Archer Instruments, LLC www.archerinstruments.com

4) It is generally not necessary to remove the VRA-600 guide pin for routine

maintenance. Simply replace the OA-VIT-006 o-ring. However, the guide pin can be

unscrewed by hand or (if necessary) by using a pair of pliers.

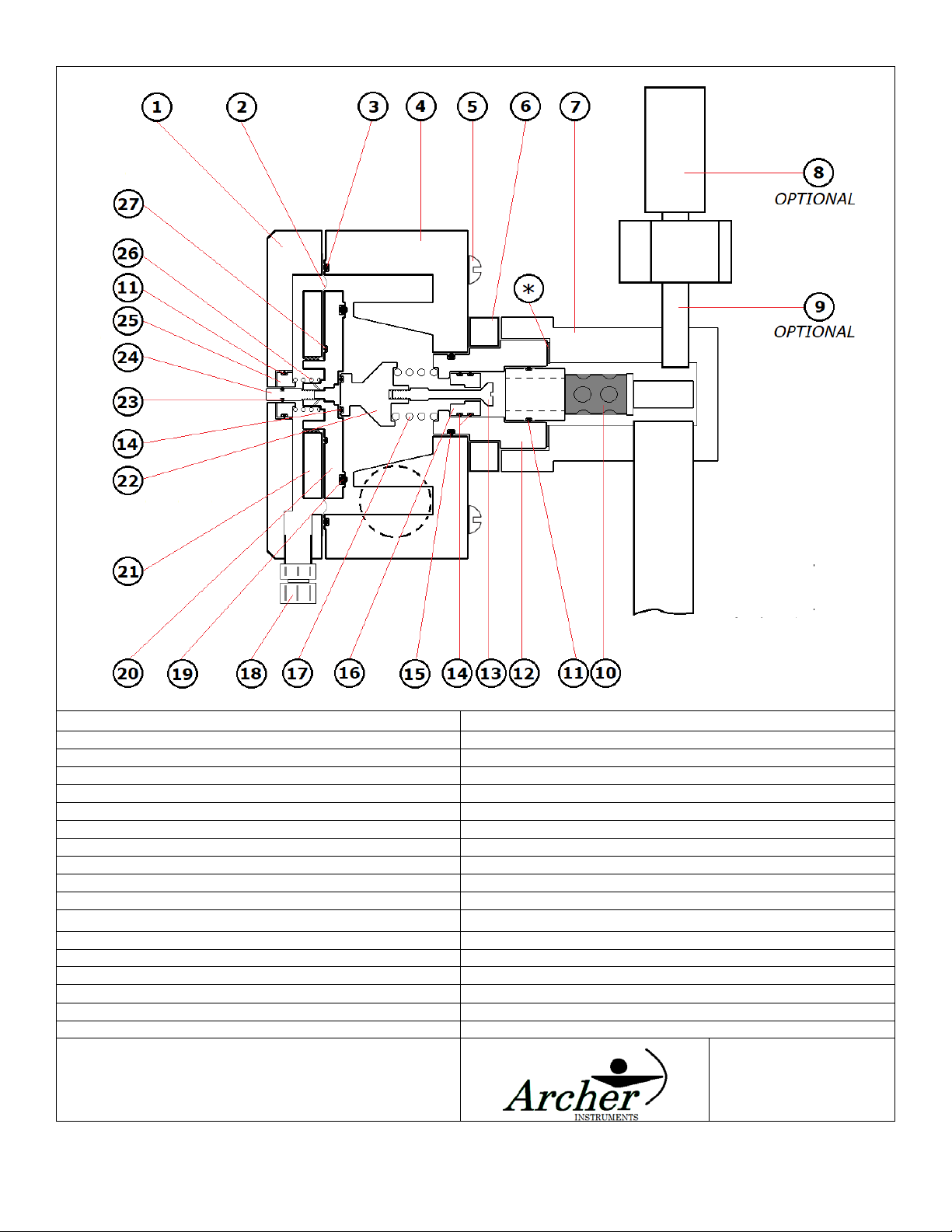

5) The diaphragm back plate VRA-56A and diaphragm front plate VRA-269 are threaded

together and can often be unscrewed by hand. If they will not unscrew by hand, it

may be necessary to use a vice and / or channel locks.

6) To complete disassembly of the back body and inlet valve assembly:

a. Remove the VRA-644 filter holder from the inlet capsule by pulling it straight

out. It is held only by an o-ring fit. It may be necessary to use pliers to twist

and pull the VRA-644.

b. Remove the old LGA-3 lead gasket by carefully prying it away from the VRA-645

inlet capsule.

c. Using a flat head screwdriver, carefully unscrew the inlet valve stem VRA-647

from the spring retainer VRA-649. Remove the stem, spring retainer and SPA-

639 inlet spring.

d. The inlet capsule VRA-645 and back plate VRA-646 can be separated from the

back body VRA-641 using a mallet or similar implement to tap on the inlet

capsule from the inside of the back body.

e. The inlet capsule is press-fit into the back plate. Once they are separated from

the back body, the inlet capsule can be pressed or knocked out of the back

plate.

f. The inlet valve seat VRA-648 is o-ring fit into the inlet capsule and can be

pressed or tapped out of the capsule. The inlet valve seat should always be

replaced during maintenance.

7) The filter holder VRA-644 incorporates a wrapped silver screen through which all gas

entering the unit must pass before reaching the inlet valve. This screen can be

cleaned in place using compressed air, hot water, etc. If necessary, the screen can be

carefully removed and cleaned using a solvent such as acetone. If the screen is

damaged or torn the VRA-644 should be replaced.

8) Whenever routine maintenance is being performed, all parts should be thoroughly

cleaned. It is recommended that the inlet valve seat and all o-rings (with the

exception of the OA-VIT-332) be replaced.

9) When reassembling, new o-rings should be given a thin film of the Fluorolube grease.

SAFETY NOTE:The inlet valve assembly is a critical component of the VR2K. Improper

handling or reassembly can result in dangerous leakage of chlorine gas. Archer

Instruments recommends that only trained personnel or those familiar with

vacuum regulator maintenance service the VR2K.

-Should you have any questions during maintenance of your VR2K vacuum regulator, please

contact your local service provider or Archer Instruments for support.