ARCA 827S.E Series User manual

Operating manual

Signal box with inductive limit value transmitters for

linear and rotary actuators

Series 827S.E/X

09.2019 / 1.0

Original instructions

© ARCA Regler GmbH. All rights reserved.

Cover picture background: Freepik.com

Table of contents

1 General data...........................................................................................................................5

1.1 Validity of the manual ..............................................................................................................5

1.2 Contact details.........................................................................................................................5

1.3 Other applicable documents....................................................................................................5

1.4 Place of storage of the manual................................................................................................5

1.5 ARCA ONSITE ........................................................................................................................5

2 Safety......................................................................................................................................7

2.1 Introduction..............................................................................................................................7

2.2 General safety information ......................................................................................................7

2.3 Explanation of symbols and notices ........................................................................................7

2.4 Warning symbols on the device ..............................................................................................8

2.5 Intended use............................................................................................................................8

2.6 Improper modifications to the device.......................................................................................9

2.7 Qualified Personnel .................................................................................................................9

2.8 Liability disclaimer ...................................................................................................................9

2.9 Laws and regulations ..............................................................................................................9

2.10 Conformity to European directives ........................................................................................ 10

2.11 Use in potentially explosive areas .........................................................................................10

3 Transport, storage and packaging .................................................................................... 12

3.1 Transport ...............................................................................................................................12

3.2 Storage..................................................................................................................................12

3.3 Packaging..............................................................................................................................12

4 Type plate.............................................................................................................................13

5 Type key ...............................................................................................................................14

6 Description...........................................................................................................................15

6.1 Function.................................................................................................................................15

6.2 Construction ..........................................................................................................................15

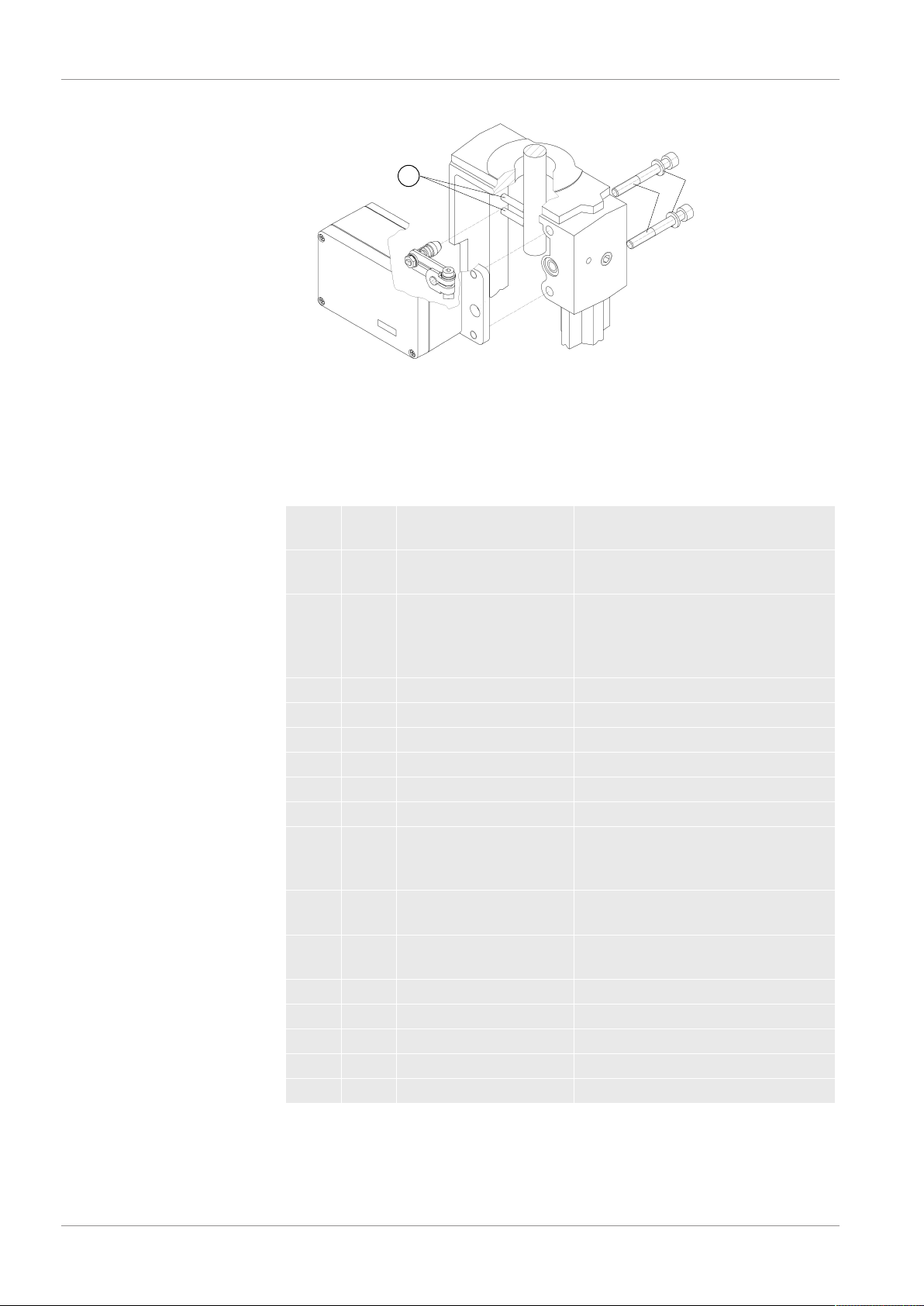

6.3 Device Components ..............................................................................................................16

6.3.1 Electrical Connections...........................................................................................................17

7 Assembly .............................................................................................................................18

7.1 Safety instructions for assembly............................................................................................18

7.2 Mounting a linear actuator.....................................................................................................18

7.2.1 Mounting with mounting kit for "Integrated Fitting Linear Actuator"....................................... 18

7.2.2 Mounting with mounting kit "Linear actuator IEC 60534" ...................................................... 20

7.3 Mounting with mounting kit "Rotary actuator VDI/VDE 3845" ............................................... 23

7.4 Use of the signal box in a humid environment ...................................................................... 26

8 Electrical connection ..........................................................................................................28

8.1 Electrical connection standard ..............................................................................................30

8.2 Electrical connection ignition protection class Ex ia IIC ........................................................ 31

ARCA Regler GmbH Table of contents

Series 827S.E/X 3 / 4209.2019 / 1.0

8.3 Electrical connection, 3-wire, direct switching ....................................................................... 32

9 Commissioning ...................................................................................................................34

9.1 Commissioning......................................................................................................................34

10 Service and maintenance ...................................................................................................36

11 Technical Data .....................................................................................................................38

12 Disposal and recycling .......................................................................................................40

Table of contents ARCA Regler GmbH

4 / 42 Series 827S.E/X09.2019 / 1.0

ARCA Regler GmbH 1 General data

Series 827S.E/X 5 / 4209.2019 / 1.0

1 General data

This operating manual contains instructions that enable the product to

be safely and properly installed, put into operation and maintained.

The target group for this operating manual is exclusively specially

trained and authorised technical personnel.

Please contact the manufacturer if you encounter problems that cannot

be solved with the aid of this operating manual.

The product is subject to technical changes at any time.

1.1 Validity of the manual

This operating manual applies to the product in the version described in

the device pass.

1.2 Contact details

Further information about the product can be obtained from:

Manufacturer's address ARCA Regler GmbH

Kempener Str. 18

D-47918 Tönisvorst

Tel.: +49 (0) 2156-7709-0

Fax: +49 (0) 2156-7709-55

E-mail: [email protected]

www.arca-valve.com

1.3 Other applicable documents

The product can be delivered as part of an actuator and equipped with

additional components that are described in their own operating manu-

als. The instructions as well as the warning and safety information con-

tained therein must also be observed.

Furthermore, the following documents apply in addition to this operating

manual.

▪ Device pass

▪ Installation drawing

1.4 Place of storage of the manual

The operating manual and all other applicable documents are part of the

product.They must be kept in the immediate vicinity of the product and

must be accessible to the personnel at all times.

1.5 ARCA ONSITE

If the product was supplied as part of a complete control valve, the oper-

ating documentation can be downloaded from our ARCA ONSITE portal

with the help of the control valve's serial number.

Two options are available here:

1. Scan the QR code¹, which can be found on the control valve. Further

entries are not required.

1 General data ARCA Regler GmbH

6 / 42 Series 827S.E/X09.2019 / 1.0

2. Visit the website https://onsite.arca-valve.com/search and enter

the ARCA order no. and ARCA serial no. of the control valve. The or-

der no. and serial no. of the control valve can be found on the device

pass and on our order confirmation.

Entry example

Illustration1: ARCA ONSITE

¹ QR Code is a registered trademark of DENSO WAVE INCORPOR-

ATED

ARCA Regler GmbH 2 Safety

Series 827S.E/X 7 / 4209.2019 / 1.0

2 Safety

2.1 Introduction

This manual contains all the information you need for the connection and

commissioning of the device.

It is addressed to people who mechanically mount, electrically connect,

parameterise and commission the device, as well as service and main-

tenance technicians.

This manual applies to devices in both non-intrinsically and intrinsically

safe versions.

We expressly state that the contents of this operating manual do not

form part of or modify a former or existing agreement, assurance or legal

relationship. All obligations are specified in the particular purchase con-

tract which also contains all the applicable warranty regulations. These

contractual warranty conditions are neither extended nor restricted by

any statements in this document.

The contents reflect the technical state at the time of printing.

We reserve the right to make technical changes in the course of further

development.

WARNING

Use of a damaged or incomplete device

Risk of explosion!

► Do not use damaged or incomplete devices.

2.2 General safety information

Requirement for safe use

This equipment has been supplied from the factory in a totally safe con-

dition. To maintain this condition and to ensure safe operation of the

device, follow these instructions and observe all safety-relevant informa-

tion.

Pay attention to the notices and symbols on the device. Do not remove

any notices or symbols from the device. Keep the notices and symbols

in a fully legible condition at all times.

2.3 Explanation of symbols and notices

This documentation contains notes that you must observe for your own

personal safety and for the avoidance of damage to property. Notes con-

cerning personal safety are highlighted by a warning triangle; notes con-

cerning only damage to property are not marked by a warning triangle.

Depending on the danger level, the warning notes are shown in decreas-

ing order of severity as follows:

DANGER

means that death or serious injuries will occur if the corresponding

preventive measures are not taken.

2 Safety ARCA Regler GmbH

8 / 42 Series 827S.E/X09.2019 / 1.0

WARNING

means that death or serious injuries can occur if the corresponding

preventive measures are not taken.

CAUTION

with a warning triangle means that slight injury and/or damage to

property can occur if the corresponding preventive measures are

not taken.

NOTICE

indicates an important item of information about the product itself

or how the product should be handled, to which special attention

should be paid.

CAUTION

without a warning triangle means that damage to property can occur if

the corresponding preventive measures are not taken.

ATTENTION

indicates that an undesirable event or condition can occur if the corres-

ponding instructions are not observed.

If several danger levels occur, the warning note for the respectively

highest level will always be used. If a warning note with a warning tri-

angle warns against personal injury, a warning against damage to prop-

erty may be included in the same warning note.

2.4 Warning symbols on the device

Symbol Explanation of the warning symbols on the device

Observe the operating manual

Protect the device against shocks (otherwise the protection

class is not guaranteed)

2.5 Intended use

Observe the following:

WARNING

ARCA signal boxes may be used only for the applications foreseen

in the associated technical documentation. Proper transport, stor-

age, erection, assembly, installation, commissioning, operation and

maintenance are required for trouble-free and safe operation. The

permissible environmental conditions must be maintained. Notices

in the associated documentation must be observed.

ARCA Regler GmbH 2 Safety

Series 827S.E/X 9 / 4209.2019 / 1.0

2.6 Improper modifications to the device

WARNING

Modification to the device

Modifications and repairs to the device, in particular in potentially explos-

ive areas, can be dangerous for personnel, the plant and the environ-

ment!

► Modify or repair the device only as described in the instructions for

the device. The manufacturer's warranty and the product approvals

are rendered null and void if this is ignored.

2.7 Qualified Personnel

The device may be set up and operated only in conjunction with this

documentation. Startup and operation may be performed only by quali-

fied personnel. Qualified personnel within the meaning of the safety in-

structions in this documentation are persons who are authorised to com-

mission, earth and mark devices, systems and circuits according to the

safety standards.

Qualified persons are those who are familiar with the erection, assembly,

startup and operation of the product. These persons possess the follow-

ing qualifications:

▪ They are authorised and have been trained or instructed to operate

and maintain devices and systems in accordance with the safety

standards for electrical circuits, high pressures and aggressive and/

or hazardous media.

▪ In the case of devices with explosion protection: they are authorised

and have been trained or instructed to carry out work on electrical

circuits for plants that are at risk from explosions.

▪ They have been trained or instructed in the care and use of appropri-

ate safety equipment in accordance with safety standards.

2.8 Liability disclaimer

We have checked the contents of this manual for correspondence to the

hardware and software described. Nevertheless, deviations cannot be

ruled out; therefore we cannot give any guarantee for full correspond-

ence. The details are checked regularly and any necessary corrections

will be included in subsequent editions.

2.9 Laws and regulations

The test certificates, regulations and laws applicable to your country

must be observed for the connection, assembly and operation.

These are, for example:

▪ IEC 60079-14 (international)

▪ EN 60079-14 (EC)

▪ Operational safety ordinance

2 Safety ARCA Regler GmbH

10 / 42 Series 827S.E/X09.2019 / 1.0

2.10 Conformity to European directives

The CE mark on the device indicates its conformity to the following

European directives:

2014/30/EU

EMC

Directive of the European Parliament and of the

Council on the harmonisation of the Laws of the

Member States relating to electromagnetic com-

patibility.

2014/34/EU

ATEX

Directive of the European Parliament and of the

Council on the harmonisation of the Laws of the

Member States relating to equipment and protec-

tion systems intended for use in potentially ex-

plosive atmospheres.

2014/35/EU

LVD

Directive of the European Parliament and of the

Council on the harmonisation of the Laws of the

Member States relating to the making available of

electrical equipment designed for the use within

certain voltage limits.

The applied standards can be found in the EU Declaration of Conformity

for the device.

2.11 Use in potentially explosive areas

WARNING

Unsuitable device for potentially explosive areas

Risk of explosion!

► Use only devices that are approved for use in Ex-zones and are

marked accordingly.

► Make sure that the device is suitable for the area of use.

WARNING

Loss of safety of the device in the ignition protection class Intrinsic

Safety "Ex i"

If the device has already been operated on non-intrinsically safe circuits

or with a higher operating voltage, the safety of the device for use in po-

tentially explosive areas is no longer guaranteed. There is a danger of

explosion!

► Connect the device in the ignition protection class Intrinsic Safety ex-

clusively to an intrinsically safe electrical circuit.

► Observe the electrical data in the certificate.

ARCA Regler GmbH 2 Safety

Series 827S.E/X 11 / 4209.2019 / 1.0

WARNING

Impermissible accessories and impermissible spare parts

Danger of explosion in potentially explosive areas or damage to the

device!

► Use exclusively original accessories and original spare parts.

► Observe all relevant installation and safety instructions described in

the manuals for the device, accessories and spare parts.

WARNING

Open cable entry or incorrect cable gland

Danger of explosion in potentially explosive areas or damage to the

device!

► Seal the cable entries for the electrical connections. Use exclusively

cable glands or blanking plugs for this that are approved for the re-

spective ignition protection class.

WARNING

Exceeding the maximum ambient or media temperature

Risk of explosion in potentially explosive areas

The temperature class of the device is no longer valid if the maximum

permissible ambient or media temperature is exceeded!

► Make sure that the maximum permissible ambient or media temper-

ature of the device is not exceeded.

WARNING

Electrostatic charging of nameplates

The nameplates used on the device can reach a charging capacity of 5

pF.

► Keep the device and the cables at a distance from strong electro-

magnetic fields.

CAUTION

Electrostatically endangered assemblies

The device contains electrostatically endangered assemblies. Electro-

statically endangered assemblies can be destroyed by voltages far be-

low the threshold of human perception. These voltages already occur if

you touch a component or electrical connection without having electro-

statically discharged yourself first. The damage caused to an assembly

due to overvoltage is not usually immediately apparent and only be-

comes noticeable after a lengthy period of operation.

► Therefore, prevent electrostatic charging.

3 Transport, storage and packaging ARCA Regler GmbH

12 / 42 Series 827S.E/X09.2019 / 1.0

3 Transport, storage and packaging

3.1 Transport

Transport at a temperature lower than -40 °C or higher than +80 °C is

not permissible.

3.2 Storage

NOTICE

Improper storage!

There is a danger of the product no longer functioning if it is stored im-

properly.

► Storage at a temperature lower than -40 °C or higher than +80 °C is

not permissible.

► It must be stored in roofed-over storage places and that are weather-

proof.

Openings are sealed with suitable means to prevent the ingress of dirt.

These should be removed by technical personnel at the place of installa-

tion.

CAUTION

Inadequate protection during storage

The packaging offers only limited protection against moisture and infiltra-

tion!

► Provide additional packaging if necessary.

3.3 Packaging

The product is packed in a PE film inside the outer packaging (card-

board box, wooden crate, pallet, lattice box).

If the packaging, in particular the PE film, has been opened, the product

must be stored immediately in a heated room.

The product must be packed in weatherproof or seaworthy packaging for

transport by ship, rail or truck.

ARCA Regler GmbH 4 Type plate

Series 827S.E/X 13 / 4209.2019 / 1.0

4 Type plate

1 2 3

4 5 7 6

8

9

10

Illustration2: 827S nameplate

1 Manufacturer

2 Device name

3 Type

4 Observe the operating manual

5 Protection class

6 Approval

7 ATEX marking for potentially explosive areas

8 Internal capacitance

9 Internal inductance

10 Fabrication number

5 Type key ARCA Regler GmbH

14 / 42 Series 827S.E/X09.2019 / 1.0

5 Type key

827S. X 2 1

[1] [2] [3] [4]

1. Series

827S.

2. Explosion protection 1)

E not explosion proof

X explosion protected "ia" 1)

3. Number of slot-type initiators

1 1 slot-type initiator

2 2 slot-type initiators

3 3 slot-type initiators 2)

4. Types of slot-type initiators

1 SC 3.5…NO…-BU

2 SJ 3.5-SN

3 SB 3.5-E2 2)

1) ATEX approval, other approvals on enquiry

2) only in explosion protection class "E": not explosion proof

Example of type designation 827S.X21

Signal box 827S – explosion-proof "ia" – 2 slot-type initiators – initiators

type SC 3.5…NO…-BU

ARCA Regler GmbH 6 Description

Series 827S.E/X 15 / 4209.2019 / 1.0

6 Description

6.1 Function

▪ The signal box 827S is used for the feedback of up to 3 freely ad-

justable valve positions (positions of the actuator) to the control sys-

tem. The stroke or rotary movement of the actuator is transmitted to

a shaft by the stroke or rotary angle sensor. This rotary movement is

transmitted directly to an immersion disc. The movement of the im-

mersion disc into or out of the respective slot-type initiator generates

the corresponding electrical signal.

▪ The slot-type initiators can be arranged in arbitrary positions around

this immersion disc and adjusted so that almost any desired switch-

ing position is representable for the slot-type initiator.

6.2 Construction

This section describes the mechanical and electrical construction, the

device components and the principles of the operation of the signal box.

The signal box is used to signal the positions (usually the end positions)

of:

▪ linear actuators or

▪ rotary actuators VDI/VDE 3845

Linear actuators may be mounted in a number of ways.

▪ NAMUR or IEC 60534

▪ integrated mounting (ARCA, SAMSON)

The signal box can be mounted and operated on all normal actuators.

The device is available for single-acting and double-acting actuators as

well as for potentially explosive and non-potentially explosive applica-

tions.

6 Description ARCA Regler GmbH

16 / 42 Series 827S.E/X09.2019 / 1.0

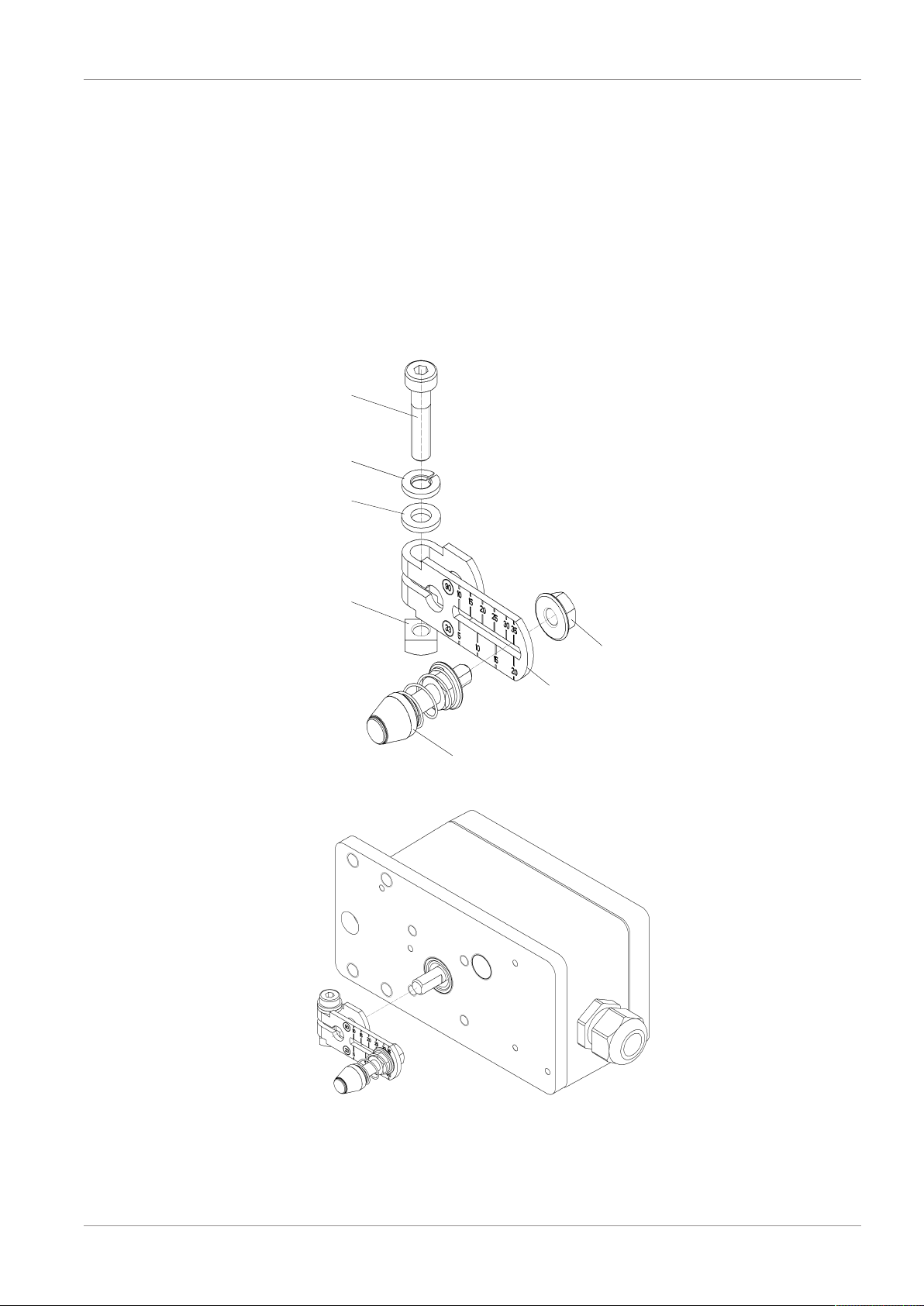

6.3 Device Components

Illustration3: Construction

10 Cable gland

20 Terminal set

30 Proximity switch

40 Screw

50 Washer

60 Screw

70 Washer

80 Switching disc

ARCA Regler GmbH 6 Description

Series 827S.E/X 17 / 4209.2019 / 1.0

90 Circlip

100 Washer

110 Spring washer

120 Spacer sleeve

130 Base plate

6.3.1 Electrical Connections

The signal box's connecting terminals are located on the left-hand side.

7 Assembly ARCA Regler GmbH

18 / 42 Series 827S.E/X09.2019 / 1.0

7 Assembly

7.1 Safety instructions for assembly

CAUTION

Improper installation

Improper installation can result in damage to the device, its destruction

or the impairment of its function.

Ascertain that the device shows no visible signs of damage each time

before installing it.

Ascertain that the process connections are clean and that suitable seals

and cable glands are used.

Install the device using suitable tools.

ATTENTION

The device protection class becoming null and void

Damage to the device due to open or improperly closed housing. The

protection class specified on the nameplate is no longer guaranteed.

CAUTION

Humid environment

If the environment is humid, mount the signal box in such a way that

there is no chance of the shaft freezing at low ambient temperatures.

Make sure that water does not enter an open housing or screw connec-

tion. If the signal box cannot be immediately and permanently mounted

and connected on site, it is possible for water to enter.

7.2 Mounting a linear actuator

7.2.1 Mounting with mounting kit for "Integrated Fitting Linear Actuator"

Included with the "integrated fitting linear actuator" are (see figures be-

low for serial numbers):

Serial

no.

No. of

items

Name Note

1 1 Driver pin cpl. with roller mounted on lever (2)

2 1 Lever

3 1 Washer B6.4 - DIN 125 - A2

4 1 Spring lock washer A6 – DIN 127- A2

5 1 Cylinder screw M6 x 25 - DIN 7984 -

A2

6 1 Hex nut M6 - DIN 6923 – A2

7 1 Square nut M6 - DIN 557 - A4

8 2 Cylinder screw M8 x 65 - DIN 912 - A2

9 2 Spring lock washer A8 - DIN 127 - A2

Mounting procedure (see

figures below) 1. Fig. 5: Adjust the pin (1) on the previously assembled lever (2) to the

value of the stroke range given on the actuator or, if this is not avail-

able as a scale value, to the next larger scale value. In case of un-

ARCA Regler GmbH 7 Assembly

Series 827S.E/X 19 / 4209.2019 / 1.0

certainty with regard to the actual working stroke (pneumatic actuat-

ors often have a setting distance reserve), the next larger scale value

should be selected. The centre of the pin should rest on the scale

line on the lever (2).

2. Fig. 6: Push the lever (2) to the stop on the signal box shaft and fix it

with cylinder screw (5).

3. Hold the signal box against the actuator in such a way that the roller

passes between the pins (16).

4. Align the signal box horizontally on the yoke and assemble it with the

screws (8) and spring lock washers (9).

Assembly procedure plan -

integrated fitting

5

4

3

7

1

6

2

Illustration4: Lever mounted

Illustration5: Mounting the lever on the signal box

7 Assembly ARCA Regler GmbH

20 / 42 Series 827S.E/X09.2019 / 1.0

16 9

8

Illustration6: Mounting the signal box on the actuator

7.2.2 Mounting with mounting kit "Linear actuator IEC 60534"

Included with the mounting kit "Linear actuator IEC 60534", stroke 3 to

35 mm, are (see figures below for serial numbers):

Serial

no.

No. of

items

Name Note

1 1 Driver pin cpl. with

roller

mounted on lever (2)

2 1 NAMUR lever For stroke range 3 mm to 35 mm,

or (order separately for stroke

range > 35 mm to 130 mm, see

Fig. 10)

3 2 Washer B 6.4 - DIN 125 - A2

4 3 Spring lock washer A6 - DIN 127 - A2

5 3 Cylinder screw M6 x 25 - DIN 7984 - A2

6 1 Hex nut M6 - DIN 6923 - A2

7 1 Square nut M6 - DIN 557 - A4

9 6 Spring lock washer A8 - DIN 127 - A2

17 1 NAMUR mounting

bracket IEC 534

Standardised connecting location

for mounting bracket with rib,

column or flat surface

18 1 Sensing hoop Guides the roller with the driver

pin and turns the lever arm

19 2 Clamping piece Assembly of the sensing hoop to

the actuator's stem

20 2 U-bolts Only for actuators with columns

21 2 Hex screw M8 x 16 - DIN 933–A2

22 6 Washer B 8.4 - DIN 125 - A2

23 4 Hex screw M8 x 20 - DIN 933–A2

24 4 Hex nut M8 - DIN 934 - A4

Mounting procedure (see

figures below) 1. Fig. 9: Assemble the clamping pieces (19) using the cylinder screws

(5) and spring lock washers (4) to the actuator stem.

This manual suits for next models

14

Table of contents