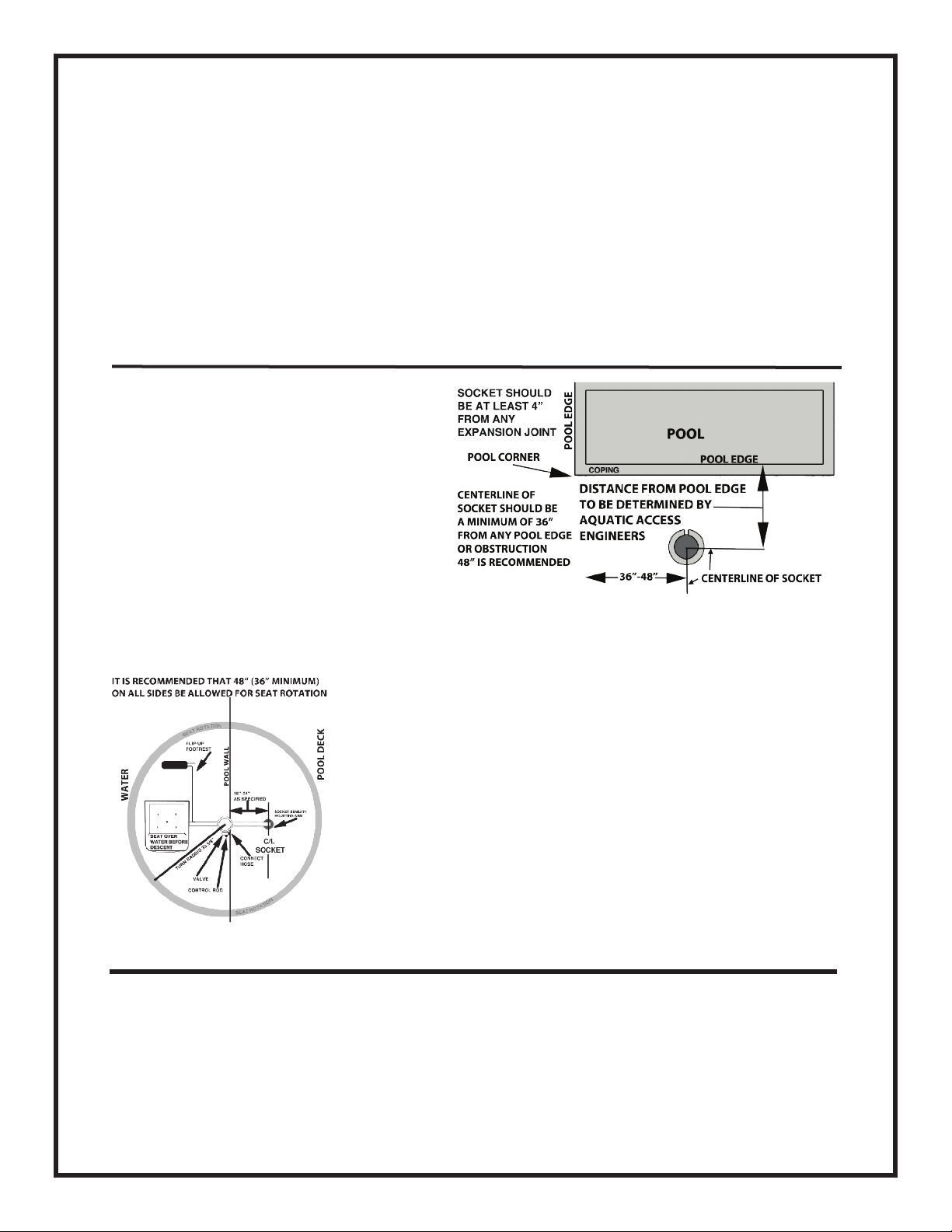

A 5" carbide core drill makes an excellent clean hole in solid concrete. The centerline of the

socket hole should be _____" from the pool wall or ______" from the edge of the deck. Drill

the hole at least 12"deep. Some customers have found it useful to insert a piece of pipe that is at

least 24" long full depth into the socket. Tape the top end of the socket to the pipe to prevent any

liquid cement from entering the top of the socket. This assures a clean socket interior when the

pipe is removed after the cement is hard. Pour a small amount of anchor cement into the bottom

of the hole. After placing the socket into the hole so that its top edge is ush with the surface of

the deck and the notch in the top of the socket is facing the pool, pour the anchor cement around

the socket. A spirit level should be held along the extension pipe to assure that the socket is

vertically plumb while the cement sets (about 15 minutes). Allow the cement to cure overnight

before proceeding.

LIFT ASSEMBLY

1. Insert lift into socket.

2. Attach seat assembly to cylinder assembly with the bolt provided. Adjust seat height by

choice of hole on piston rod frame. Tighten lock nut securely, making sure bolt has penetrated

nylon insert of lock nut. Two bolt threads should be visible past the nylon insert.

3. On the IGAT-180AD, which normally includes a footrest, rst unscrew the T-bolt under the

side of the seat, and then insert the top of the footrest tube into the holder. Slide in to desired

length and turn T-bolt handle clockwise to tighten.

4. If the optional headrest has been ordered, follow the same procedure as footrest to install the

headrest in the headrest bracket on the seat back.

5. Seat belts are installed by sliding the belts through the upper and/or lower slots cut into the

side edges of the seat.

WATER CONNECTIONS

The pool lift is operated by city/household water pressure, with no electricity needed. Our

system is designed for most efcient operation at 60-PSI static pressure or 55 PSI operating

(open ow) pressure to lift 350 lbs. Note that the pressure requirement for a faucet or hose

connection is approximately 10% higher to achieve the rated load.

If your static water pressure measurement is greater than 70 PSI, a reducer must be used between

the water sources and the lift or damage to the lift may result. Purchase a reducer at your local

plumbing supply store. Aquatic Access Inc. is not liable or responsible for damage caused by

excessive water pressure.

2