8

If a desiccant tube is not installed in line with the cable, water may have condensed in

your vent tube causing it to plug. After you are finished installing the desiccant tube

you can test the vent tube by applying a small amount of pressure to the end of the

desiccant tube and seeing if this affects the transmitter reading.

Zero Readings When Pressurized

Continuous zero readings are caused by an open circuit which usually indicates broken

cable, a bad connection, or possibly a damaged transmitter. Check the connector to see

if a wire has become loose, or if the cable has been cut. If neither of these appears to

cause the problem, the transmitter needs factory repair.

Technical Specifications

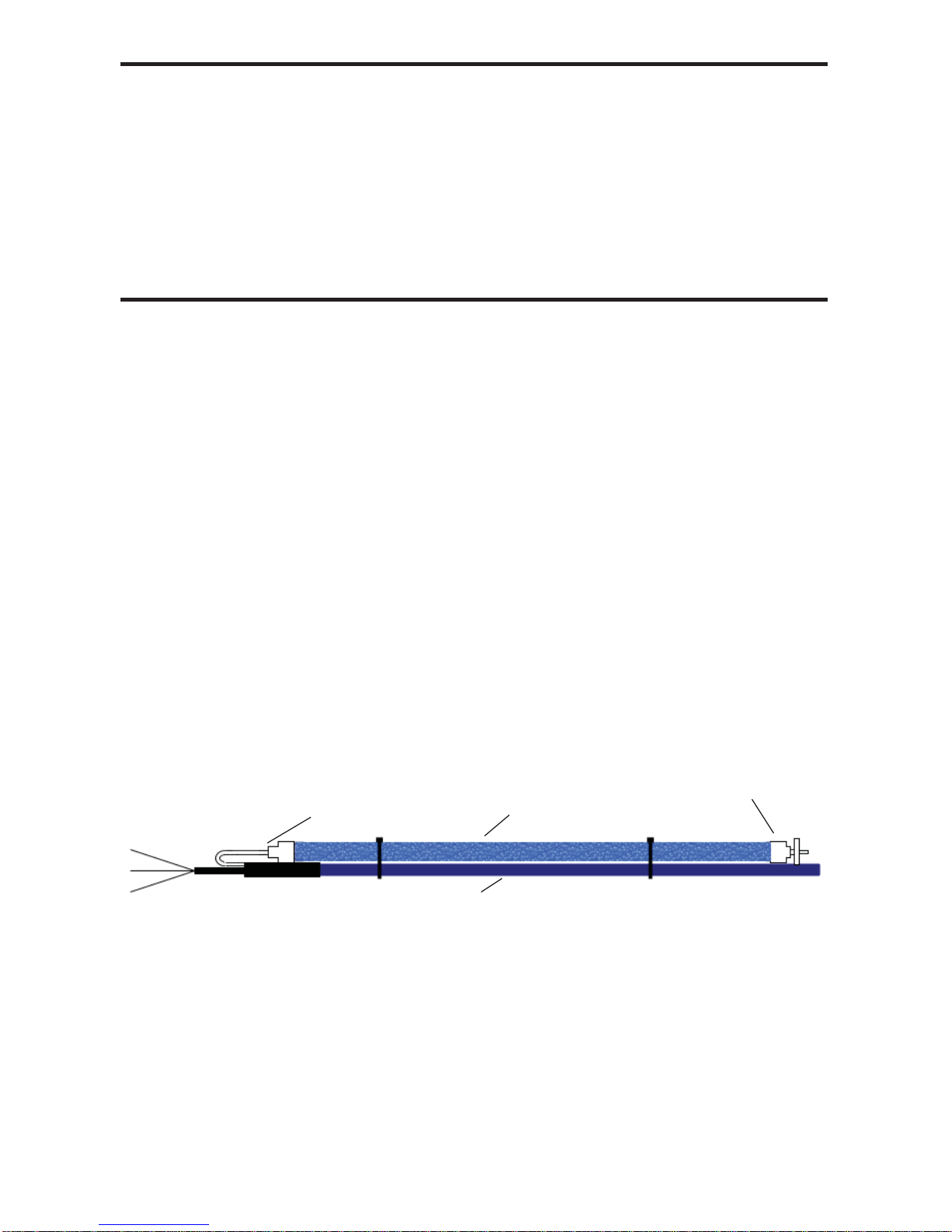

The PS98i submersible pressure transmitter represents the latest in state-of-the-art level

measurement technology. This industry standard two-wire, 4-20 mA device offers

improved noise immunity, thermal performance and transient protection. In addition

to reverse polarity protection, under-current and over-current limitation are featured on

both transmitter channels.

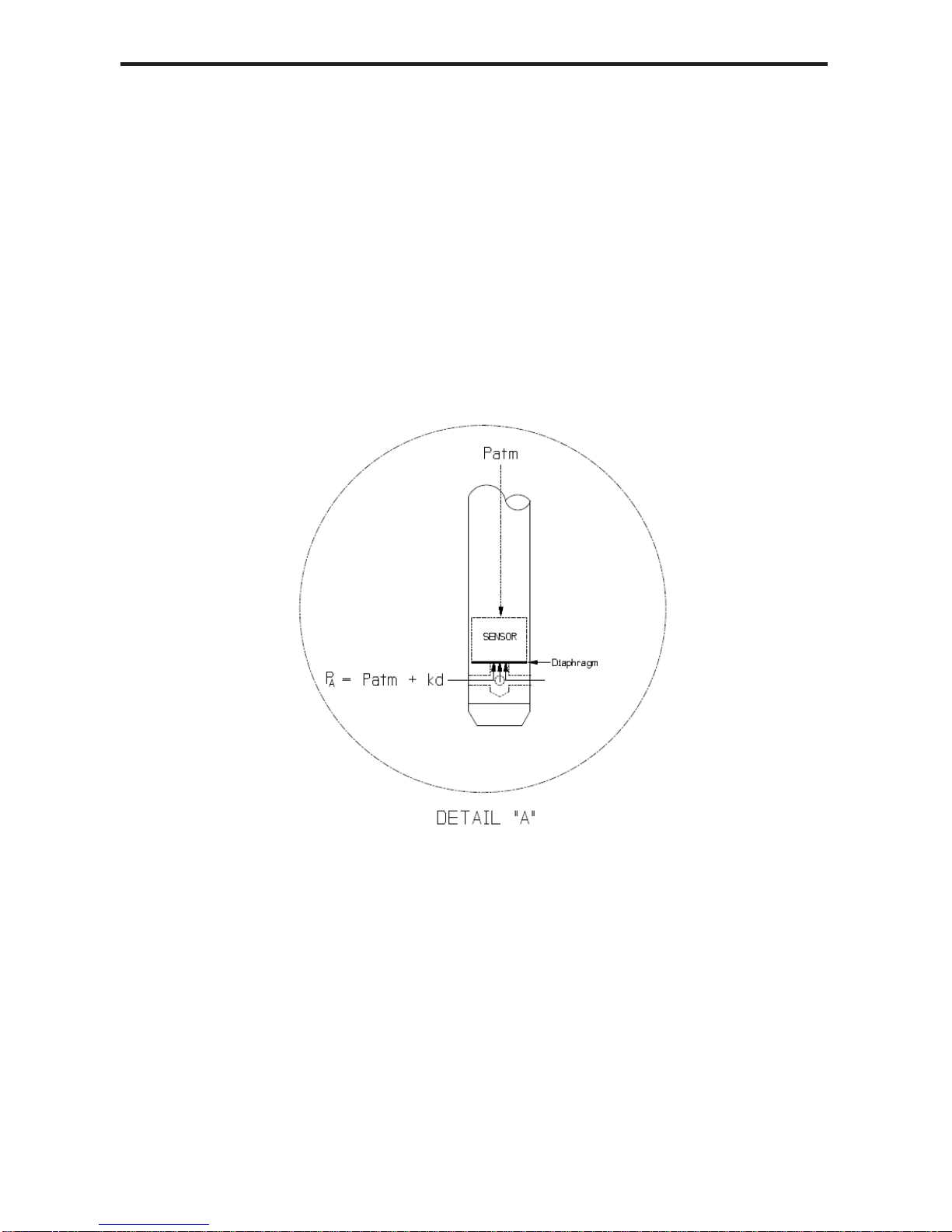

As mentioned above, the PS98i & PS9800 transmitters are current loop devices. This

means that changes in pressure imposed on the stainless steel diaphragm result in

proportional changes in current. The excitation source (DC supply or data logger) sup-

plies the power but the transmitter actually controls how much current flows as long as

the excitation specifications (e.g., voltage level) are met.

For a standard gauge pressure device, there is zero pressure on the diaphragm when

above the surface of the liquid. This zero pressure is converted to a current flow of

4 mA. As the transmitter is lowered into the liquid, the amount of current that flows

increases linearly (with increasing depth) to 20 mA when the maximum rated pressure

(thus depth) is reached. That is, there is a straight line relationship between pressure

(thus depth of submergence) and the amount of current that flows. Adata logger there-

fore can apply power, measure the amount of current that is flowing and convert that to

the depth of submergence using a multiplier and offset (m and b, respectively, for a y =

mx + b straight line) which are preset in the logger by the user.

Compute these m and b values as follows:

m = (Total range of measurement in your units) / 16 / 1000

For example: if you want to measure 0 – 15 psi:

15 / 16 / 1000 = .0009375

b = m * 4000 * (–1)

Using our 0 – 15 psi example above, this would be

.0009375 * 4000 * (–1) = –3.75