Edition du 29/03/12 2/16 U508113-e Révision 4

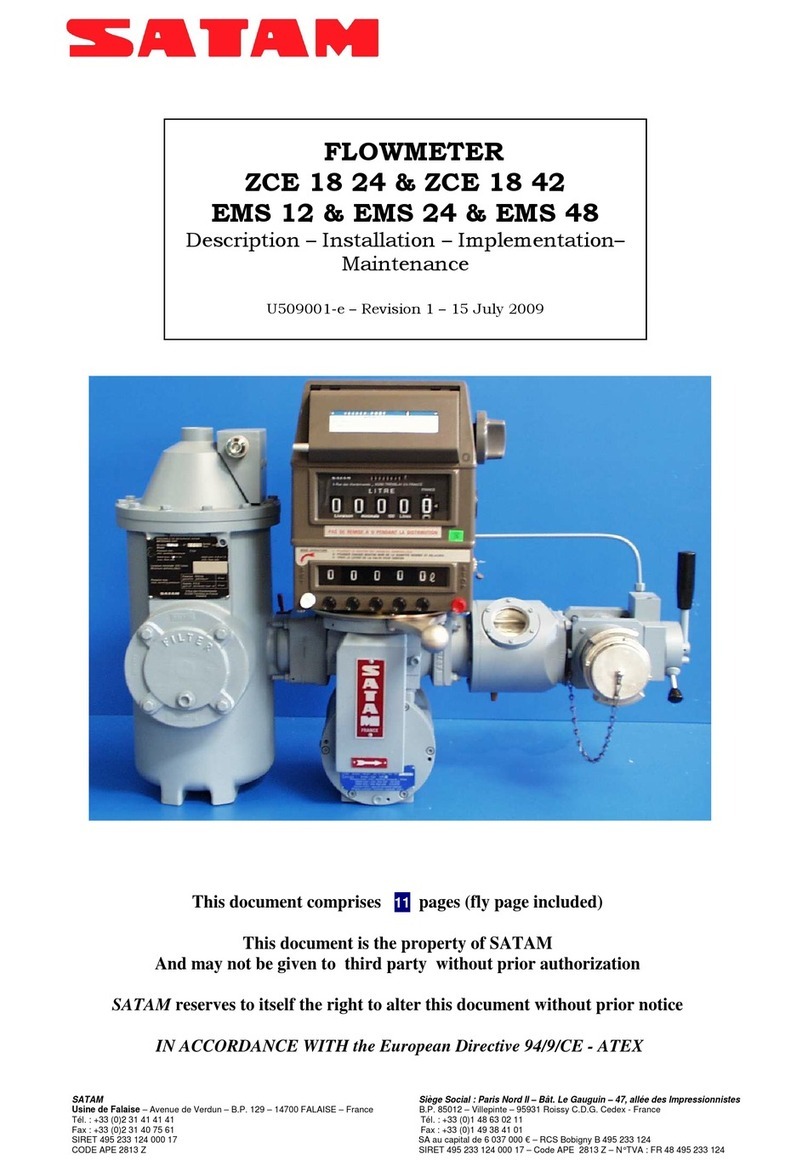

MEASURING CHAMBERS – ZC 17-24 and ZC 17-48 METERS

SUMMARY

1.

GENERAL .....................................................................................................................................................3

2.

RECEPTION..................................................................................................................................................3

3.

OPERATING PRINCIPLE..........................................................................................................................3

4.

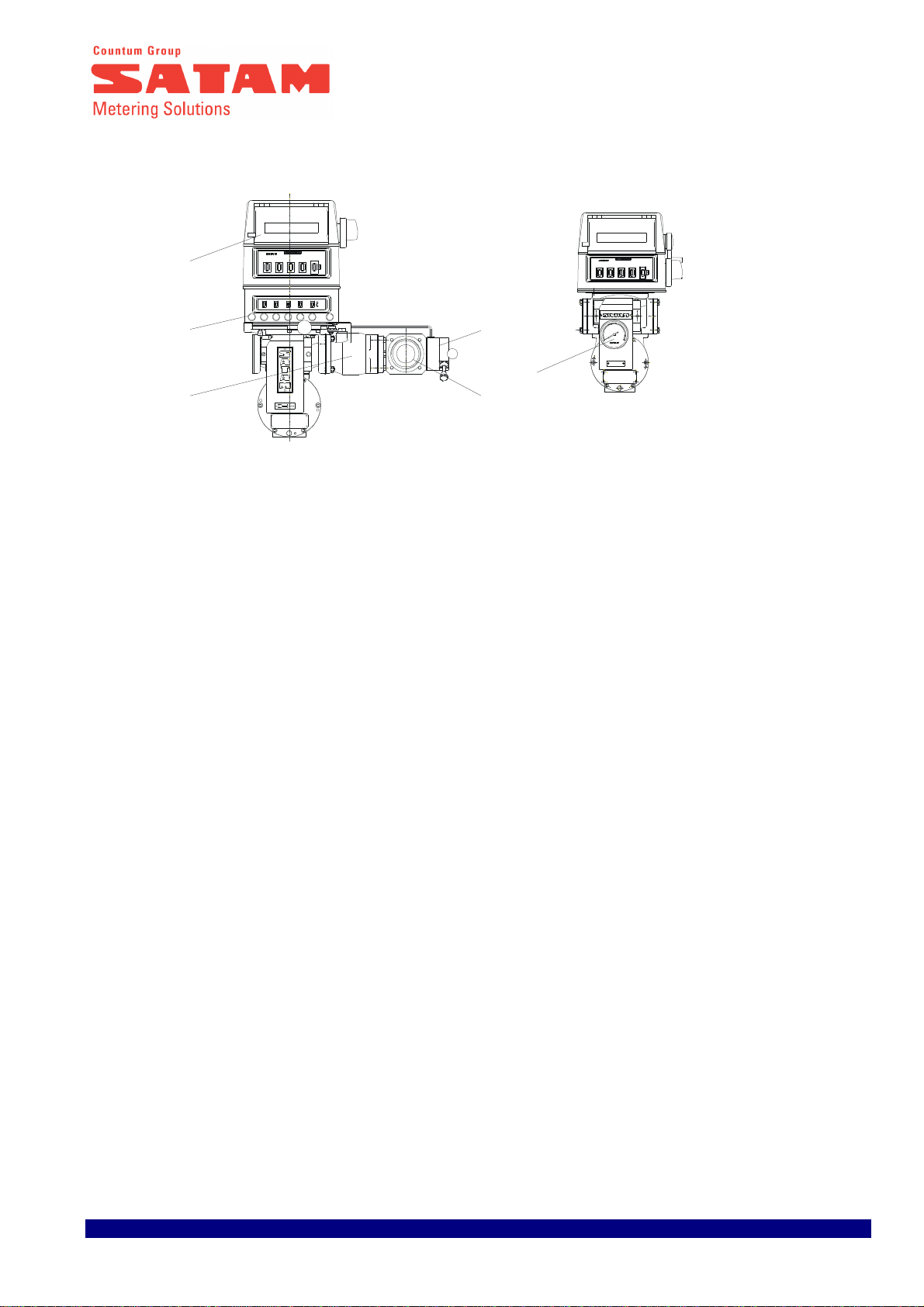

COMPONENTS.............................................................................................................................................4

5.

DESCRIPTION..............................................................................................................................................6

5.1.

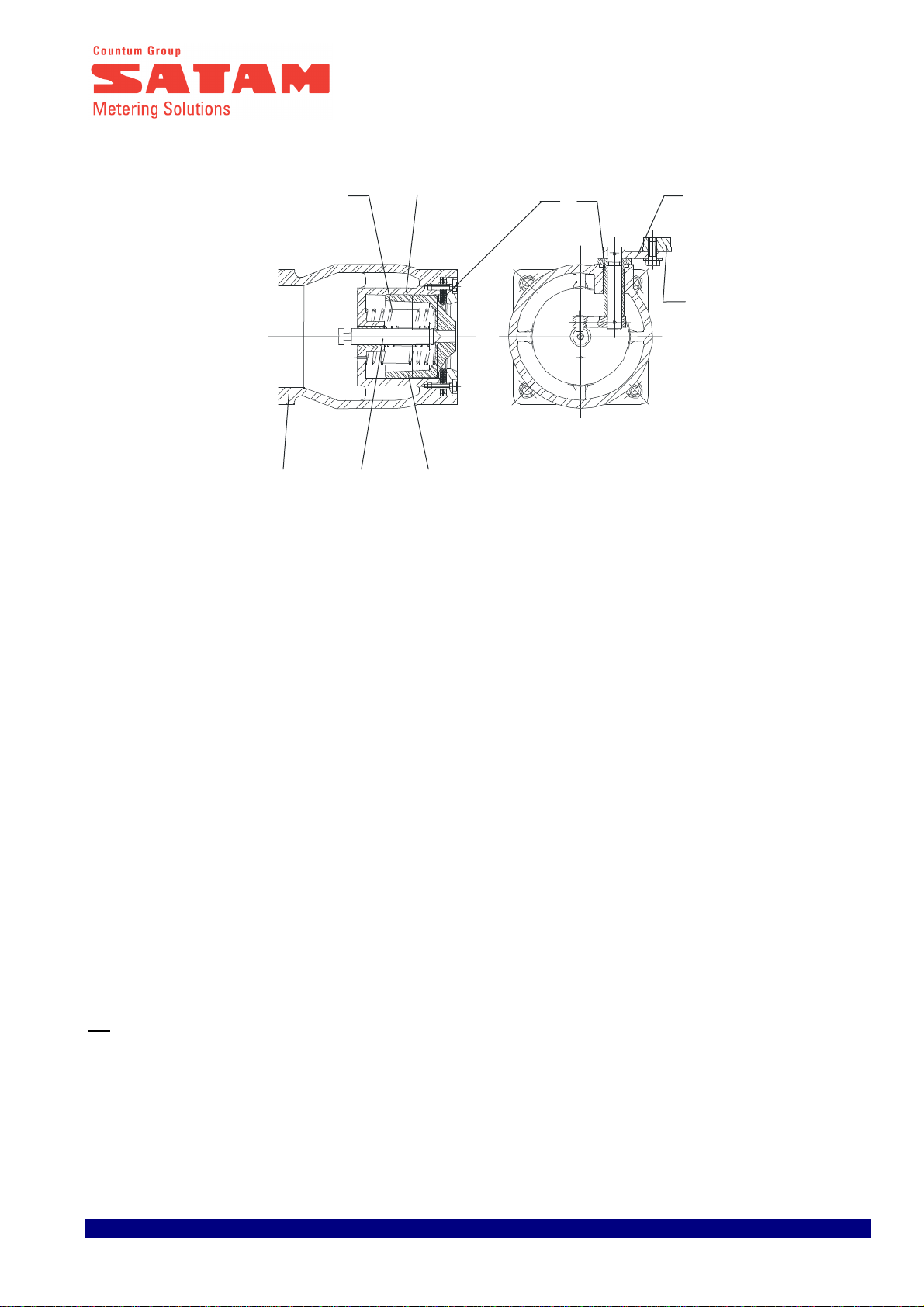

Blade-type positive displacement measuring chamber............................................................................6

5.2.

A manifold................................................................................................................................................7

5.3.

A transmission system..............................................................................................................................8

5.4.

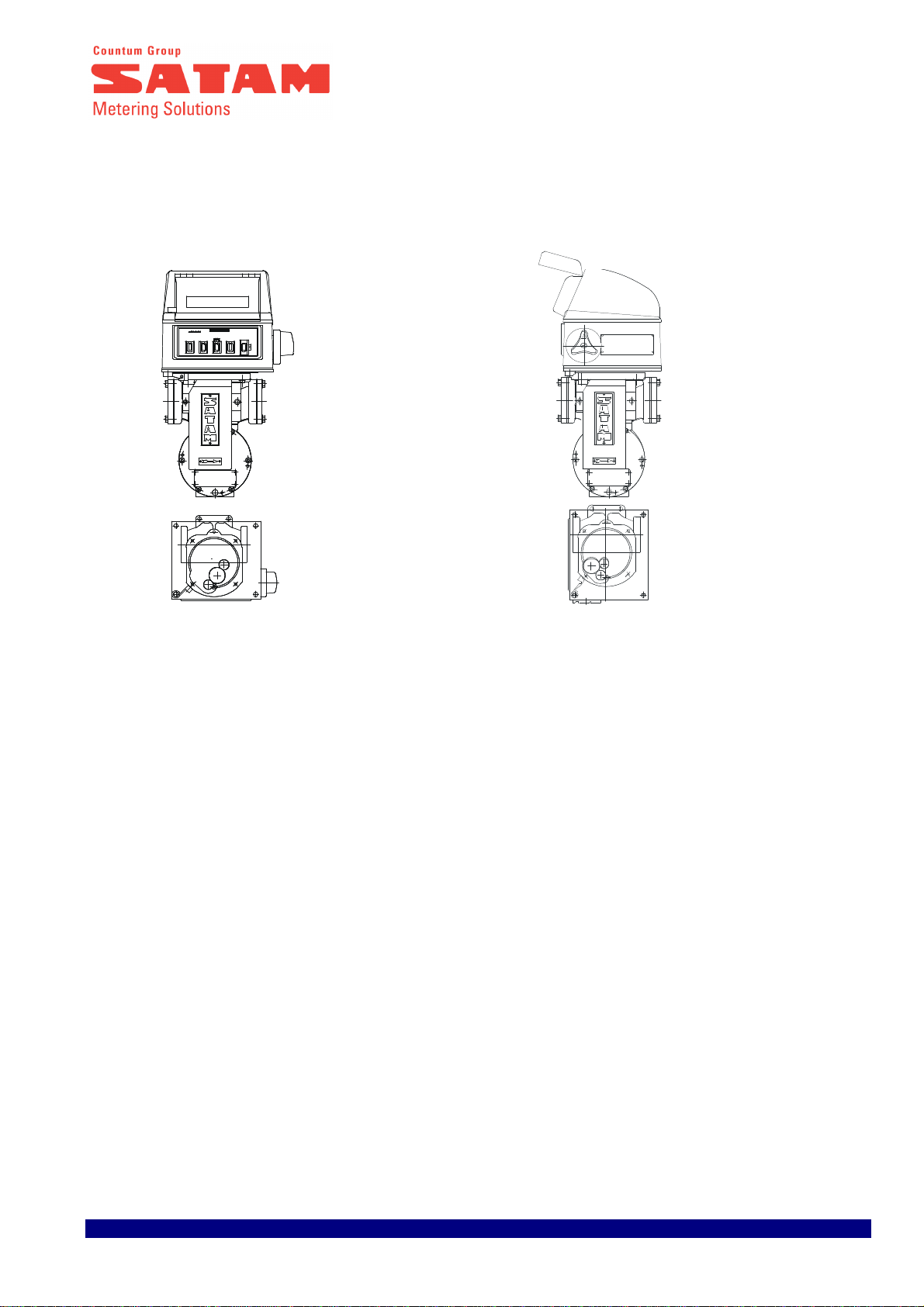

AB 35 Calibrating mechanism.................................................................................................................9

5.5.

Preset with XAD 39 mechanical Preset valve........................................................................................10

5.6.

Preset with XAD 54 pneumatic Preset valve..........................................................................................10

5.7.

Three way valve.....................................................................................................................................10

6.

INSTALLATION.........................................................................................................................................11

7.

OPERATION...............................................................................................................................................11

7.1.

Preset Operation....................................................................................................................................11

7.2.

Checking low flow initiation..................................................................................................................11

7.3.

3 ways valve operation ..........................................................................................................................12

8.

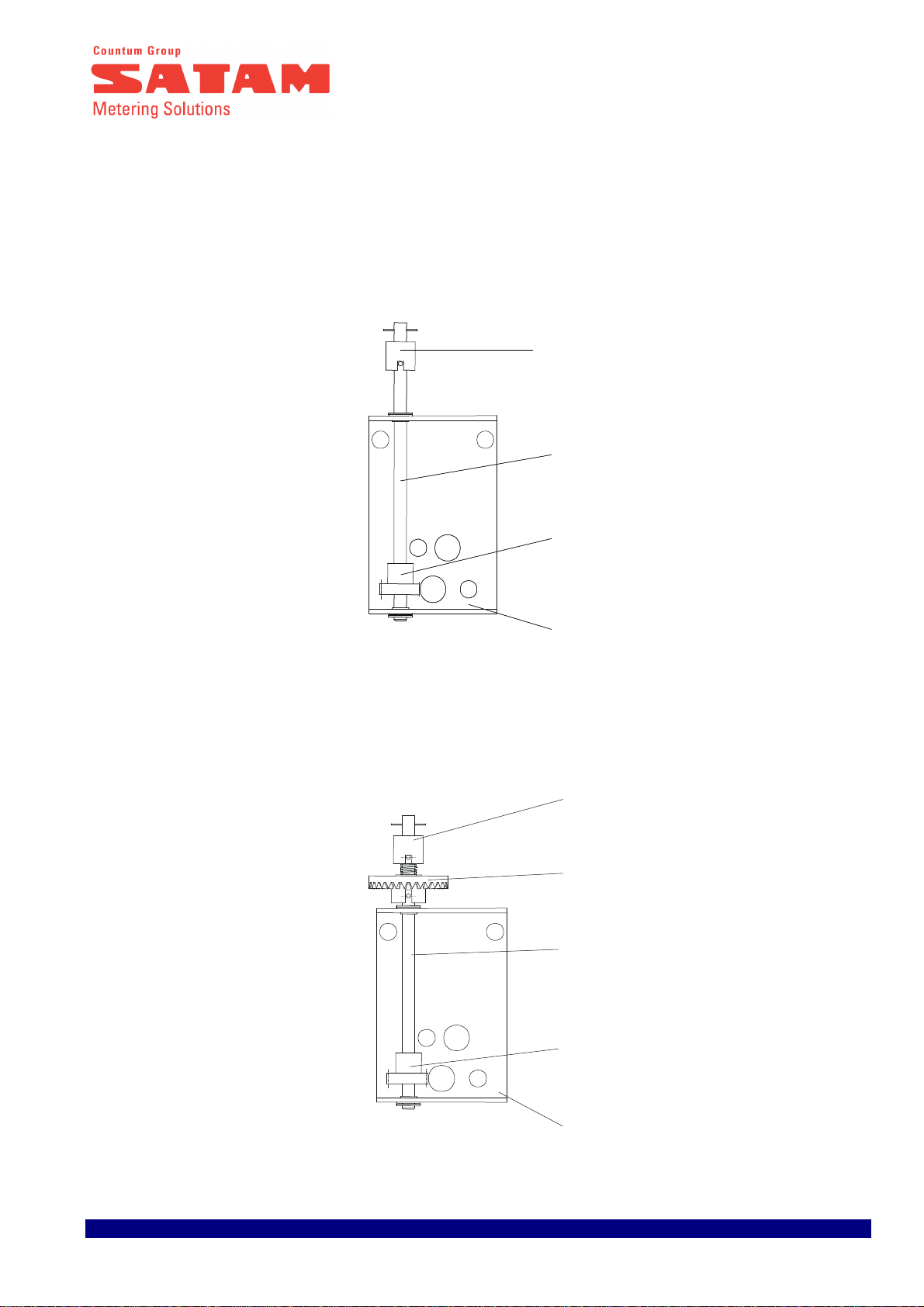

METROLOGICAL INSPECTION MEASURING CHAMBER............................................................13

8.1.

General..................................................................................................................................................13

8.2.

Adjustment Procedure for mechanical meter head................................................................................13

9.

PERIODIC SERVICING............................................................................................................................15

9.1.

General..................................................................................................................................................15

9.2.

Monthly Periodic Inspections................................................................................................................15

9.2.1.

Strainer Baskets .............................................................................................................................15

9.2.2.

MA 21 Measuring Chamber ..........................................................................................................15

9.2.3.

Ticket Printer .................................................................................................................................15

9.3.

Yearly Inspection ...................................................................................................................................15

9.3.1.

MA 21 Measuring Chamber ..........................................................................................................15

9.4.

Meter Head............................................................................................................................................16

9.5.

REMARK VERY IMPORTANT ..............................................................................................................16