ARA PY300DC User manual

SLIDING GATE OPERATOR

USER’S MANUAL

PY300DC

OUTLINE

1. PRODUCTS INTRODUCTION 2

2. IMPORTANT SAFETY PRECAUTIONS 2

3. MAIN TECHNICAL PARAMETERS 2

4. MECHANICAL INSTALLATION 3

5. ADJUSTMENT 5

6. WIRE CONNECTING 6

7. ELECTRICAL AND CONTROL BOARD 7

8. PROGRAMMING PROCESS 8

9. MAINTENANCE 10

10. TROUBLE SHOOTING 11

11. PACKING LIST 11

1. PRODUCTS INTRODUCTION

PLEASE READ THE INSTRUCTIONS CAREFULLY BEFORE

PROCEEDING.

THE OPERATOR CONTAINS EXTRA BATTERY, TRANSFORMER,

CONTROL BOARD AND RADIO CONTROL. IN CASE OF POWER

FAILURE, THE OPERATOR IS POWERED BY A 24V DC, 4.0AH,

EXTRA BATTERY.

INTELLIGENT CHARGING SYSTEM SUPPLIED.

MCU IS SUPPLIED TO CONTROL THE GATE OPERATOR.

KEYPAD/SINGLE BUTTON INTERFACE. PHOTO BEAM SAFETY

BEAM INTERFACE. USER CAN SELECT AUTO-CLOSE FEATURE.

SOFT START & SOFT STOP. MANUAL KEY RELEASE DESIGN FOR

EMERGENCY PURPOSES. GATE OPERATOR HAS AUTO-REVERSE

FUNCTION, AND THE REVERSE POWER CAN CHANGE BY USER.

2. IMPORTANT SAFETY INFORMATION

CAREFULLY READ AND FOLLOW ALL SAFETY PRECAUTION AND

WARNINGS BEFORE ATTEMPTING TO INSTALL AND USE THIS

AUTOMATIC GATE OPERATOR.

MAKE SURE THE POWER SUPPLY (AC220V OR AC110V) OF

OPERATOR IS SUITABLE FOR THE POWER SUPPLY IN YOUR

AREA.

3. MAIN TECHNICAL PARAMETERS

Unit Model

PY300DC

Power Supply

220VAC/110AC

Max gate weight

300Kg

Max gate width

8m

Motor

24VDC 100W

Output torque

Max 8N.m

Work Duty

S2 30min

Limit Switch

Electronical limit

Gate move speed

13m/min

Remote control Range

>

-30m

Extra remote control

20

Frequency

433.92 MHz

Noise

<60

db

Working Temperature

-

20C - +50C

Extra Battery

24V 4.5Ah

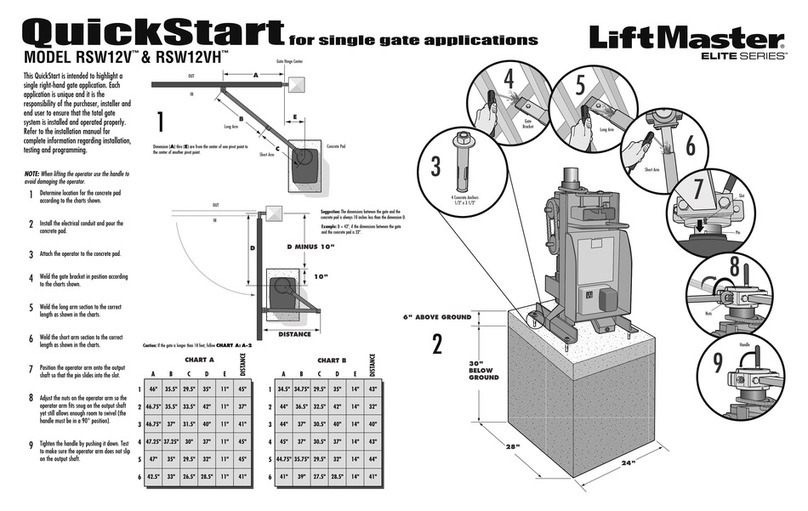

4. MECHANICAL INSTALLATION

THE PY300DC WILL HANDLE GATE WEIGHTING UP TO 300KG AND UP TO

8M IF THE PROPER INSTALLATION PROCEDURES HAVE BEEN FOLLOWED.

THE PY300DC GATE OPERATOR OPERATES BY FORCING A DRIVE RACK BY A

DRIVE GEAR. THE ENTIRE CONFIGURATION IS SHOWN IN THE DIAGRAM

BELOW. THE GATE OPERATOR MUST BE INSTALLED ON THE INSIDE OF THE

GATE.

GATE PREPARATION

BE SURE THE GATE IS PROPERLY INSTALLED AND SLIDES SMOOTHLY BEFORE

INSTALLING THE PY300DC SLIDING GATE OPERATOR. THE GATE MUST BE

PLUMB, LEVEL AND MOVE FREELY.

CONDUIT

IN ORDER TO PROTECT THE WIRES, USE PVC CONDUIT FOR LOW VOLTAGE

POWER CABLE AND CONTROL WIRES. CONDUIT MUST BE PRESET INTO THE

CONCRETE WHEN IT IS POURED. WIRES WITHIN THE CONDUIT SHALL BE

LOCATED OR PROTECTED SO THAT NO DAMAGE CAN RESULT FROM

CONTACT WITH ANY ROUGH OR SHARP PART.

CONCRETE PAD

THE BASE UNIT OF THE GATE OPERATOR REQUIRES A CONCRETE PAD IN

ORDER TO MAINTAIN PROPER STABILITY. THE CONCRETE PAD SHOULD BE

APPROXIMATELY 400MMX250MMX200MM DEEP IN ORDER TO PROVIDE FOR

ADEQUATE WEIGHT AND STRUCTURE TO INSURE PROPER STABLE

INSTALLATION.

ANCHORS (FIG 2)

YOU CAN USE ANCHOR BOLTS, ANCHORS, WASHERS AND NUTS. THESE

ANCHORS MUST BE SET INTO THE CONCRETE WHEN IT IS POURED OR YOU

CAN USE WEDGE ANCHORS TO FASTEN THE OPERATOR.

OPERATOR BASE

AFTER THE CONCRETE HAS HARDENED, MOUNT THE GATE OPERATOR BASE TO

THE CONCRETE PAD. VERIFY THAT THE BASE IS PROPERLY LEVELED. USING

BOLTS AND WASHERS, MOUNT THE GATE OPERATOR TO THE BASE AND

INSERT THE COVER. CHECK THE OPERATOR AND MAKE SURE IT IS LINED UP

WITH THE GATE.

INSTALLATION OF RACK

•FIX THE THREE NUTS (IN THE SAME PACKAGE WITH RACK) ON THE RACK

ELEMENT

•LAY THE FIRST PIECE OF RACK ON THE GEAR AND WELD THE FIRST NUT ON

THE GATE.

•MOVE THE GATE MANUALLY, CHECKING IF THE RACK IS RESTING ON THE

GEAR, AND WELD THE SECOND AND THIRD NUT.

•BRING ANOTHER RACK ELEMENT NEAR TO THE PREVIOUS ONE. MOVE THE

GATE MANUALLY AND WELD THE THREE NUTS AS THE FIRST RACK, THUS

PROCEEDING UNTIL THE GATE IS FULLY COVERED.

•WHEN THE RACK HAS BEEN INSTALLED, ENSURE IT MESHES CORRECTLY

WITH THE GEAR.

•THE SPACE BETWEEN THE RACK AND THE GEAR IS ABOUT 0.5MM.

5. ADJUSTMENT

MANUAL OPERATION

IN CASE OF POWER FAILURE, USE MANUAL RELEASE KEY TO OPEN

OR CLOSE THE GATE MANUALLY, USE THE RELEASE KEY AS FOLLOW:

•FIT THE SUPPLIED KEY IN HOLE

•TURN THE KEY CLOCKWISE TO RELEASE THE CLUTCH

•OPEN AND CLOSE THE GATE MANUALLY

•AFTER POWER RESTORED, USE THE MANUAL RELEASE KEY TO

TIGHT THE CLUTCH BY TURNING THE KEY COUNTERCLOCKWISE

AND RESUME NORMAL OPERATION.

NOTE: THE GATE OPERATOR NEEDED RESET LIMIT AFTER RE-TIGHT

THE CLUTCH, BY TURNING THE KEY COUNTERCLOCKWISE IF THE

POWER FAILURE –AND RELEASE BY HAND.

6. WIRE CONNECTING

CONNECTING THE BATTERY

PLUG THE TERMINAL OF EXTRA BATTERY IN THE CONTROL BOARD.

NOTE: IF YOU NOT USE GATE OPERATOR AND POWER FAILURE, PLEASE PULL

OUT THE EXTRA BATTERY TERMINAL (FIG 7).

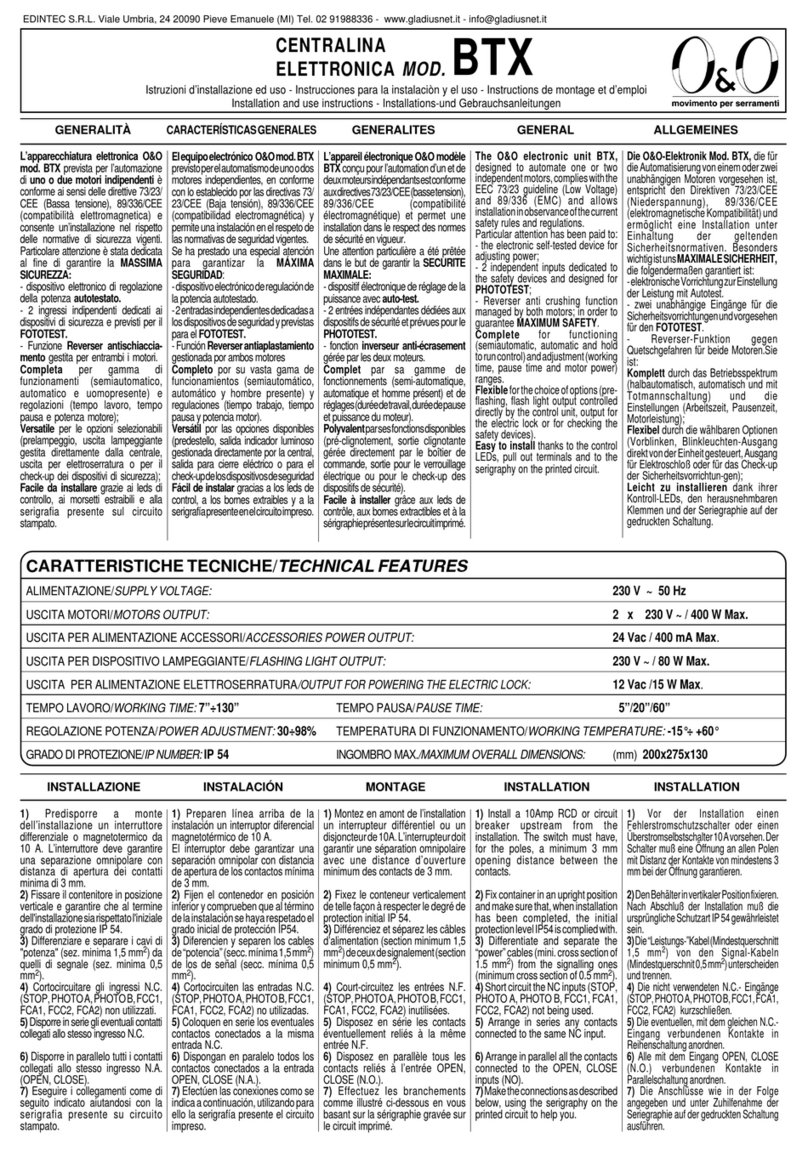

7. ELECTRICAL AND CONTROL BOARD

CONNECTING THE MOTOR

CONNECT THE MOTOR WIRES TO “N-” AND “M+” OF THE TERMINAL

BLOCK T1 (BLACK) AND T2 (RED).

CONNECTING POWER WIRE

MOTOR: GREEN WIRE TO T1 AND RED WIRE TO T2.

J1: TRANSFORMER SECONDARY (AC24V/3.3A)

EXTERNAL PUSH BUTTON (J2,J3,J4)

SINGLE BUTTON (OSC AND COM)

THREE BUTTON (K,G,T AND COM)

PHOTO BEAM (PE AND COM)

OUTPUT DC POWER 24 AND GND

J5: SOLAR PANEL (10W 27V) AND CHARGE BATTERY.

NOTE: PLEASE PUT THROUGH THE J5 BATTERY TERMINAL, IF YOU NEED

THE SLIDING GATES OPERATOR.

8. PROGRAMMING PROCESS

SET BUTTON –MODE SET AND CONFIRM FUNCTION

CODE BUTTON –TRANSMITTER SET AND CLEAR FUNCTION

OPEN BUTTON –OPEN DOOR

CLOSE BUTTON –CLOSE DOOR.

ERASE TRANSMITTER

PRESS AND HOLD CODE UNTIL ‘C’ FLASHES ON THE LED DISPLAY.

THIS INDICATES THAT ALL THE TRANSMITTERS HAVE BEEN ERASED

COMPLETELY.

ADDING EXTRA TRANSMITTER (LEARN)

1. PRESS CODE, A DOT IS INDICATED ON THE LED DISPLAY.

2. PRESS THE TRANSMITTER BUTTON WHICH YOU WANT TO USE (BUTTON 1,2,3,4) THEN

PRESS THE SAME BUTTON AGAIN.

3. THE DOT ON THE LED DISPLAY WILL FLASH THEN TURN OFF.

4. “II” IS INDICATED ON THE LED DISPLAY, THEN THE LEARNING PROCESS IS FINISHED.

UP TO 20 TRANSMITTERS MAY BE USED.

SET OPEN AND CLOSE POSITIONS

1. PRESS AND HOLD SET UNTIL NUMBER 1 IS INDICATED ON THE LED DISPLAY.

2. PRESS AND HOLD OPEN TO SET OPEN POSITION (NOT THE DOOR MUST BE

OPEN –IF NOT –PLEASE CHANGE MOTOR WIRE RED AND GREEN), RELEASE

THE BUTTON UNTIL THE DOOR HAS REACHED THE DESIRED POSITION. (YOU

CAN ALSO PRESS CLOSE TO MOVE THE DOOR CLOSE, OPEN AND CLOSE

CAN BE USED TO FINE ADJUST THE DOOR POSITION).

3. PRESS THE SET TO CONFIRM THE OPEN POSITION, NOW NUMBER 2 IS

INDICATED ON THE LED DISPLAY.

4. PRESS AND HOLD CLOSE TO SET CLOSE POSITION, RELEASE THE BUTTON

UNTIL THE DOOR HAS REACHED THE DESIRED POSITION. (YOU CAN ALSO

PRESS OPEN TO MOVE THE DOOR OPEN, OPEN AND CLOSE CAN BE USED

TO FINE ADJUST THE DOOR POSITION),

5. PRESS THE SET TO CONFIRM THE CLOSE POSITION.

6. THE DOOR WILL DO A COMPLETE OPEN AND CLOSE CYCLE.

AUTOMATIC CLOSE (0-90 SECONDS ADJUSTABLE)

1. PRESS AND HOLD OPEN UNTIL ‘-’ IS INDICATED ON THE LED DISPLAY

2. PRESS OPEN TO INCREASE THE AUTO CLOSE TIME, PRESS CLOSE TO DECREASE TIME.

3. SET TIMER TO ‘0’, THE AUTOMATIC CLOSE FUNCTION WILL DISABLE.

4. PRESS SET TO CONFIRM THE SETTING

5. ADD 10 SECONDS PER NUMBER.

NOTE: AUTOMATIC CLOSE FUNCTION IS AVAILABLE ONLY WHEN THE DOOR IS IN FULLY

OPENED POSITION.

SETTING FOR OBSTRUCTION FORCE

IF THE DOOR MEETS AN OBSTRUCTION DURING CLOSING, IT WILL STOP AND

REVERSE ABOUT 15CM –20CM.

1. PRESS AND HOLD SET. THE LED WILL DISPLAY NUMBERS FROM 1 –4, WHEN

THEN NUMBER 3 APPEARS ON THE LED DISPLAY, RELEASE SET.

2. PRESS OPEN TO INCREASE THE OBSTRUCTION FORCE, THE MAXIMUM FORCE IS

LEVEL 9. PRESS CLOSE TO DECREASE FORCE, TO MINIMUM FORCE IS LEVEL 1.

3. PRESS SET TO CONFIRM.

PHOTO BEAM

CONNECT THE PHOTO BEAM –FOLLOW FIGURE. THE PHOTO BEAM OUTPUT SIGNAL MUST BE N.C.

SIGNAL

PRESS AND HOLD CLOSE UNTIL ‘=‘ IS INDICATED ON THE LED DISPLAY, RELEASE THE CLOSE, ‘11’ WILL

INDICATE ON THE LED DISPLAY.

PRESS OPEN, ‘H’ WILL BE INDICATED ON THE LED DISPLAY. PRESS SET TO CONFIRM.

THEN CONNECT THE PHOTO BEAM - FOLLOW FIGURE.

(NOTE: WHEN NOT USING PHOTO BEAMS, PLEASE CLICK THE ABOVE ACTION AND SET TO ‘11’ STATUS.

9. MAINTENANCE

•CHECK THE DOOR ONCE A MONTH. THE DOOR SHOULD BE CAREFULLY CHECKED FOR BALANCE. THE DOOR MUST BE

IN GOOD WORKING ORDER.

•THE AUTO-REVERSE FUNCTION SHOULD BE REGULARLY INSPECTED, AND ADJUSTED IF NECESSARY. FOR SERVICE,

CALL AN EXPERIENCED TECHNICIAN.

•WE SUGGEST FOR SAFETY REASONS, PHOTOCELLS TO BE USED ON ALL GATES.

•DISCONNECT FROM MAIN SUPPLY BEFORE REPLACING BULB.

•BE SURE TO READ THE ENTIRE MANUAL BEFORE ATTEMPTING TO PERFORM ANY INSTALLATION OR SERVICE TO THE

DOOR OPERATOR.

•OUR COMPANY RESERVES THE RIGHT TO CHANGE THE DESIGN AND SPECIFICATIONS WITHOUT PRIOR

NOTIFICATION.

10. TROUBLESHOOTING

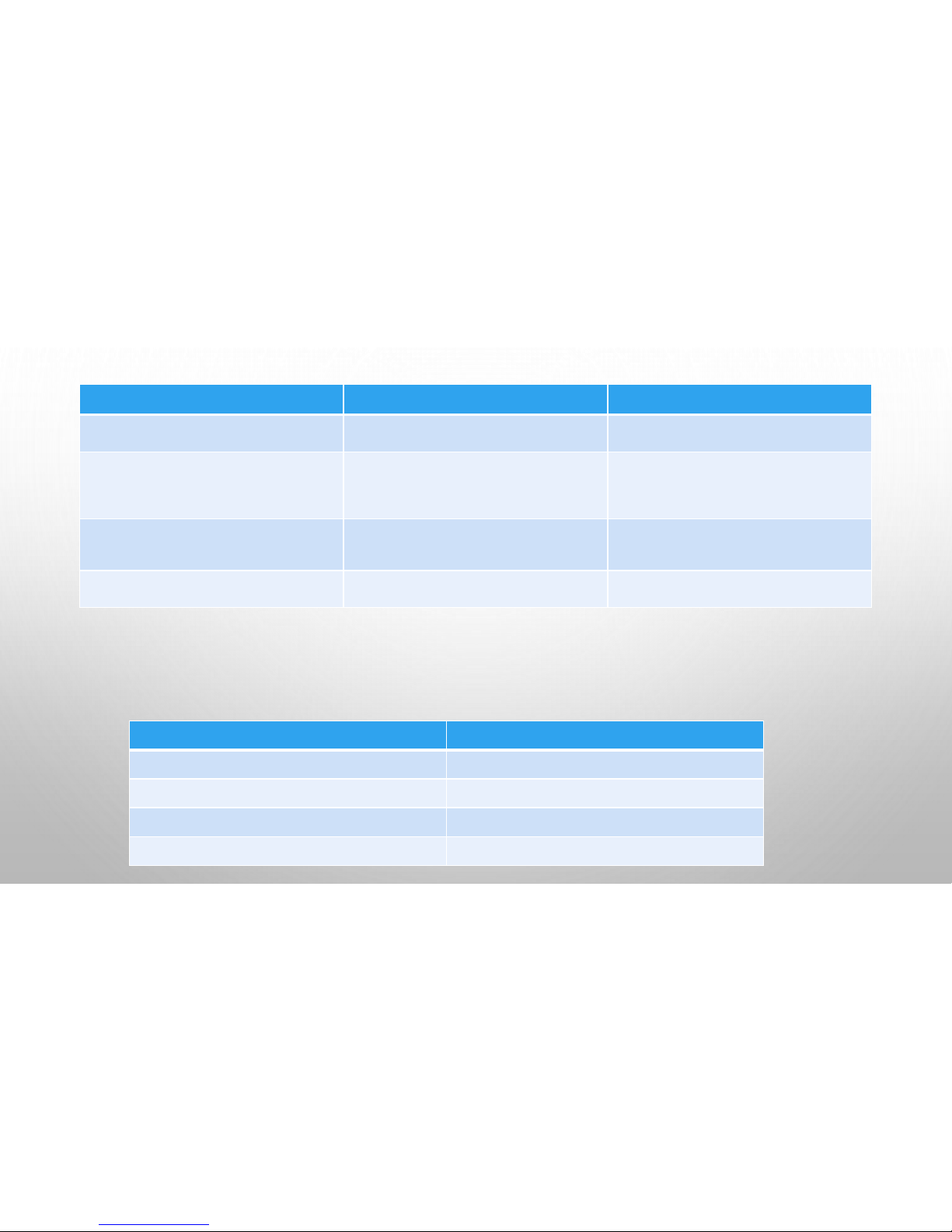

Trouble Possible Causes Solutions

The door fails to open and close. LED display does

not light

1. Power is off

2. Fuse burn

1. Make sure the power is on.

2. Replace fuse

The door can open, fails to close 1. Infrared beam is obstructed.

2. Infrared photocell function is enabled, but the

photocell has not been installed.

1. Remove obstructions

2. Make sure the infrared photocell function is

disabled.

Remote control does not work 1. Battery level may be low.

2. Transmitter

1. Replace the battery inside the transmitter.

2. Re-program the transmitter.

The transmitter operating distance is too short Battery level may be low Replace the battery

11. PACKING LIST

AFTER RECEIVING THE GATE OPERATOR, YOU SHOULD MAKE AN UNPACK INSPECTION, IN WHICH YOU SHOULD CHECK WHETHER THE PRODUCT WAS DAMAGED.

IF YOU HAVE ANY PROBLEM, YOU SHOULD CONTACT OUR DEALER.

YOU SHOULD FIND THE FOLLOWING ITEMS IN OUR STANDARD PACKING:

Item

Quantity

Py300dc sliding gate operator

1

Hand transmitter

2

Release key

1

User’s manual

1

Table of contents

Other ARA Gate Opener manuals